|

Explore the role of end mill components in machining various materials with our guide on selecting the right features based on ISO 513 classifications, enhancing machining efficiency and tool life. The components of an end mill play a crucial role in determining its performance and suitability for machining different materials. The best way to understand the importance of different features of an end mill is start with the material you are cutting. Just like a butter knife is not good for cutting steak, selecting features for an end mill is very dependent upon the material you're cutting. Let's start with some background information. The ISO 513 is a standard that classifies materials based on their machinability and provides guidelines for cutting speeds, feeds, and tool selection. ISO 513 provides a classification system for the machinability of materials, organizing them into categories based on the characteristics which influence their behavior during machining processes. The main categories include:

Now, let's dig into the details. Below you'll find the key components of an end mill and how they relate to machining different ISO 513 material types:

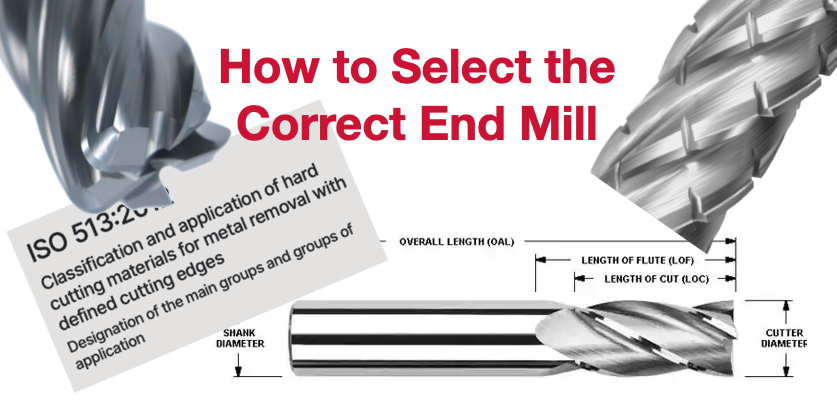

End Mill Anatomy OverviewThe anatomy of an end mill refers to its various components and features, each of which plays a critical role in its cutting performance. End mills are rotary cutting tools used in milling operations to remove material from a workpiece.

Here's a breakdown of the key parts of an end mill:

0 Comments

Leave a Reply. |

AuthorWe've compiled the latest news and technical information about our principals and our market that we hope you find informative! Archives

June 2024

Categories

All

|

|

Browne & Co., Inc.

9605 Tanager Drive Chardon, Ohio 44024 |

© 2024 Browne & Co., Inc. All Rights Reserved

web design by Rapid Production Marketing |

RSS Feed

RSS Feed