Choosing the Right Tuffy Products Chain Hoist for Your Application: A Comprehensive Guide12/12/2023 Selecting the correct chain hoist for your specific application is crucial to ensure safety, efficiency, and optimal performance.

Tuffy Products, a one of the most reputable manufacturers of high-quality lifting and material handling equipment, offers a range of chain hoists tailored to various applications. In this guide, we' ll explore the key factors to consider when choosing the right Tuffy Products chain hoist for your needs. Determine Your Lifting Requirements The first step in selecting the correct chain hoist is to define your lifting requirements. Consider the following factors:

Understand Your Application The type of application plays a significant role in selecting the right chain hoist. Consider the following applications and their specific needs:

Consider Your Working Environment The environment in which the chain hoist will operate is essential for making the right choice:

Evaluate Chain Hoist Types Tuffy Products offers different types of chain hoists, including manual chain hoists and electric chain hoists. Consider which type best suits your needs:

Review Safety Features Safety should always be a top priority when choosing a chain hoist. Tuffy Products chain hoists are designed with safety in mind, but it's essential to consider additional safety features, such as:

Check for Certification and Compliance Ensure that the selected chain hoist complies with industry standards and regulations. Tuffy Products chain hoists are designed and manufactured to meet or exceed industry standards for safety and performance. Maintenance and Serviceability Consider the ease of maintenance and availability of spare parts when choosing a chain hoist. Tuffy Products provides support and service options to keep your hoist operating optimally throughout its lifespan. Choosing the right Tuffy Products chain hoist for your application requires careful consideration of load capacity, application type, working environment, hoist type, safety features, compliance, and maintenance. By assessing your specific requirements and matching them with the features and capabilities of Tuffy Products' chain hoists, you can make an informed choice that ensures safety, efficiency, and reliability in your lifting operations. Always consult with the experts at Browne & Co. and follow manufacturer guidelines for installation, operation, and maintenance to maximize the lifespan and performance of your chain hoist.

0 Comments

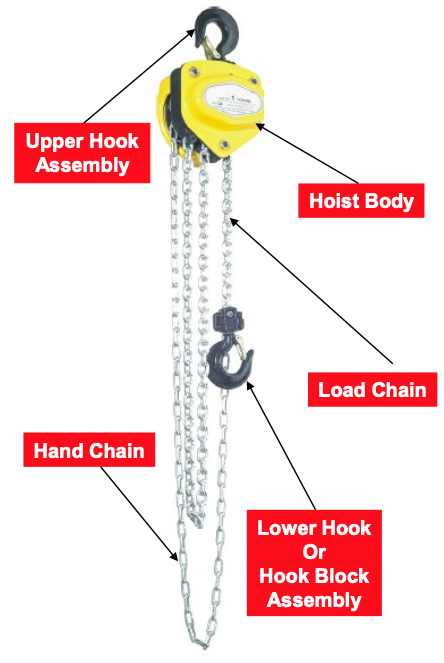

written and edited by Bernard Martin A hoist is a machine that can be used for lifting and lowering heavy loads In most applications a hoist is usually suspended overhead by means of a hook or connected to a trolley. Hoists can be powered by hand, electricity, or air and can be supplied in various shapes and configurations. A hand chain operated hoist, being a force multiplier, gives a person the ability to lift large / heavy loads with a small amount of force by using mechanical advantage. The lifting or lowering operation takes place by pulling on one side or the other of the hand chain which is endless. Hand chain hoists are less expensive than powered hoists but they require the physical effort of pulling the hand chain to lift the load. Chain hoists are great options to replace the manual lifting process in assembly lines and other material handling areas. Manual chain hoists typically operate with two chain loops, the hand chain and lifting chain. The hand chain wraps around a wheel that supports the lifting mechanism by pulling. The lifting chain is used to lift and lower the load by maneuvering the hand chain. This type of hoist system can be used in manufacturing facilities, construction sites, auto shops and warehouses. In industrial applications, hand chain hoists are most often used as an in-plant tool for periodic maintenance applications. A typical use might be for lifting pumps, generators, valves, pipe or other heavy equipment.

Chain Hoist Terms & How to Select the Best Chain Hoist for Your Needs There are several things you should consider when selecting a manual chain hoist. Manual hoists have the advantage of being compact and light when compared to electric hoists. Here's some things to think about when selecting the best chain hoist for your applications.

