Haimer USA, LLC

HAIMER is a family run company located in Igenhausen, Bavaria near Augsburg, Germany. Haimer USA's 30,000 sq ft Headquarters is located in the Chicago suburb of Villa Park. HAIMER designs, produces and sells innovative, high precision products for metalcutting as well as for the automotive, aerospace, energy, rail and general machining industries. HAIMER is best know for it's large offering of rotary toolholders in all popular interfaces and lengths, as well as shrinking and balancing machines. HAIMER is a well respected brand for their 3-D Sensors and tool presetting machines.

|

134 E. Hill Street

Villa Park IL 60181 Phone: +1-630-833-1500 Fax: +1-630-833-1507 Email: [email protected] |

Haimer Steep Taper & HSK Toolholders

|

|

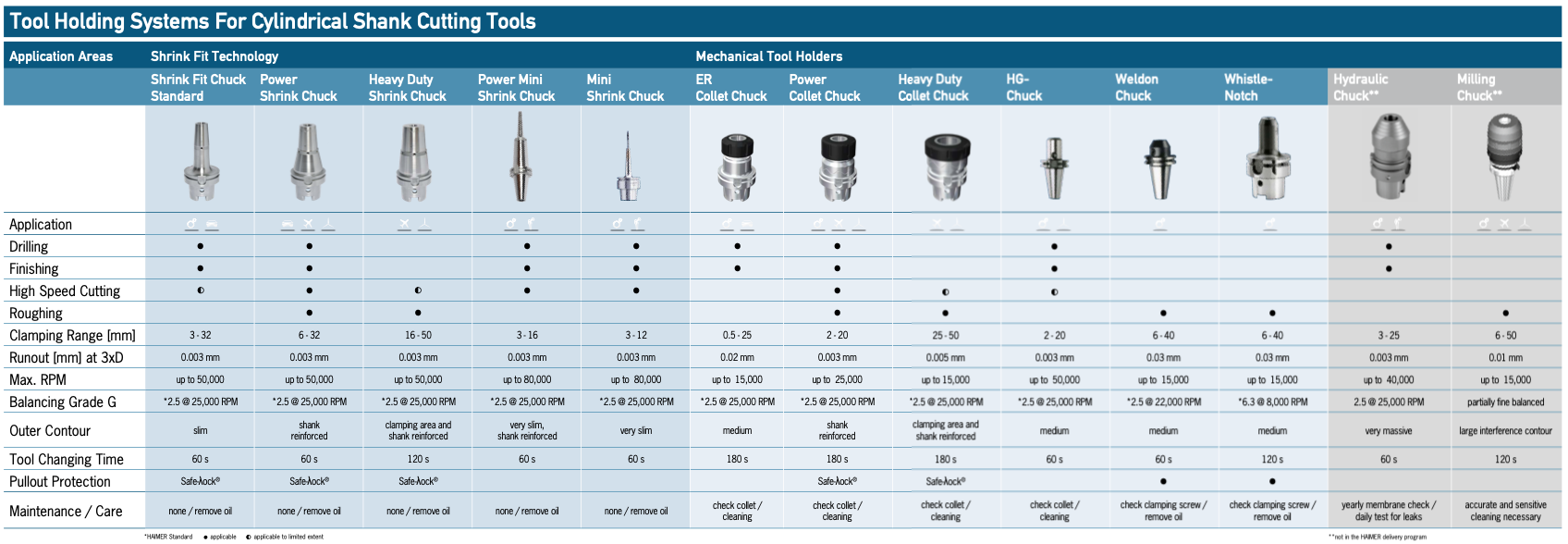

With the HAIMER tool holders, HAIMER offers the right solution and tool clamping technology for all specific requirements. Each year Haimer invests approximately 10 percent of their budget into research and development.

Haimer makes CAT 40, CAT 50, BT 30 BT 40, BT 50, as well as all styles of Hollow taper shank holders: DIN 69893 HSK-A, HSK-E, HSK-F. HAIMER offers a broad range of holder accessories from its own manufacturing. Shrinking extensions, tool clamping devices, reduction sleeves, Collets ER & Power Collets, pull studs. |

Shrink Fit Technology - Power Clamp

|

For years, HAIMER has been leading in the development of inductive shrink technology for tool holders. Many patents, mainly in the area of inductive coils, are visible proof for innovation and progress.

The patented coil technology in conjunction with the intelligent power electronics form the core of HAIMER shrink fit technology. Perfectly coordinated assembly groups and electronic components make sure that only the clamping area of the chuck is heated in the shrinking process. This reduces the shrinking and cooling cycle to a minimum. |

HAIMER Microset Presetting Technology

|

The efficient tool presetting equipment from HAIMER Microset optimizes your machining processes from the ground up.

Improve your tool life, achieve better surface finishes and boost overall process reliability in your production.

|

Modular Balancing Technology - Tool Dynamic Balancing Machines

The spindle speed of CNC machine tools have increased on a continuous basis in the last few years.

|

The increases have raised the demand for balanced toolholders, because the higher spindle speeds make the effects of imbalance increasingly more noticeable. The consequences imbalance are vibrations, bad surface finish and shorter tool life.

With the Tool Dynamic balancing machine series, HAIMER offers a comprehensive solution for the balancing of tool holders, grinding wheels and big rotors with diameters up to 800 mm. Starting from the table and complementary machine TD 1002 to the automatic balancing machine TD 2010 Automatic, HAIMER has for every need the suitable balancing machine. |

|

|

|