|

by Bernard Martin For metalcutting professionals achieving precision in small bore machining has always been a challenge. The Dümmel Ultramini tool-line is designed to meet this challenge head-on, offering an unparalleled solution for turning the smallest bores with ease and precision. This article is going to explain some of the unique features of the Dümmel Ultramini and compare it to some of the other competitors products in the market. Why Choose the Dümmel Ultramini? The Dümmel Ultramini tool-line stands out for several key reasons, making it a great choice for small bore machining. First, the sharp cutting edges of Ultramini tools result in extended tool life, reducing the need for frequent replacements and minimizing downtime. The special cooling channel ensures a stable and eccentric shank part, enhancing overall performance and durability. Some sizes within the Ultramini range offer a superior length-to-diameter ratio when compared to competitors such as P.H. Horn, Simtek, and Gühring, making the Dümmel Ultramini ideal for deeper and more precise cuts. Generally, toolholders for the Ultramini are less expensive compared to those of other brands, offering a more economical solution without compromising on quality. We'll dig into to some of those details below as well. In the U.S., through their exclusive collaboration with Everede Tool, Dümmel stocks G holders with a precision of 0.0004", compared to the 0.0008" precision of competitors. With over 1,000 different standard inserts, the Ultramini line boasts one of the largest standard product ranges available, ensuring that you can find the perfect tool for your specific needs. The Ultramini range includes a variety of inch-size threading and grooving tools, catering to the diverse needs of the industry. Lastly, the innovative clamping system, with the clamping flat positioned on top of the insert’s shank, ensures a secure and precise hold during operation. Competitive ComparisonWhen compared to major US competitors, with P.H. Horn, Simtek and Guhring, the Dümmel Ultramini tool-line offers distinct advantages over several competitors. Below is breakdown of how Ultramini competes. Compatibility with ISCAR PiccoCut Jet Line Before we take a deep dive into the competitors products let's talk about compatibility. A key advantage of the Dümmel Ultramini tools is their compatibility with ISCAR PiccoCut Jet Line holders. This compatibility ensures that customers can seamlessly integrate Dümmel tools into their existing setups, maximizing their investment and operational efficiency. Dümmel vs P.H. Horn The Dümmel Ultramini coupling system offers a distinct advantage over the P.H. Horn coupling system in terms of the number of set screws and the clamping method. The Dümmel Ultramini uses two set screws to secure the insert. These set screws clamp onto a flat ground surface on the insert’s shank, ensuring a secure and precise hold. This design provides stability and reduces the likelihood of insert movement during operation, resulting in more accurate machining and longer tool life. In contrast, the P.H. Horn coupling system uses a different clamping method. It typically relies on a single set screw that clamps onto the radius of the carbide bar. This method is less stable compared to the Dümmel system because clamping onto the radius can allow for slight movements and misalignments, which can impact the precision of the machining process and potentially lead to quicker wear and tear of the tool. The key differences between the two systems highlight the superior design and functionality of the Dümmel Ultramini coupling system, making it a more reliable choice for small bore machining. Dümmel vs Simtek When comparing Dümmel Ultramini to Simtek, although both offer similar quality and sharp inserts, Dümmel distinguishes itself through several specific engineering advantages and tighter tolerances, as well as the economics of its toolholders and a broader product range. The Dümmel Ultramini toolholders are designed to be more economical without sacrificing quality. The toolholders are simpler and less expansive to manufacture, yet they maintain very high precision. This cost-effective design results in significant savings for users while ensuring reliable performance. Dümmel's toolholders are also engineered with tighter tolerances. For example, the G holders available in the USA have a precision of .0004", compared to Simtek's typical .0008". This tighter tolerance means that Dümmel tools fit more precisely, reducing vibration and improving the accuracy of the machining process. This precision is critical in small bore machining, where even slight deviations can significantly impact the quality of the final product. The Dümmel Ultramini range offers a broader product selection. With over 1,000 different standard inserts, Dümmel provides a comprehensive array of tools to meet diverse machining needs. This extensive range ensures that users can find the ideal tool for their specific applications, whether it involves threading, grooving, or other specialized operations. In contrast, while Simtek has a robust product line, it does not yet seem to match the sheer variety and availability that Dümmel offers. In summary, the combination of economical toolholders, tighter engineering tolerances, and a wider product range gives Dümmel Ultramini a distinct edge over Simtek in small bore machining Dümmel vs Guhring When comparing Dümmel Ultramini tools to Gühring’s offerings, Dümmel stands out for several reasons. Dümmel Ultramini inserts have exceptionally sharp cutting edges, essential for precision in small bore machining. These sharp edges reduce cutting forces, minimize tool wear, and improve surface finish. In contrast, Gühring’s inserts are not as sharp, leading to higher cutting forces and increased wear over time, which can compromise machining quality. Dümmel’s sharper inserts also contribute to longer tool life and better performance by creating less friction and heat during cutting, reducing the likelihood of tool degradation. This results in more consistent performance and fewer tool changes. Gühring’s inserts, being less sharp, may require more frequent replacements and can interrupt the machining process. Dümmel Ultramini tools are designed with tighter tolerances, ensuring a precise fit and stability during machining. This precision is crucial for small bore applications, where minor deviations can significantly impact the final product. Gühring’s inserts, while precise, do not match Dümmel’s level of tight tolerance and stability, affecting machining accuracy. Dümmel Ultramini tools offer sharper inserts, better performance, higher precision, enhanced cooling and stability, and a more targeted product range compared to Gühring, making Dümmel a superior choice for small bore machining applications. Additionally, Dümmel Ultramini tools feature a special cooling channel that enhances stability and prevents overheating, maintaining sharpness and performance even during extended use. Gühring’s tools, although effective, lack the same level of innovation in cooling and stability, which can affect performance in high-demand applications. While Gühring offers a large product range, Dümmel Ultramini provides a more specific and varied selection for small bore machining. Dümmel’s comprehensive range of inserts and toolholders ensures users can find the ideal tools for their needs, whereas Gühring’s broader range may not be as finely tuned to this niche market. Limited Time Promotion!To further entice customers, Dümmel is offering a toolholder swap promotion. Customers can exchange their Horn Supermini and Sandvik CXS toolholders for Dümmel toolholders on a one-for-one basis, regardless of quantity.