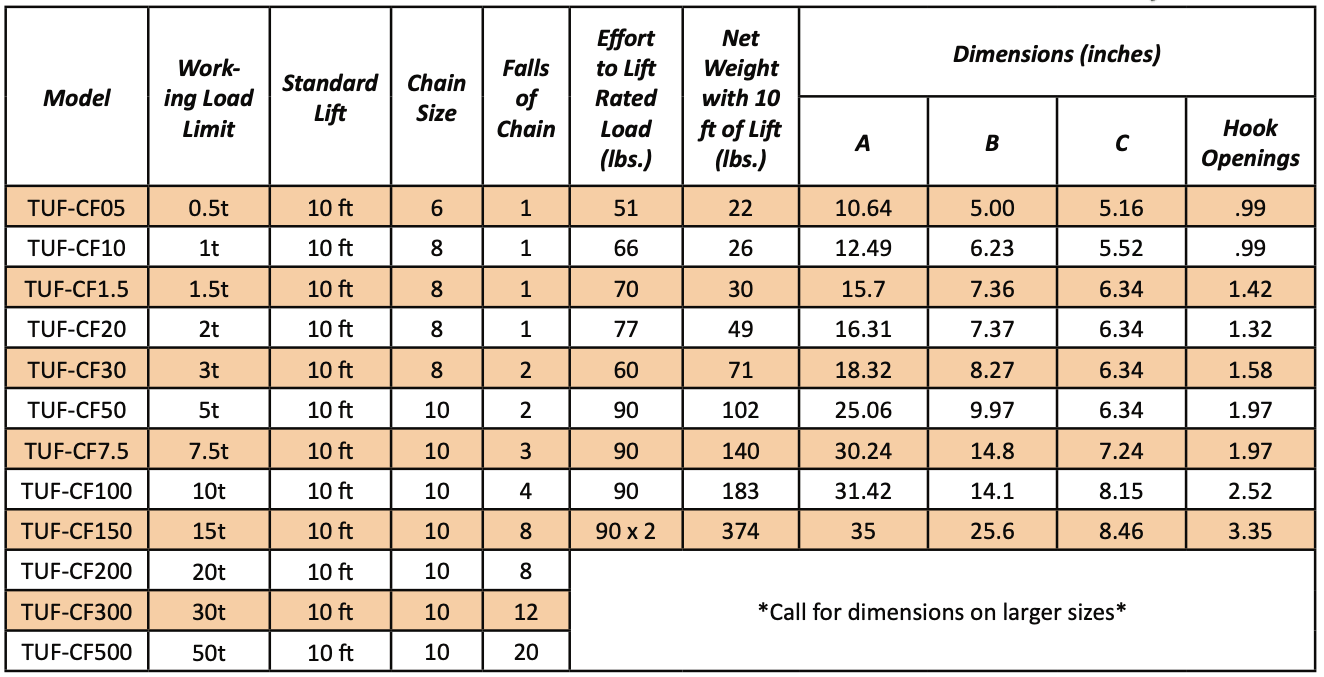

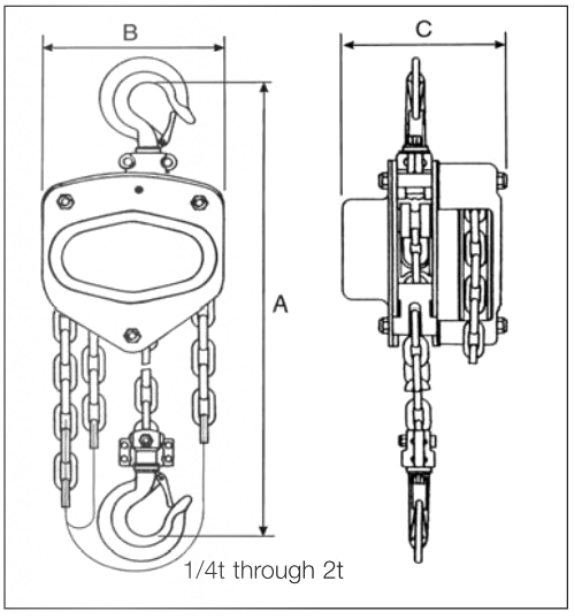

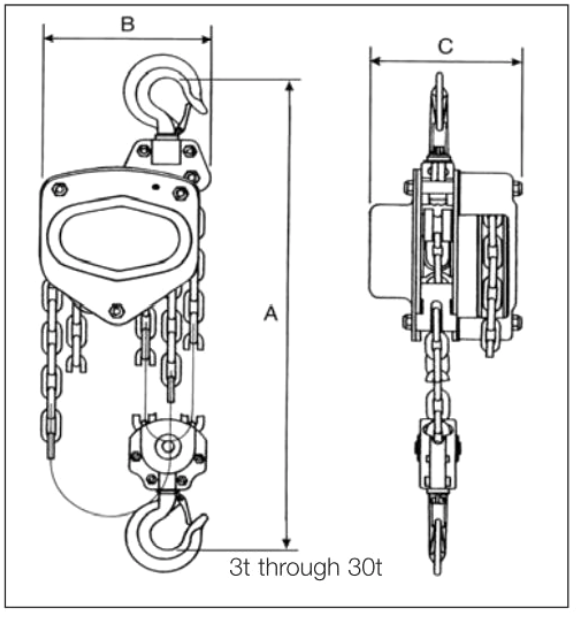

FALL OF CHAIN This is the number of chains that attach to the lifting chain hook. Additional Falls of chain is It's what enables Tuffy to use a 10mm chain for up 50 tons of lift. By standardizing on a chain size of 10mm it's easier to stock replacement parts and also to keep the overall costs down SUSPENSION The way you hang the manual chain hoist referred to as its suspension. The two most common types of suspension are the hook suspension and lug suspension. Most hoists allow for a lug suspension. It is particularly useful in situations where headroom for hoist operation is limited or insufficient. HEADROOM This describes one of the dimensions of a hoist. This dimension is the distance between the bearing surfaces of the upper and lower hook when the lower hook is raised to its highest point. (or the minimum distance between the hooks) Headroom is depicted in the chart below by dimension "A" OTHER FACTORS TO CONSIDER Other factors include the height of the hook point: where the chain hoist will be mounted, and type of operator interfaces, such as hand chains. Do you have low headroom? Will you be using this on an A-frame gantry? Then dimension A in the below chart is going to be important to you. If you are mounting from the ceiling you will need to know if it is an I-Beam or H-beam and is it the beam flat or tapered? Explosion proof environments or clean room environments each have some specialized requirements that we can help you with but, for now, keep in mind that each beam has different applications and is a topic unto itself. TUFFY CHAIN HOIST FEATURES:

NOTE: Please specify chain length required when ordering, by adding a -5, -10, -15, -20 to the end of model number. As shown above in the chart, the standard is a 10 ft. lift. Below you can get more information in the Tuffy Hoist Catalog and also information on our selection of beam clamps, plain beam trolleys, and geared beam trolleys to attach your chain hoist to a beam. In January of this year we welcomed a new member to our Browne & Co. sales team and with manufacturing companies opening up again, it's about time we introduce you to Jeff Terrace!

