|

Since 1957, General Die Casters has worked closely with their customers, to design, manufacture, and deliver the custom die castings they demand. In March 2010 they opened their new 90,000 square foot expansion casting foundry in Twinsburg, OH. service the Appliance, Automotive, Commercial, Computers & Peripherals, Electrical, Industrial, Lawn & Garden, Recreational and Transportation Industries.

Advanced Chemical Solutions was invited to discuss coolants that would not only perform well but also not have an odor, foam or cause dermatitis. Mark Pierson from ACS with closely with Keith Kish, the Director of Manufacturing Engineering at General Die Casters. According to Keith, "I was looking for an economical coolant that would not stink, foam or have skin issues for our employees. Advanced Chemical Solutions evaluated our facility and provided Nano Tech 6800 for testing." General Die Casters has a good number of CNC machines from Brother, Mori Seiki, Chiron, Takisowa, DMC, Kitako, and a good number Haas machines. Taking good care of their employees is important to the the company. Recently, several employees celebrated 20 years of service at the company. One of them was Anderson Grant, the first shift operator “In most companies, it’s very rare to see employees who reach 20 years of employment. At General Die Casters, it is common to see people reach 35 years at the company. We have a work culture where there is mutual respect and support of one another. When one of us succeeds, we all succeed”, says Anderson. Having odor free coolant that didn't cause dermatitis is part of keeping employee morale high. According to Keith, "Nano Tech 6800 is absolutely the best coolant we have ever used in our machines. No Monday morning odor, coolant stays fresh and clean." But what about tool life? Keith tells us "This coolant has dramatically improved our work environment helping to keep our machines cleaner and improving our tool life."

1 Comment

The Never before have we experienced pricing volatility in metalworking fluids like today

These price increases come with long lead times and overall shortages THAT’S THE BAD NEWS….. THE GOOD NEWS IS You can overcome this with Advanced Chemical Solutions We forecasted this 8-10 months ago.

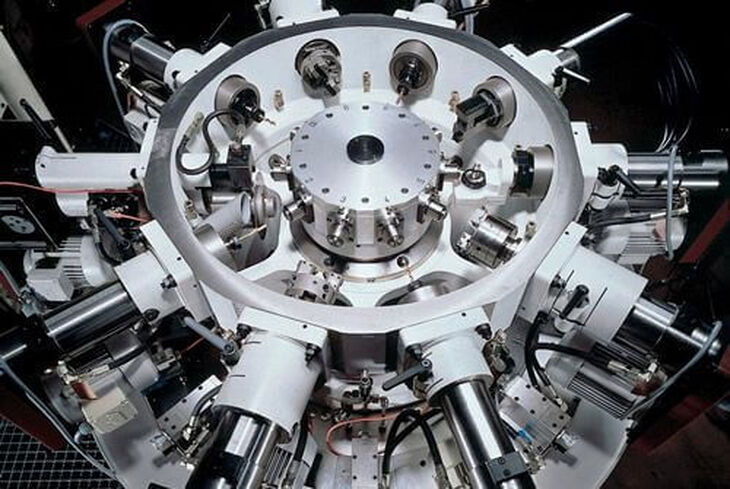

These changes were in preparation for the current market We can bring the SOLUTION to you, today… Quality, Price and Availability Please give Advanced Chemical Solutions an opportunity to quote your coolants and oils today Visit Browne & Company in Booth 2088 This year at PMTS, our Booth # 2088 will be featuring Advanced Chemical Solutions, Fullerton Tool Company, and Everede Tool Company. Understanding the relationship between cutting tools and metalworking fluids provides us with an advantage you will not find with any other exhibitor, an advantage that you can put to work for you. Friendly members of our team will be ready to answer any questions you might have. To check out Booth 2088 in person, be sure to register for PMTS below! Hope to see you there! Advanced Chemical Solutions introduces FormKut Light with a proprietary blend of additives specifically tailored to Hydromat Rotary Transfer machining, providing faster cutting speeds, greater feed rates and higher part quality with superior surface finishes.

Our Formkut light oil formulation is designed for medium to moderately difficult machining on steel, stainless steel, and nonferrous materials. A transparent chlorinated cutting oil allows operators easy visual references to the tooling. Formkut light is an economical product that is appreciated by machinists for its lack of odor and non-irritating properties. Please contact Browne & Company for your closest, authorized, Advanced Chemical Solutions distributor.  Advanced Chemical Solutions understands the challenge of lube oil leakage from the head stock system into the cutting oil, it's this intermingling of oils that can lead to premature tool failure, staining of metals, excessive smoking and an overall degeneration of your cutting oil.