The Dümmel Ultramini tool-line is a game-changer for small bore machining, offering unmatched precision, durability, and cost-effectiveness. With its extensive product range and innovative features, the Ultramini line is poised to become the go-to solution for professionals in the metalcutting industry. Don’t miss out on the opportunity to enhance your machining capabilities with Dümmel Ultramini tools. For more information and to take advantage of our promotional offer, contact us directly.

0 Comments

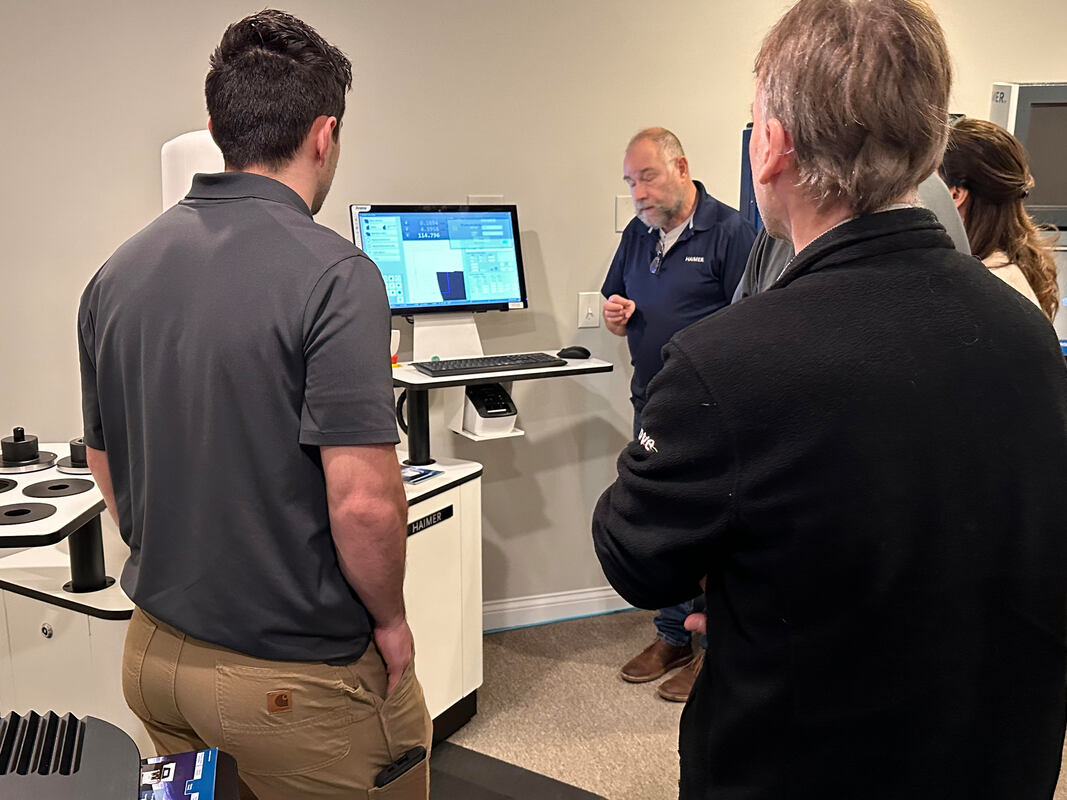

Optimizing Rotary Toolholder Performance: Navigating the Nuances of Balancing Quality and Tolerance6/12/2024 With rotating bodies, imbalance is an omnipresent phenomenon. A typical example are rotating tools on machine tools. Because unbalance creates a centrifugal force, it increases linearly with the unbalance and squares with the number of rounds. The faster the rotor rotates, the more noticeable the unbalance. But how does unbalance arise, how can it be measured and how can it be eliminated by balancing? On the following page we have put together the theoretical fundamentals of balancing, the basis for tool balancing. As a side note to this discussion, there is sometimes confusion over use of the words "imbalance" and "unbalance". Imbalance is the noun meaning the state of being not balanced, while unbalance is the verb meaning to cause the loss of balance. Causes of Unbalance In rotating toolholder, addressing imbalance is crucial for efficiency and longevity. Imbalances arise from uneven mass distribution, design asymmetry, or manufacturing inaccuracies, leading to detrimental centrifugal forces during operation. Balancing, achievable through mass adjustment or component alignment, mitigates these forces. This process involves precise measurement and correction to adhere to industry quality standards, though achieving absolute balance is challenging due to inherent mechanical and environmental factors. Here's a quick overview:

What is Unbalance? Static balance in rotary toolholders refers to the condition where the center of gravity is aligned with the axis of rotation, ensuring no lateral movement when the toolholder is stationary or rotating. Dynamic balance, on the other hand, addresses both the static imbalance and the couple imbalance, ensuring that the toolholder remains stable and does not wobble during high-speed rotation, which involves balancing across two planes. Achieving dynamic balance is crucial for toolholders in high-speed applications