Just before joining Browne & Co in January 2019, Jeff worked at Hoffmann Group, a German cutting tool, hand tool, workstation and storage solutions manufacturer. Jeff has been working as an InovaTool representative since February of 2019 and recently joined Browne & Company at the beginning of 2020 as our Cutting Tool Specialist. Please send Jeff and email or give him a call to introduce yourself or pick his brain about an application question. In industry, hand chain and lever operated hoists are most often used as an in-plant tool for periodic maintenance applications. A typical use might be for lifting pumps, generators, valves, pipe or other heavy equipment. Whether a hoist is used in construction, maintenance, machine shops or automotive garages, hundreds of applications exist for a manual chain hoist and many thousands are sold every year. One of the largest lifting rental yards in the United States (TX) has standardized on Tuffy Hoists for their rental fleet - If they can take the rigors and abuse of rental, they can certainly stand up to anything your shop can throw at them!

Please call or email Browne & Company for your closest authorized Tuffy Hoist distributor

440-463-3970 [email protected]

How to Inspect Synthetic Web Slings All of our synthetic web products are designed for long life under punishing conditions, but they will eventually wear out after extended use. The key is knowing when to replace them, and that’s why it’s very important to inspect your slings on a regular basis. We’ve developed an inspection program based on the procedure outlined in ANSI B30.9 that will make the most of your investment. It’s based on four sound beliefs:

How Often to Inspect Slings The frequency of inspection depends on three important factors:

When to Replace Slings

|

AuthorWe've compiled the latest news and technical information about our principals and our market that we hope you find informative! Archives

June 2024

Categories

All

|

|

Browne & Co., Inc.

9605 Tanager Drive Chardon, Ohio 44024 |

© 2024 Browne & Co., Inc. All Rights Reserved

web design by Rapid Production Marketing |

RSS Feed

RSS Feed