Advanced Chemical Solutions has formulated their multi spindle dual purpose oil to eliminate these issues. The use of our dual purpose oil as both lube oil and cutting oil assures excellent machinability while minimizing the likelihood of staining on the sensitive metals used in gear and hydraulic systems. After extensive testing we have found:

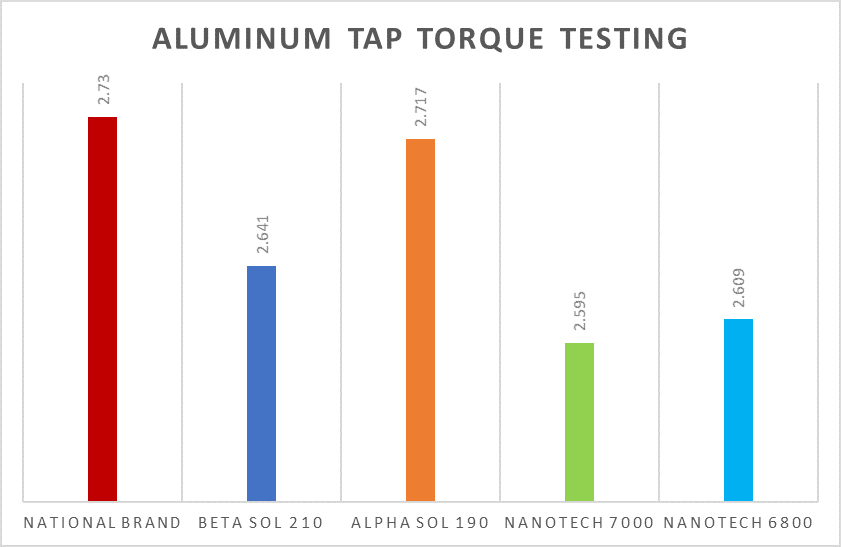

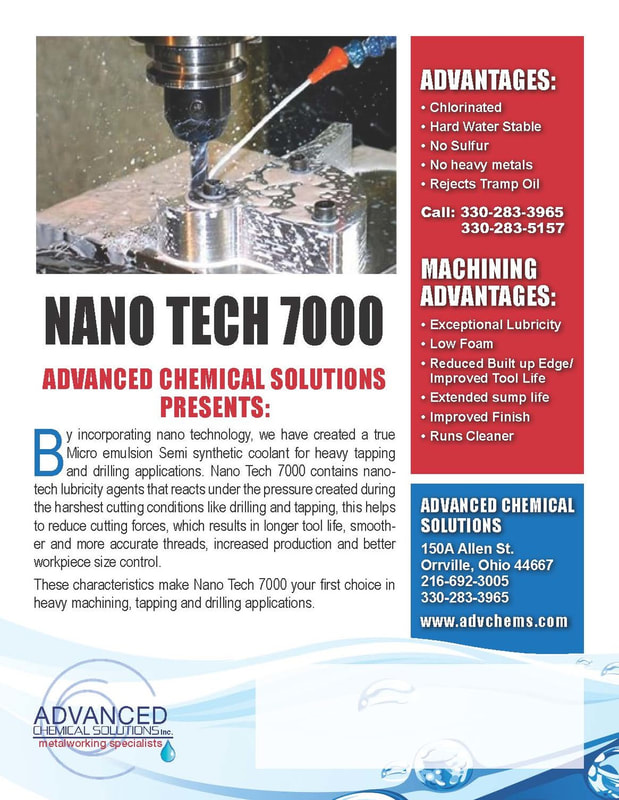

Address this age old problem today! Contact us for your nearest authorized distributor of Advanced Chemical Solutions: 440-463-3970 * [email protected] We are often asked by end-users for a single coolant that’s effective in all materials and all applications. The family of Nano Tech products eliminates the need for multiple types of coolants.

Using innovative additives, Nano Tech products can be used on Aluminum with no fear of staining to high nickel alloys, providing excellent tool life. Engineered to provide maximum lubrication, Nano Tech products also provide maximum cooling, extending tool life in milling, drilling and turning applications. Advanced Chemical Solutions is best known for our customized fluids that help impart the best quality finish and tool life for a specific material or cutting operation, from this Nano Tech products where formed. Using Nano Tech will provide end-users a multioperation fluid to product high quality parts without sacrificing material-based performance. Progressive companies are always looking for innovative products that can increase production, lower production cost and even improve finish products. These same companies often overlook their current metalworking fluids,

It's common to hear "we have used brand X for years with no problems." The problem is lost opportunity cost. At Advanced Chemical Solutions, we are driven by innovation and improvement. Using today's technologies, ACS has created more advanced metalworking fluids. We focus on providing a healthier, cleaner running product that offers a higher operator acceptance. Using the latest nano technology, allows us to make products that will improve cycle time, improve tool life, improve part tolerance and improve surface finish. The attributes of these products will not only positively impacting the quality of your finish parts, but will positively impact your employees as well.

Lost opportunity cost, Don't fall victim to "we have used brand X for years", Metalworking fluids are just like cutting tools: they continue to evolve and offer new innovations. In metalworking fluids these innovations come in the form of new base materials and additives. Want to learn how these products can impact your business, get more details on Advanced Chemical Solutions webpage. |

AuthorWe've compiled the latest news and technical information about our principals and our market that we hope you find informative! Archives

June 2024

Categories

All

|

|

Browne & Co., Inc.

9605 Tanager Drive Chardon, Ohio 44024 |

© 2024 Browne & Co., Inc. All Rights Reserved

web design by Rapid Production Marketing |

RSS Feed

RSS Feed