to minimize vibration and wear. Let's dig into some details: STATIC UNBALANCE Static unbalance in rotary toolholders manifests when their center of gravity doesn't align with the axis of rotation, leading to centrifugal forces that can cause significant issues when the rotor spins. This kind of imbalance can be detected even in non-moving rotary toolholders and is correctable by adjusting the mass distribution within a single plane. However, correcting static unbalance (a.k.a. Single Plane Balancing) might not address other types of imbalance, like couple unbalance, that can still affect the rotor's operation.

COUPLE UNBALANCE Couple imbalance occurs when a toolholder's center of gravity is aligned with its rotation axis but still experiences a tilting moment during operation due to the distribution of mass. This condition, detectable only when the toolholder is in motion, results from opposing centrifugal forces that create no lateral movement but cause a rotational tilt.

DYNAMIC UNBALANCE Dynamic imbalance in a rotary toolholder refers to a scenario where both static imbalance and couple imbalance are present, causing the toolholder to experience tilting and wobbling during operation. This complex form of imbalance necessitates correction in two planes for the toolholder to rotate smoothly at varying speeds, thereby reducing vibration and wear on associated machinery. In case you were wondering the ideas of dynamic balance was developed by R.S. Berkof, G.G. Lowen in the seminal work A New Method for Completely Force Balancing Simple Linkages. What is "Balancing"?

BALANCING IN A SINGLE PLANE (STATIC BALANCING) Balancing in a single plane corrects the static imbalance by adjusting the toolholder's center of gravity to align with its axis of rotation, minimizing eccentricity. However, this method doesn't correct the couple imbalance associated with dynamic unbalance, which remains unaffected. BALANCING IN TWO PLANES (DYNAMIC or DUAL PLANCE BALANCING) Dynamic or dual plane balancing involves correcting both static and couple imbalances in a toolholder, achieving thorough compensation. The process allows for the selection of any two balancing planes, ideally positioned as far apart as possible, to ensure comprehensive balance throughout the toolholder's operation. Measuring Unbalance The first step in correcting imbalance is to determine where unbalanced mass is located in a single plan or 3 dimensional plane. To do this, the tool holder is inserted into the balancing spindle and made to rotate.

