|

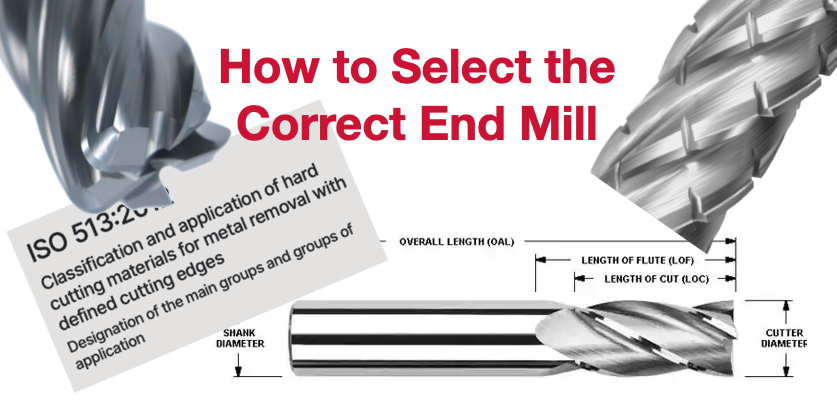

Explore the role of end mill components in machining various materials with our guide on selecting the right features based on ISO 513 classifications, enhancing machining efficiency and tool life. The components of an end mill play a crucial role in determining its performance and suitability for machining different materials. The best way to understand the importance of different features of an end mill is start with the material you are cutting. Just like a butter knife is not good for cutting steak, selecting features for an end mill is very dependent upon the material you're cutting. Let's start with some background information. The ISO 513 is a standard that classifies materials based on their machinability and provides guidelines for cutting speeds, feeds, and tool selection. ISO 513 provides a classification system for the machinability of materials, organizing them into categories based on the characteristics which influence their behavior during machining processes. The main categories include:

Now, let's dig into the details. Below you'll find the key components of an end mill and how they relate to machining different ISO 513 material types:

End Mill Anatomy OverviewThe anatomy of an end mill refers to its various components and features, each of which plays a critical role in its cutting performance. End mills are rotary cutting tools used in milling operations to remove material from a workpiece.

Here's a breakdown of the key parts of an end mill:

0 Comments

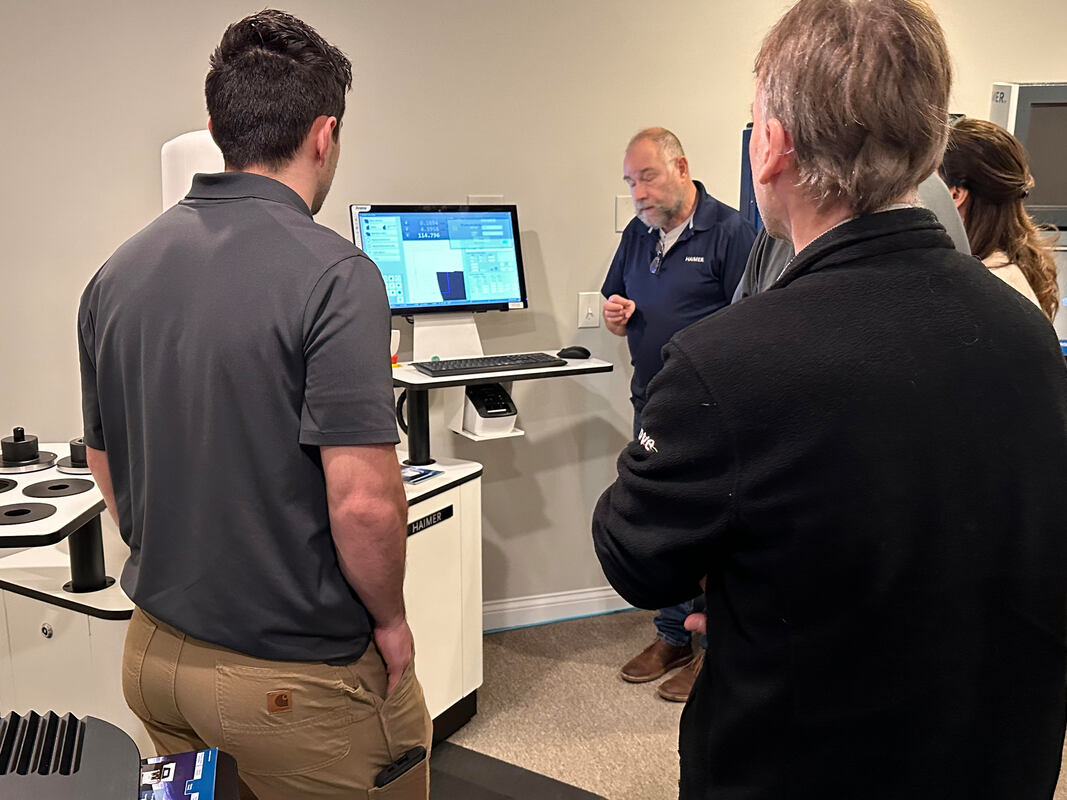

Innovative Facility Showcases the Latest in Metalworking Precision and Efficiency Chardon, OH. - Browne & Company, a leader in the metalworking industry, is proud to announce the grand opening of its new Metalworking Technology Center in Northeast Ohio. This state-of-the-art facility is set to revolutionize the metalworking sector with its cutting-edge technology and tooling, provided by the renowned Haimer presetting and shrink fit tooling. You can also find the latest high performance cutting tools displayed from Fullerton Tool, Regal Cutting Tools, Rocky Mountain Twist Drill, The Everede Family of tooling, Dapra, and others. The Technology Center is designed to meet the growing demands for higher precision, efficiency, and performance in metalworking. It is equipped with the latest advancements in Haimer technology and tooling, ensuring consistent set-up, unsurpassed machining accuracy, better tool life, and improved part finishes. The center represents a significant investment in innovation and demonstrates Browne & Company's commitment to advancing the metalworking industry. "We are excited to unveil our new Technology Center, which symbolizes our dedication to providing the best in metalworking solutions," said Dave Browne, President of Browne & Company. "This facility not only showcases the latest in technology and tooling but also serves as a hub for innovation, collaboration, and education." The Technology Center boasts an impressive display of the latest high-performance cutting tools from leading manufacturers, including Fullerton Tool, Regal Cutting Tools, Rocky Mountain Twist Drill, The Everede Family of tooling, Dapra, and many others. These partnerships underscore Browne & Company's commitment to quality and excellence in providing comprehensive solutions to its clients. Industry professionals, clients, and partners are invited to explore the capabilities of the new Technology Center and witness firsthand the advancements in metalworking technology. Browne & Company is offering personalized demonstrations to showcase the benefits and efficiencies that their state-of-the-art technology and tooling can bring to any operation. "To see the future of metalworking, we invite you to visit our Technology Center. Our team is ready to demonstrate how our latest technologies and tooling can enhance your operations," added Browne. Schedule a Demonstration Don't miss the opportunity to experience the latest in metalworking technology and innovation. Click the button below to schedule a demonstration with our team and discover how Browne & Company can elevate your metalworking projects. About Browne & Company

