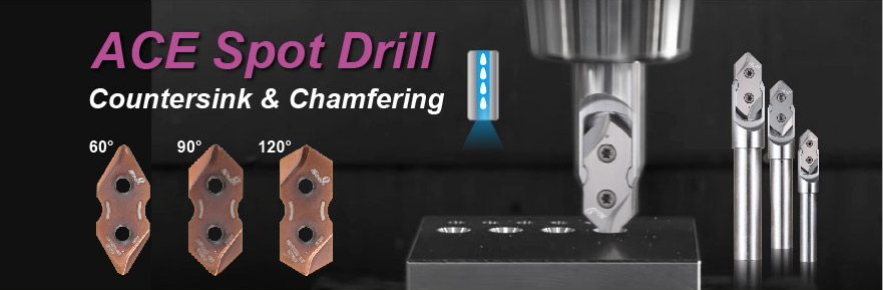

The Ace High Performance spot drill sets a new standard for precision, durability, and speed, thanks to its state-of-the-art design and materials. Engineered for unparalleled performance, this drill offers significant advantages, including reduced machining time and extended tool life, making it a valuable asset for manufacturers seeking to optimize their operations.

The Ace High Performance spot drill's unique features, including its advanced coating technology and geometric design, together enhance cutting efficiency and accuracy across a wide range of materials. Early adopters praise its performance, noting measurable improvements in productivity and cost savings.

Suitable for a diverse array of applications, from aerospace to automotive manufacturing, the Ace High Performance spot drill versatility and technical superiority make it a must-have tool for any machine shop requiring precise and efficient material removal.

The drill is now available for purchase through Browne & Company's distribution network, with special introductory offers designed to provide exceptional value to early customers. Interested buyers are encouraged to act quickly to take advantage of these limited-time promotions.

Check out the flyer below - they are offering two 90° MiniSets at over 1/2 price! Check out the flyer below for the promotion.

Contact us for authorized distributor choices.

RSS Feed

RSS Feed