Balancing Quality - G Values The two primary factors to determine permissible unbalance, also called the balancing tolerance, are the mass of the rotating part (G) and the maximum operational speed (RPM). To put a more technically, the grade G values in toolholder balancing are determined based on the permissible residual unbalance for a given rotation speed and the weight of the rotary toolholder, as outlined in standards such as DIN ISO 1940-1 (previously VDI guideline 2060). These values guide the maximum allowable unbalance to ensure operational safety and efficiency, factoring in specific operational conditions. Each grade G value (previously: Q) corresponds to a different level of balancing precision, tailored to the rotor's intended use and operating environment.

Achievable Accuracy Keep in mind that the balancing quality grade is only valid for a specific rotation speed of the the toolholder. e.g. G2.5 at 25,000 RPM. This permissible residual unbalance is calculated from the balancing quality grade, the rotation speed and the weight of the toolholder. Here's the actual formula: Uper = (G•M)/n • 9549

HERE IS AN EXAMPLE

In the above example there is a permissible residual unbalance of 1.3 gmm. To illustrate this value it is useful to convert the unbalance to eccentricity. Uper = M • eper eper = Uper/M =1.3 gmm/800g = 0.0016 mm = 1.6 μm Therefore the centre of gravity of the tool holder can be offset by max. 1.6 μm from the axis of rotation. During balancing the axis of rotation is assumed to be the axis of the taper or HSK. However, in the milling machine the tool rotates about the axis of the spindle. Even new spindles TIR of up to 5 μm (equivalent to eccentricity of e = 2.5 μm). ANOTHER EXAMPLE Balancing quality G = 1 Rotation speed n = 40.000 rpm Tool weight M = 0.8 kg Uper = 0.2 gmm eper = 0.3 μm This permissible eccentricity cannot be achieved in practice. Even good spindles have a repeatability of 1-2 μm when the tool is changed. Even small amounts of dirt, grime or swarf can worsen the result significantly. Complexities of Achieving |