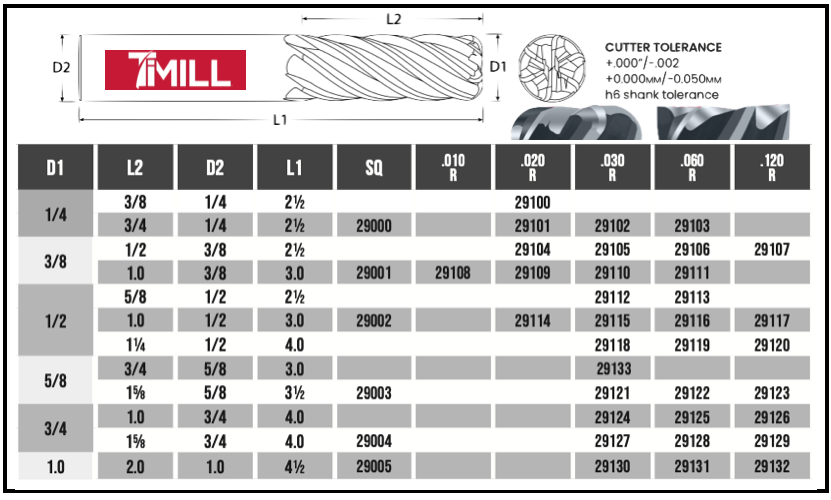

Browne & Company has been at the forefront of the metalworking industry, offering innovative solutions and high-quality tooling to clients across various sectors. With a focus on precision, efficiency, and reliability, Browne & Company continues to lead the way in metalworking technology and services. 3125 V-MAC End Mill is unmatched Performance in High-Temp Alloys and Stainless Steels At Browne & Co, we are thrilled to introduce the latest addition to our cutting-edge tool lineup – the Fullerton Tool 3125 V-MAC End Mill. Engineered to perfection, this high-performance end mill has proven its mettle in milling aerospace high-temp alloys, stainless steels, and inconels, offering unsurpassed performance that sets it apart in the machining industry. The 3125 V-MAC high-performance end mill is your solution for tackling high cutting forces with ease. Designed for precision milling in aerospace materials inclduing high-temp alloys, stainless steels, and inconels, this tool delivers ultimate part finishes and reliable performance. 5 things you should remember about the new 2135 V-Mac!

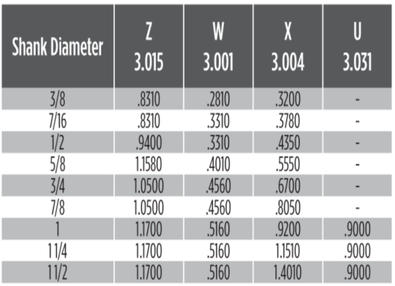

3125 V-MAC Technical Specifications & Options

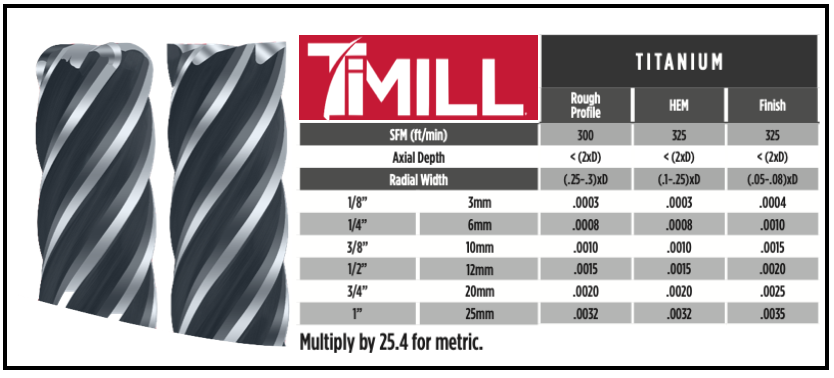

Experience the power of the Fullerton Tool 3125 V-MAC End Mill. Whether you're milling aerospace high-temp alloys, stainless steels, or inconels, this high-performance tool is engineered to exceed your expectations. Elevate your machining capabilities and achieve unparalleled results by getting started with the V-MAC today! Just click the button below! Looking for an end mill with unsurpassed performance in high-efficiency milling of Titanium? The new Fullerton 3116 TiMill end mill may be just what you need. Titanium is half the weight of steel and twice the strength of aluminum: It's a high strength, light weight material with excellent fatigue performance, super durable in high stress environments and corrosion resistant.  As a result of titanium's material properties it's making it become evermore popular in the aerospace, defense, shipbuilding, medical adn dental industries. It's also what makes it considered a "more difficult to machine" material. Let's dig into that a bit more. Generally, titanium grades 1 through 4 are considered commercially pure titanium with varying requirements on ultimate tensile strength while Grade 5 is what is most often seen in the machining industry. It's often alloyed with 6% aluminum and 4% vanadium. This is what is commonly known as 6Al4V or Ti 6-4. Also quite common is 4Al4V or Ti 4-4. Why difficult? Well, first it has low Young’s modulus meaning that is more elastic than other materails: It's "gummy" which often causes spring back and chatter during machining and can readily generate long stringy chips if you don't have the correct edge prep. On top that, it's also prone to work hardening and galling super easily. You've got to keep the cutter in-the-cut: Insert cutters just aren't as good as solid endmills at doing this. Next, titanium does not have good thermal conduction properties like aluminum. Instead of heat being evacuated in the chips or transferred to the base material, heat tends to be transferred to the cutting tool which reduces it's tool life. Heat kills. Tool life declines. The right coating helps. The final icing on the cake is that titanium is prone to work hardening. During uniaxial loading, the initial rate of hardening is higher in compression so if you come back for another pass you need to get under the work hardened layer, that is, leave enough material for a finish pass to get under the layer or your tool life will suffer and your part finishes will decline with it. Ideally, finish to size in the final pass if you can. The trick to machining titanium has always been to keep consistent coolant flow to evacuate the chips and maintain a consistent chip load. Again, rough to your finish size. Don't let it work harden. That's what we've learned about titanium over the past couple of decades. There has been a ton of research on titanium's properties and that research has led to further refinement of the cutting tool geometry at Fullerton. The design of Fullerton's 3116 TiMill is based upon over a decade of aerospace testing and development and addresses many of the machining issues that Titanium presents. It's a 6-flute tool built with a 38°helix. The increased number of flutes allows for the tools to remain "in the cut" longer and more consistently. It doesn't induce as much heat as a lower number of flutes tends to do. instead, it's consistent. The 38°helix evacuates the chip at a more optimum angle than a 35°, 37.5° or 40° helix that predecessors made by competitors have tried.

