|

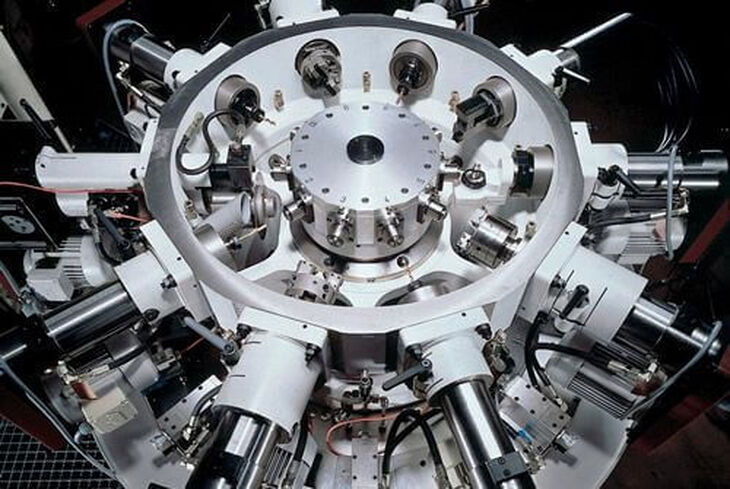

Advanced Chemical Solutions introduces FormKut Light with a proprietary blend of additives specifically tailored to Hydromat Rotary Transfer machining, providing faster cutting speeds, greater feed rates and higher part quality with superior surface finishes.

Our Formkut light oil formulation is designed for medium to moderately difficult machining on steel, stainless steel, and nonferrous materials. A transparent chlorinated cutting oil allows operators easy visual references to the tooling. Formkut light is an economical product that is appreciated by machinists for its lack of odor and non-irritating properties. Please contact Browne & Company for your closest, authorized, Advanced Chemical Solutions distributor.

1 Comment

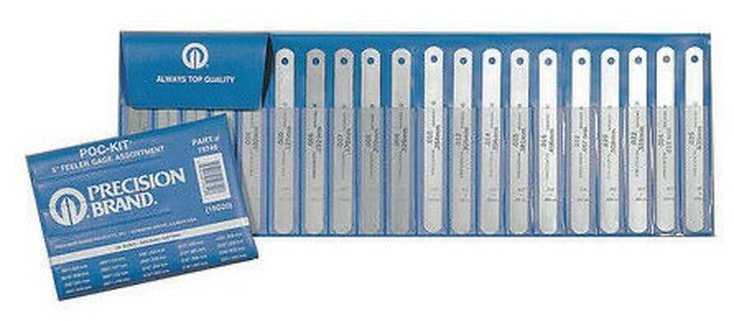

Precision Brand® Thickness Feeler Gages are made from high carbon (C1095), close grain, spring steel. The high carbon content ensures that the material does not compress, producing consistent accuracy, which is the most important aspect of this precision measuring tool. Is Feeler Gage available in metric thicknesses? Yes, Precision Brand also offers a “true metric” size Steel Feeler Gage. It is made from material specifically manufactured in Europe to precise millimeter thicknesses. Precision Brand Steel Metric Feeler Gage enjoys the same exacting tolerances as its decimal counterpart. Is Feeler Gage available in materials other than steel? Yes, Precision Brand offers various types of feeler/thickness gage material for numerous manufacturing situations.

You can receive a brochure from Precision Brand Products, Inc. which outlines all the types of feeler/thickness gages offered, just by contacting the customer service department at (630) 969-7200 or e-mail us. How is Feeler Gage packaged? Precision Brand Products, Inc. offers a variety of packaging options for the feeler/thickness gage products, depending upon the material desired. Precision Brand® offers 5 inch and 12 inch blades, 25 foot coils, fan blade assortments, poc-kit® assortments and bulk material. You need to refer to the Precision Brand catalog, price book, feeler gage brochure or contact the customer service department at (630) 969-7200 or e-mail us for specific product offerings.