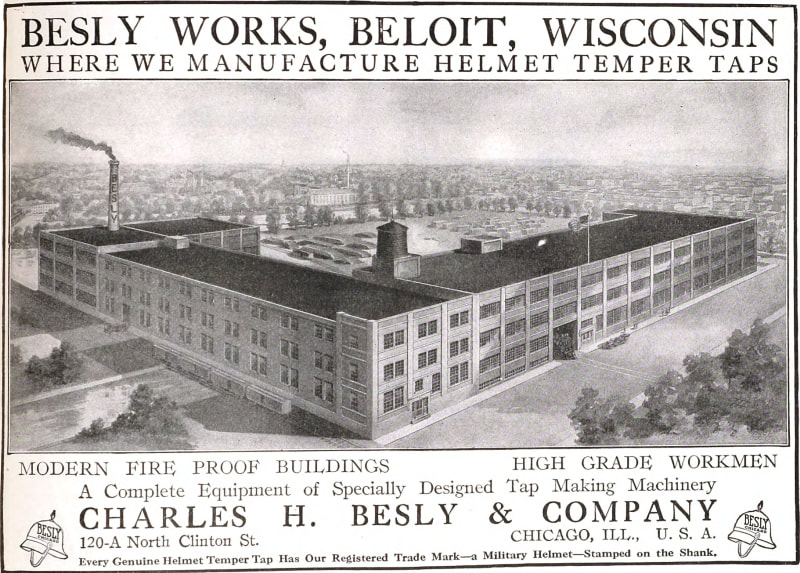

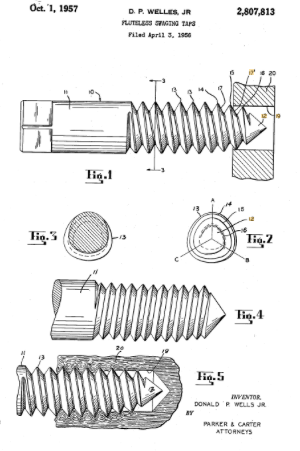

| The Besly-Welles Era Besly was purchased by the Welles family in 1936, and changed the name of company to Besly-Welles Corp. in 1952. Edward P. Welles was the company's first salesman of Besly grinders, and he rose through the ranks to be president of the company following Besly's death in 1908. Until 1950 a cutting tap was the only tool available for the creation of internal threads. In 1950 at least two manufacturers began making swaging taps. In 1957 Besly-Welles commenced marketing its improved "fluteless swaging tap" in regard to which it eventually obtained three patents. Besly-Welles earliest swaging tap patent was issued in 1957 and the final patent on August 28, 1962. Today most people call this "fluteless swaging tap" a "form tap" or a "roll tap". Besly was a part of this innovative piece of thread making history. |

Besly-Welles Corp. was sold to Bendix in 1965, and at the time was enlarged with two other Bendix affiliates, the former Threadwell Tap and Die Co. of Greenfield, Mass., and Scully-Jones and Co. of Chicago. The South Beloit facility acted as headquarters for the industrial tools division.

In September 1984 James A. Deeds, who worked as controller for the company, purchased Bendix' local plant. He changed the name to Besly Corp., and continued manufacturing and distributing cutting tools, including standard and high speed steel taps, drills, reamers, end mills and carbide tipped cutting tools.

In November of 2005 a new company, Besly Cutting Tools, Inc. was established with plans to continue customer service, technical support, inventory, shipping and manufacturing in South Beloit.

In 2005 Besly Cutting Tools, Inc. was acquired by YG-1.

The Beloit Tool Company

| In 1955, Beloit Tool Company started in a vacant roller rink. Similar to other earlier entrepreneurs, the founders saw an opportunity to build a business based on the need of manufacturing companies. Many of these companies required rapid service when they were developing a product with special threads. |

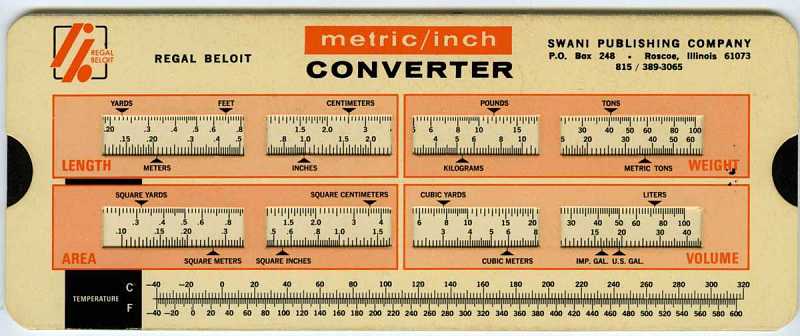

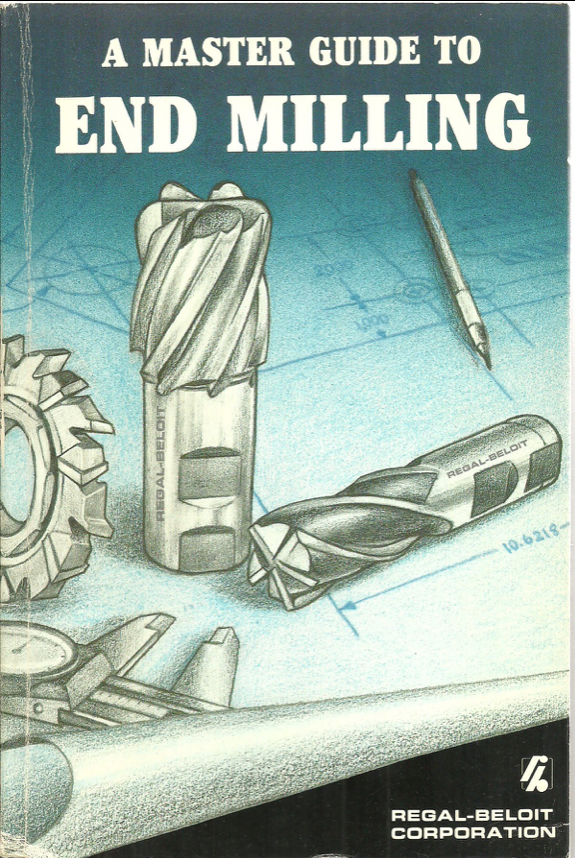

| The company quickly expanded due to its philosophy of fast response times to phone calls, requests for quotations, quick shipments and quality tools.. 24 hour shipment of special taps often resulted in long work days—meaning employees often had to shift work schedules in order for these shipments to be accommodated. Beloit Tool became Regal Beloit in 1969. As the company grew by acquiring other companies, the focus became power transmission equipment, and then electric motors shortly afterwards. The cutting tool operations, though the foundation of this multi-billion dollar corporation, was no longer the company’s main focus. In order to regain its original focus, the company found a buyer who would continue the legacy that was created so many years before. in 2006, YG-1, the world's third largest cutting tool manufacturer acquired the cutting tool division of Regal Beloit and it was renamed Regal Cutting Tools. |