Speeds and Feeds are Critical* IT'S MADE FOR TITANIUM! So that means it is NOT Recommended for High Si Aluminum (>10%), Low Si Aluminum (<10%), Composites, Plastics, Brass & Copper, or Graphite. NOT Recommended! Choose your SizeChoose from Fullerton’s selection of carbide reamers with Just-In-Time offering that includes manufacturing any size reamer within 24 hours.

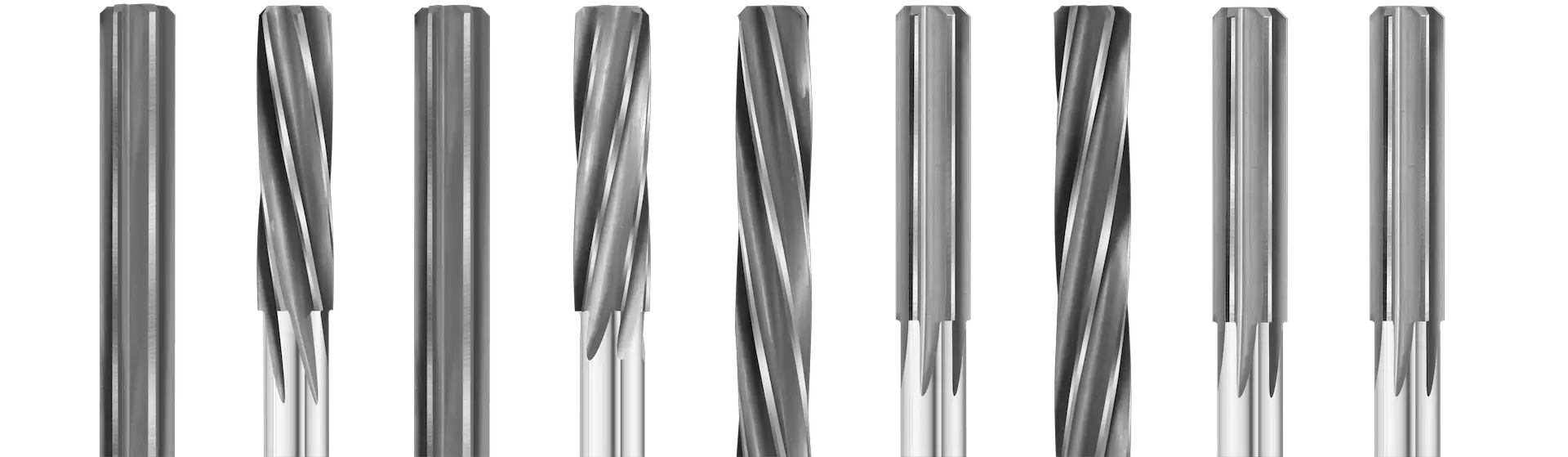

Fullerton’s carbide reamers are designed for numerous reaming applications and for a variety of materials including titanium, super alloys, hardened steels, stainless steels, steels, cast iron, graphite, brass & copper, hi silicon aluminum, low silicon aluminum, composites, plastics, and wood. Reamers are manufactured to support customers in numerous industries, including aerospace, automotive, heavy equipment, medical, and mold & die. Ready to ship within 24 hours! Sign up below for your own login at Fullerton Tools award winning website IMTS 2022 Preview: Arno, Fullerton, Everede, Haimer & Precision Brand to Feature New Products!9/8/2022 If you're making plans to attend IMTS, be sure and add this group of terrific manufacturers to your your show planner! Just click on the name, building location or image and you can add them to your "MyShowPlanner" ARNO-Werkzeuge USA LLCARNO FAST CHANGE: Make More Parts Per Shift On Your Swiss Machine How do you increase spindle up-time on your sliding head Swiss lathe?