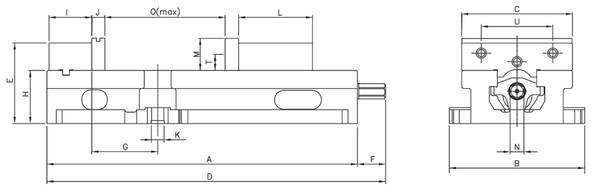

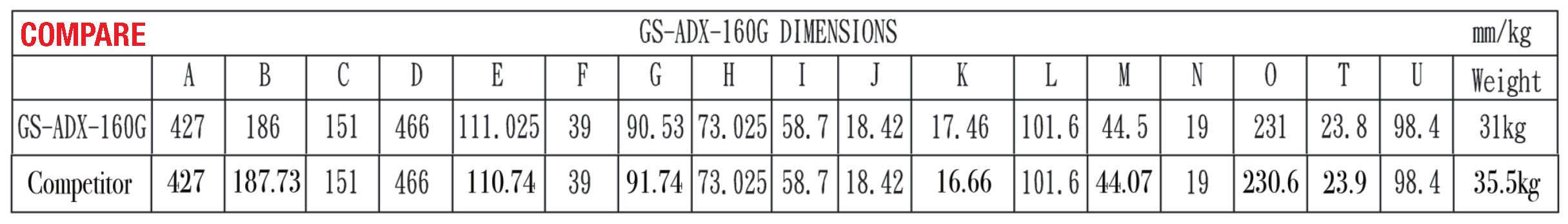

Code# 327320 Regualr Price: $589.50 $475.00 Please contact Browne & Comapny for closest authorized Sowa GS distributor

Fullerton Tool Company now supplies, stocks, and supports InovaTools' products!

Their strategic partnership with InovaTools allows Fullterton to expand thier product offering by selling, stocking, and supporting Inovatools' coolant fed, deep hole drills, micro drills, modular tools, diamond coated end mills, and die & mold end mills. Fullerton is Now Offering InovaTools:

If you deal with exotic alloys like Inconel, titanium, Hastelloy, etc., this article is written especially for you. Wise operators always select the correct tool for the job, avoiding the problems others face when they try to apply a general-purpose tool to a unique situation. In this article, we give you the information you need to select the proper tools for machining exotics. It will make your shop stand out from the competition since you will produce better results at a reduced cost. The Hard Stuff Exotic alloys are specifically designed for high-temperature applications (think aerospace), performance in corrosive environments (think underground), or to have the highest available strength to weight ratios (think earth-moving applications). The machinability of these materials is NOT the first consideration. As much as it would be nice from the machinist’s viewpoint to have an aluminum firewall in a helicopter, as the pilot or passenger you want a material that is strong and heat retardant.

The Answer

One day a new job order comes in and you are faced with threading these kinds of alloys. What’s an operator to do? Fortunately for you, North American Tool manufactures application-specific thread mills right here in the USA. These tools are made from solid carbide and have been specially designed with exotic materials in mind. The results are longer more consistent tool life and the elimination of scrap due to tap failures in your parts. Uniquely Crafted North American Tool thread mills for exotic alloys are designed with only three teeth. This places less stress on the tool than a conventional thread mill with six, eight, or ten teeth engaged in the workpiece at the same time. Carbide thread mills nickel-based alloys are also made with left-hand helix and left hand-cut, which permit an operator to run from the top of the hole to the bottom and climb mill the threads. This will create a right-hand thread on the part. The threads are milled, rather than cut, typically producing a better quality thread in the part. The thread mills are coated with AlCrN to give them greater heat and wear resistance in the high heat, higher abrasive applications that typically confront an operator when machining exotic alloys. Exotic Material Experts As well as thread mills, we are the industry leader in designing and manufacturing special taps for exotic materials as well. Thread mills are a good alternative tool to the special taps we design every day provided of course, you have a 3-axis CNC capable of the interpolation tool path needed for thread mills. If you are working with exotic materials and need a thread mill or special tap, please contact us for a quote. We’d be happy to help. |

AuthorWe've compiled the latest news and technical information about our principals and our market that we hope you find informative! Archives

June 2024

Categories

All

|

|

Browne & Co., Inc.

9605 Tanager Drive Chardon, Ohio 44024 |

© 2024 Browne & Co., Inc. All Rights Reserved

web design by Rapid Production Marketing |

RSS Feed

RSS Feed