YG-1: A Global Powerhouse in Cutting Tools

The company strategically entered the North American market with an opening of the Chicago office in 1985, marking its commitment to expansion. Notably, YG-1 made key acquisitions in North America, including the acquisition of Besly Cutting Tools, Inc. and Regal Beloit's cutting tool division in the early 200's. The acquisition of Besly in particular enhanced YG-1's capabilities and product portfolio in the North American Markets.

With the addition of Regal Beloit's cutting tool division, YG-1 strengthened its position in North America, showcasing its commitment to innovation and growth in the global market. These acquisitions allowed YG-1 to leverage the expertise and market presence of the acquired companies, contributing to its success as a prominent player in the cutting tool industry.

Iconic Brand Names Live on

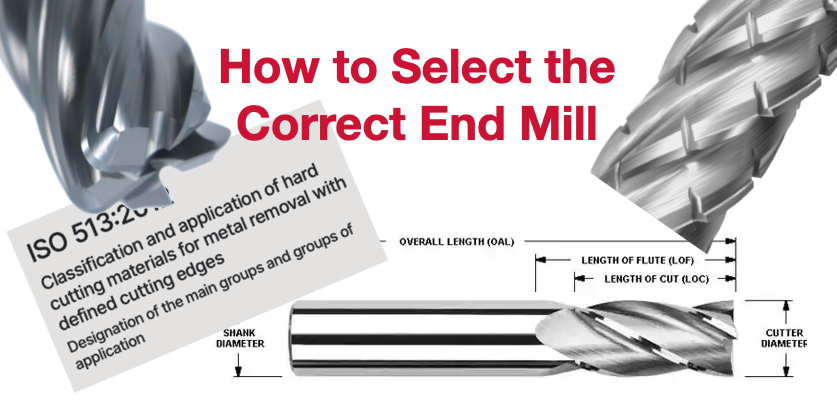

The 3125 V-MAC high-performance end mill is your solution for tackling high cutting forces with ease. Designed for precision milling in aerospace materials inclduing high-temp alloys, stainless steels, and inconels, this tool delivers ultimate part finishes and reliable performance.

5 things you should remember about the new 2135 V-Mac!

- Enhanced Flute Design for Optimal Chip Control: The V-MAC's advanced flute design goes beyond conventional end mills, providing superior chip control. This not only improves the overall machining process but also reduces cutting forces, allowing for aggressive speeds and feeds without compromising on precision.

- Staggered Flute Geometry for Vibration Control: Vibrations can be a significant concern in high-speed machining. The V-MAC's staggered flute geometry is specifically engineered to limit vibrations, ensuring stability and consistency in performance even in demanding applications.

- Engineered Core for Robust Axial Strength: Achieving optimal tool stability is crucial in high-performance machining. The V-MAC is crafted with an engineered core that provides robust axial strength, enhancing its durability and reliability in the face of challenging machining conditions.

- FC-21 Coating for Extended Tool Life: The FC-21 coating on the V-MAC resists fatigue and micro-chipping, resulting in a consistent cutting edge over an extended tool life. This coating ensures that the end mill maintains its peak performance even in prolonged and rigorous machining operations.

- Versatility in Design: The 3125 V-MAC is a versatile solution, available in both square end and corner radius configurations. Whether you need a Stub or Standard length, this end mill caters to your specific machining requirements.

3125 V-MAC Technical Specifications & Options

|

Experience the power of the Fullerton Tool 3125 V-MAC End Mill. Whether you're milling aerospace high-temp alloys, stainless steels, or inconels, this high-performance tool is engineered to exceed your expectations. Elevate your machining capabilities and achieve unparalleled results by getting started with the V-MAC today! Just click the button below!