Fullerton ToolManufactures High Performance Solid Carbide Round Cutting Tools. Endmills, Drills, Reamers, Saws, Burrs, Keyseat Cutters, PCD, and Custom Special Tools.

Everede Tool Co.Everede is a Manufacturer of Indexable Boring Bars and Inserts. Catalog includes Steel, Carbide, Carbide Bars andmore Exclusive USA representative for Nine9 and Duemmel. Nine9 manufacturer’s high quality unique indexable Engraving, Spotting... Duemmel manufacturer’s high quality Indexable carbide cutting tools for micro boring, grooving Haimer USAHAIMER is a first class German Tool Holder manufacturer. From the basics of face-mill arbors and ER collet chucks, all the way up to High Precision Collet and Shrink Fit Chucks, HAIMER has the tools necessary to satisfy and exceed your machining center needs. Their product line includes the most extensive taper and size offerings from any HSK, CAT, BT, SK, PSC and KM tapers to any inch or metric size available. Their product portfolio, which also holds shrink fit, presetting & balancing machines, 3D-sensors, and cutting tools, addresses the machining process from spindle to part, giving the customer a complete machining solution. Precision Brand Products, Inc.For over 75 years, Precision Brand Products has been the benchmark for toolroom products. Our product line of over 2800 products, including shim stock, feeler gauges, key stock, hose clamps and more, has kept pace with the changes and advances in manufacturing technology and methods worldwide.