Choosing the Right Tuffy Products Chain Hoist for Your Application: A Comprehensive Guide

12/12/2023

Tuffy Products, a one of the most reputable manufacturers of high-quality lifting and material handling equipment, offers a range of chain hoists tailored to various applications.

In this guide, we' ll explore the key factors to consider when choosing the right Tuffy Products chain hoist for your needs.

Determine Your Lifting Requirements

The first step in selecting the correct chain hoist is to define your lifting requirements. Consider the following factors:

- Load Capacity: Calculate the maximum weight you need to lift. Ensure that the chain hoist's capacity exceeds this weight to allow for a safety margin.

- Lift Height: Determine the vertical distance the load needs to be lifted. Tuffy Products offers chain hoists with varying lift heights, so choose one that meets or exceeds your requirements

Understand Your Application

The type of application plays a significant role in selecting the right chain hoist. Consider the following applications and their specific needs:

- Industrial: For heavy-duty industrial applications, look for a chain hoist with a robust design, high load capacity, and durable materials. Tuffy Products offers chain hoists suitable for demanding industrial environments.

- Construction: Construction sites often require portable and versatile chain hoists. Look for features like lightweight construction and ease of transport when selecting a hoist for construction applications.

- Entertainment and Rigging: In entertainment and rigging applications, precision and control are crucial. Choose a chain hoist with smooth operation and precise load control.

Consider Your Working Environment

The environment in which the chain hoist will operate is essential for making the right choice:

- Corrosive Environments: If your application involves exposure to corrosive substances, such as saltwater or chemicals, opt for a chain hoist with corrosion-resistant materials or coatings.

- Explosive Atmospheres: In potentially explosive environments, ensure that the chain hoist is rated for hazardous locations, typically indicated as "ATEX" or "Explosion Proof."

Evaluate Chain Hoist Types

Tuffy Products offers different types of chain hoists, including manual chain hoists and electric chain hoists. Consider which type best suits your needs:

- Manual Chain Hoists: Ideal for applications where precise control and slower lifting speeds are acceptable. They are typically more cost-effective and do not require electrical power.

- Electric Chain Hoists: Provide efficient, high-speed lifting and are suitable for applications where rapid lifting and precise positioning are essential. They are powered by electricity and often come with advanced control options.

Review Safety Features

Safety should always be a top priority when choosing a chain hoist. Tuffy Products chain hoists are designed with safety in mind, but it's essential to consider additional safety features, such as:

- Overload Protection: Look for hoists with overload protection mechanisms that prevent the hoist from lifting loads beyond its rated capacity.

- Emergency Stop: Electric chain hoists should have an emergency stop button for immediate cessation of operations in case of emergencies.

Check for Certification and Compliance

Ensure that the selected chain hoist complies with industry standards and regulations. Tuffy Products chain hoists are designed and manufactured to meet or exceed industry standards for safety and performance.

Maintenance and Serviceability

Consider the ease of maintenance and availability of spare parts when choosing a chain hoist. Tuffy Products provides support and service options to keep your hoist operating optimally throughout its lifespan.

Choosing the right Tuffy Products chain hoist for your application requires careful consideration of load capacity, application type, working environment, hoist type, safety features, compliance, and maintenance. By assessing your specific requirements and matching them with the features and capabilities of Tuffy Products' chain hoists, you can make an informed choice that ensures safety, efficiency, and reliability in your lifting operations.

Always consult with the experts at Browne & Co. and follow manufacturer guidelines for installation, operation, and maintenance to maximize the lifespan and performance of your chain hoist.

Author

We've compiled the latest news and technical information about our principals and our market that we hope you find informative!