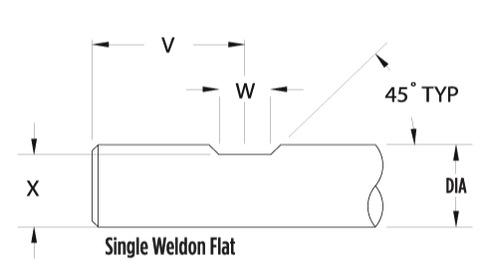

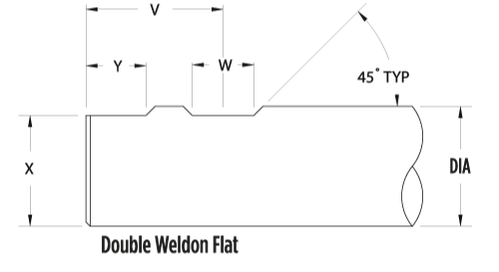

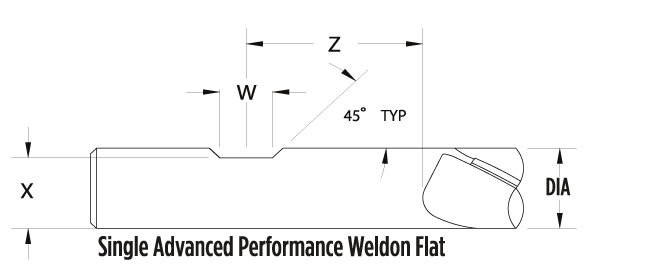

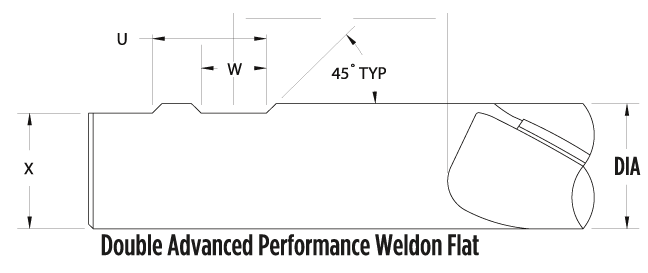

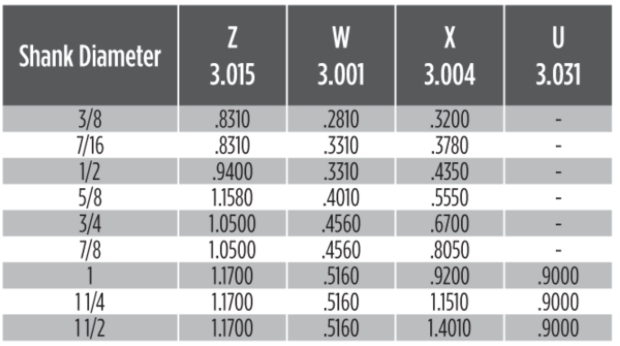

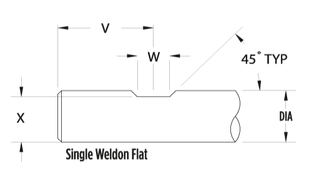

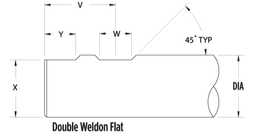

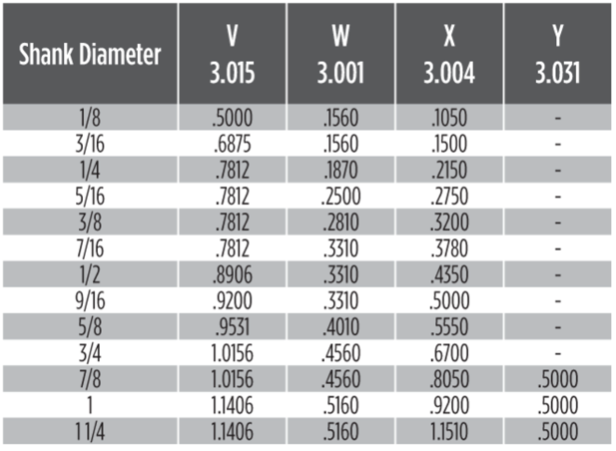

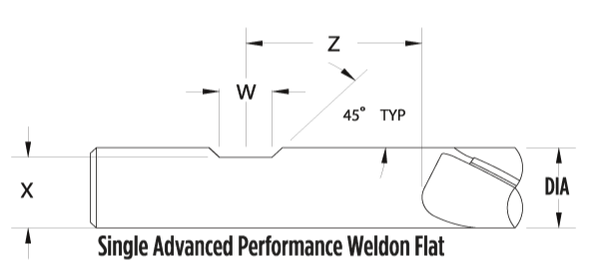

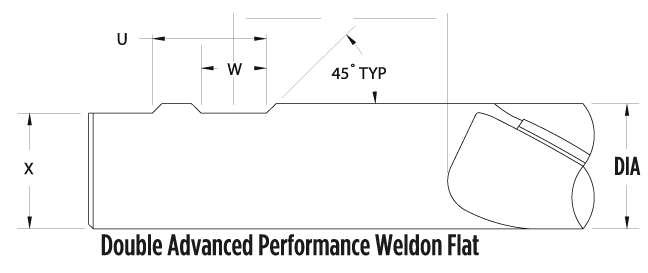

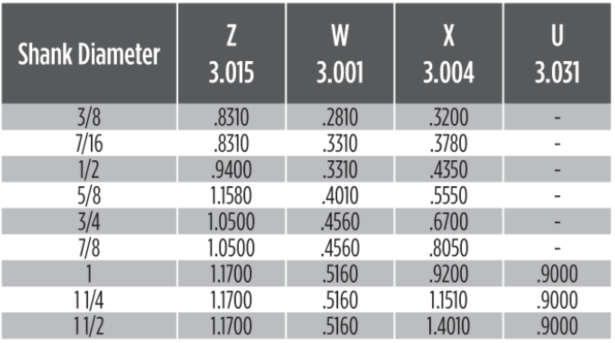

In 1918, Carl A. Bergstrom opened the Weldon Tool Co. in Cleveland. Working from his shop atop the Blackstone Building, he developed a new kind of endmill with a 30° helical flute. The thing cut like crazy. Bergstrom quickly realized that his toolholder lacked the gripping power to hang onto his cutting-edge endmill, as the thing kept spinning right out of the holder. He took the end mill and ground a flat spot on its side of it's shank, giving the toolholder’s clamping screw a place to bite into. Bergstrom had invented the Weldon flat shank.  Fullerton Tool Standard Weldon Flat Fullerton Tool Standard Weldon Flat A Weldon flat is a flat section on a tool shank. When placed in a Toolholder the flat on the shank is held in place by set screws within the body of the holder. Using this flat, a set screw securely holds the tool and prevents the tool from rotating when machining. Weldon flat tools are predominately used when milling but can be used in other applications. When rough machining and removing large amounts of material, Weldon flat holders can be beneficial. Particularly in the Aerospace sector when machining parts such as expensive wing spars, tool pullout can occur which can be very costly and damaging. When machining materials such as Titanium, optimal machining parameters produce high torque forces on the cutter, Titanium requires an aggressive depth of cut at relatively slow spindle speeds and Weldon Flat holders are ideal for these types of applications. However, Weldon Flat tools do have their disadvantages. Weldon-style endmill holders by their design push the cutter off centre which creates runout and can drastically reduce tool life. Tool Balancing (or imbalance) can also be a problem. Fullerton Tool offers both Standard Weldon Flat and Advanced Performance Weldon FlatAt Fullerton Tool they have 2 types of Weldon Flats available - the Standard Weldon Flat and the Advanced Performance Weldon Flat.

The Standard Flat (WF) and the Advanced Performance Weldon Flat (AF) are essentially the same, but the length of the Weldon Flat to the cutting tool is different. The Advanced Performance Weldon Flat (AF) is measured from the flute washout to the flat. This guarantees that the flute or flute washout will not be inside of the holder. If the flute or flute washout is inside the tool holder, the chips can pack into the holder and cause the tool to break. Guest Blog by Mark Donze at Fullerton Tool Have you ever wondered if you should purchase high-performance end mills or general-purpose end mills and what the benefit of purchasing one over the other is? If so, we have put together a list of factors to consider to help you make the right decision for next time. General Purpose End MillsFirst, let's discuss general purpose end mills. General Purpose (GP) End Mills are standard single, 2, 3, or 4 flute geometry end mills made for use in a wide variety of materials. Benefits of General Purpose End Mills:

High-Performance End MillsNext, High-Performance (HP) End Mills contain specialized geometries for a specific material being cut. Benefits of High-Performance End Mills:

With this information in mind, if you are a company that does small runs in a wide variety of materials you may prefer GP end mills. Whereas, if you are making high-volume parts where cycle-time and up-time are king, you may prefer an HP end mill for your use. Remember, there are no hard lines drawn. Each application is different and preference is ultimately up to you, the end-user.

If you aren't sure, you can contact your Fullerton authorized distributor to help make this decision. We will work with you to get the end results you desire with a wide variety of both GP and HP end mills available. We even have some tooling where we apply HP coatings to GP tools to help you get the most out of your cutting tool investments. We have a huge selection of inventory items and of course, if you need a special tailored tool to your specific needs, we have engineering and application knowledge to get the most out of your cutting tool budget. We also have resources on our website to help you navigate which tool is the best for your needs. Discover what end mills are recommended for your material and application by using the Fullerton Tool End Mill Selection Guide You can also explore and search for tooling by material, application, or tool specs as well as recommended speeds and feeds by series which you can access at the search button below. Fullerton Tool, offers two types of Weldon Flats: The Standard Weldon Flat (WF) and the Advanced Performance Weldon Flat (AF)

They are essentially the same, but the length of the Weldon Flat in relationship to the cutting tool is different. The Advanced Performance Weldon Flat (AF) is measured from the flute washout to the flat. This guarantees that the flute or flute washout will not be inside of the holder. If the flute or flute washout is inside the tool holder, the chips can pack into the holder and cause the tool to break. Visit Browne & Company in Booth 2088 This year at PMTS, our Booth # 2088 will be featuring Advanced Chemical Solutions, Fullerton Tool Company, and Everede Tool Company. Understanding the relationship between cutting tools and metalworking fluids provides us with an advantage you will not find with any other exhibitor, an advantage that you can put to work for you. Friendly members of our team will be ready to answer any questions you might have. To check out Booth 2088 in person, be sure to register for PMTS below! Hope to see you there! |

AuthorWe've compiled the latest news and technical information about our principals and our market that we hope you find informative! Archives

June 2024

Categories

All

|

|

Browne & Co., Inc.

9605 Tanager Drive Chardon, Ohio 44024 |

© 2024 Browne & Co., Inc. All Rights Reserved

web design by Rapid Production Marketing |

RSS Feed

RSS Feed