Archives

June 2024

May 2024

April 2024

March 2024

February 2024

January 2024

December 2023

November 2023

October 2023

September 2023

August 2023

July 2023

June 2023

May 2023

April 2023

March 2023

February 2023

January 2023

December 2022

November 2022

October 2022

September 2022

August 2022

July 2022

June 2022

May 2022

April 2022

March 2022

February 2022

January 2022

December 2021

November 2021

October 2021

September 2021

August 2021

July 2021

June 2021

May 2021

April 2021

March 2021

February 2021

January 2021

December 2020

November 2020

October 2020

September 2020

August 2020

July 2020

June 2020

May 2020

April 2020

March 2020

February 2020

January 2020

December 2019

November 2019

October 2019

September 2019

August 2019

July 2019

June 2019

May 2019

April 2019

March 2019

February 2019

January 2019

December 2018

November 2018

October 2018

September 2018

August 2018

July 2018

June 2018

May 2018

April 2018

March 2018

February 2018

January 2018

November 2017

October 2017

September 2017

August 2017

July 2017

May 2017

March 2017

February 2017

January 2017

December 2016

November 2016

October 2016

September 2016

July 2016

June 2016

May 2016

April 2016

March 2016

February 2016

January 2016

June 2015

April 2015

March 2015

February 2015

January 2015

December 2014

October 2014

September 2014

August 2014

July 2014

June 2014

May 2014

April 2014

March 2014

February 2014

January 2014

December 2013

October 2013

September 2013

April 2013

February 2013

September 2012

February 2012

October 2011

July 2011

April 2011

January 2011

November 2010

October 2010

August 2010

April 2010

February 2010

July 2009

January 2009

July 2007

Categories

All

Abrasives

Advanced Chemical Solutions

Aerospace

AirLoc

Allen Benjamin

Alpha Tool

AlumaMill

Arno Fast Change

Arno USA

Asimeto

Award

Back Chamfer

Besly

Beveling Base Starter Kit

Bishop Lifting Products

Boneham

Boring

Boring Bars

Brian Martin

Browne & Co.

Carbide Cutting Tools

Carbide Drills

CAT40

CAT50

Catalog Download

Chain Hoists

Chamfer

Chip Thinning

Circular Saws

Clamping

Coating

Coolant

Coronovirus

Countersinks

Custom Tooling

Cutting Tools

Dapra

Dapra Vapor

Dapra Volum3

Deburring

Deep Hole Drilling

Drill Bushing

Drilling

Drill Points

Drills

Dummel

Dümmel

End Mill

Endurance Carbide

ER Colllet

ERGO

Everede

Everede Tool

Fantom

Feeler Gage

Flap Wheels

Forged Wheels

Fullerton Tool

Fury

Gage Reconditioning

Gaylee Saws

Gemtex

George Whalley

Grooving

GWS Tool Group

Haimer

Haimer USA

Harmon-i-Cut

HB Rouse

HSK

H Tolerance

Hydromat

IBC

IMTS

Industrial Supply Assoc

InovaTool

Inserts - Boring

Inserts Grooving

Inserts - Grooving

Inserts Milling

Inserts Parting

Inserts - Parting

Inserts- Turning

Intimidator

ISA Industrial Supply Assoc

ISO-9001

Jergens

Lexington Cutter

Live Center

Lubricants

Machining Cloud

Made In USA

Manufacturing

Martindale Saws

Mastercam

Material: Aluminum

Material: Bronze

Material: Cast Iron

Material: Chromium

Material: Copper

Material High Temp

Material: Inconel

Material: Plastics

Material: Steel

Material: Titanium

Measuring Tools

Memorial Day

Metals

Metalworking

Metalworking Fluid

Metrology

Mill Turn

Minimill

MRO

Multifunctional Tool

Nanotech 7000

NASA

NATC

NC Helix Drill

Nine9

North American Tool

Ohio

Peel Milling

PMTS

Polisher

Precision Brand

Promotions

Punches

QR Code

Reamers

Regal

Regal Beloit

Regal Cutting Tools

Rep Of The Year

RMT Rocky Mountain Twist

Roll Form Taps

Rouse Arno

Rouse - Arno

Safeway Sling

Sales

Sales Tools

Saw

Saw Arbors

Screw Threads

Scully-Jones

Shim Stock

Shrink FIt

Sling Inspection

Sling Safety

Slip Plate

Sowa

Spade Drills

Special Cutting Tools

Special Tools

Spot Drill

S&R Products

Stonecutter

Swiss Machining

Tap: Carbide

Tap: Carbide Insert

Tap Chamfer

Tap Definitions

Tap: Extension

Tap: Metric

Tapping

Tap: Pulley

Taps

Tap: STI

Tap: Thread Forming

Technical Support

Thread Gaging

Threading

ThreadMills

Thread Tap App

Threadwell

TIMill

Tire Mold

Tool Balancing

Tool Black

Toolholders

Tool Presetter

Tool Selection

Tool Wrap

Trochoidal Milling

Troubleshooting

Tuffy Products

Turning Tools

Valspar

Vibration Pads

Vises

V-Mac

Weldon Flat

Workholding

YG-1

RSS Feed

RSS Feed