|

Recently we had an application question at North American Tool. A customer had opened up the drilled hole to 55 percent of thread in hopes of reducing wear and increasing tool life. Instead, it lead to the cut tap breaking at the first full thread of engagement. That prompted a engineering discussion and is the basis of this technical article to address this very common misperception. If a tap doesn’t create the hole, why is the hole size so important?

This leaves the good machinist to select a drill that is more or less than 75%. If 75% is good, then a higher number is better, right? WRONG (in many cases). On page 115 of the current North American Tool catalog a range for percentage of threads from 50% to 85%, with the recommended range between 65% and 75%. This guideline range to use is a reflection of several factors:

In higher tensile steels, larger hole sizes (less percentage of thread) may work better to reduce torque in tapping. When using oversize hole diameters, the tap should also have an oversize chamfer point diameter so all threads in chamfer are cutting and not just dropping in a hole. Such was the case with the application porblem. As was stated above the operator thought that by increasing the drill diameter size would lead to better tool life. Instead, because the diameter was of the hole was so large the cut tap did not engage the threads along the chamfer length and instead engaged at the first full thread at the end of the chamfer. The caused premature wear and stress on the that thread in the flutes and eventually to catastrophic failure. The solution was a modified tap from North American Tool. Summary: You've got to use the correct tap for the application! At the end of the day, taps are made to very strict tolerances, often much more so than the piece parts they are called on to machine, and the first place one might want to find blame is with the tap.

Why? Because;

What if one manufacturer makes a tap that works and another one made by a different company doesn’t work at all? In all likelihood, the “general purpose” of one is closer to the correct geometry for the application. One might get a completely different result if another material were being machined. Therefore it is always best to order a tap for the specific application.

1 Comment

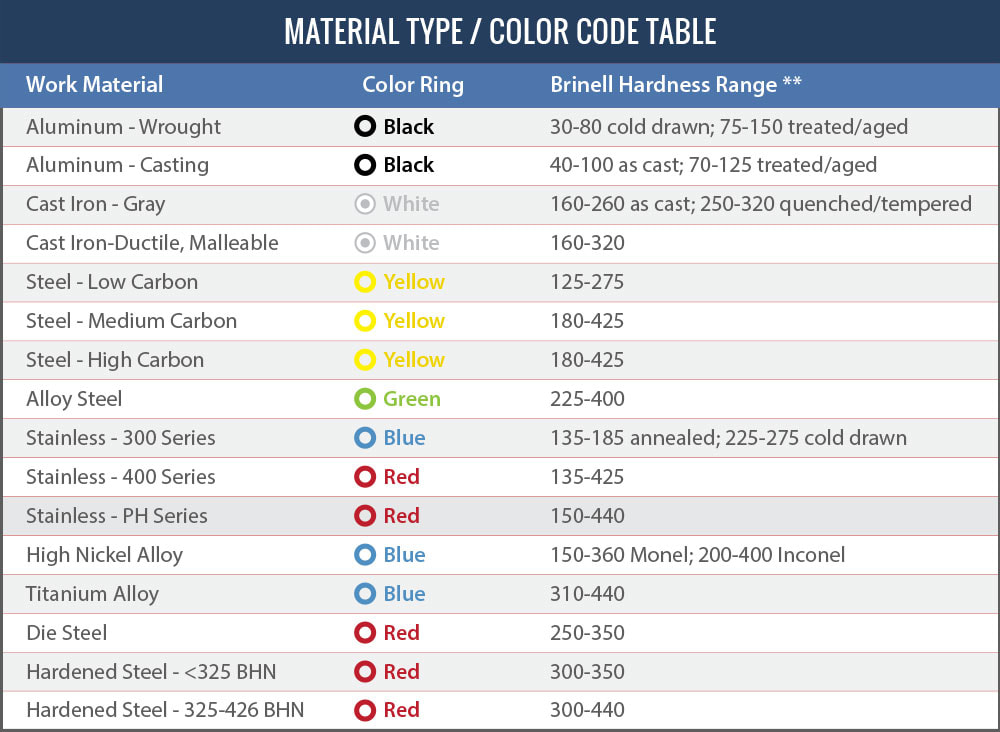

Allen Benjamin color codes HSSE taps to simplify the selection of the right tap for specific materials. Each of the six color-ring taps are manufactured with application-specific design criteria based on characteristics and hardness range of various part materials. The table below illustrates which color ring tap is best suited to the material being threaded. *NOTE: For material or material group not shown (such as No Lead Brass), please consult Customer Service here. ** BHN hardness range may vary depending on steel/workpiece condition. SURFACE TREATMENT ABBREVIATIONS

North American Tool is proud to announce the release of Thread Tap App Cloud®, which is available at http://tapapp.natool.com Thread Tap App Cloud® replaces the Desktop version and offers a completely updated look and feel, powerful new features, and does not require any software installation.

Thread Tap App® is also available for the iPad and Android Tablets. The companion standalone Tap Hole Size Calculator App®, which is available for iPhone and Android phones, is a 3-in-one calculator for recommended tap hole size, an easy to use trigonometry calculator, and a standard calculator for quick calculations.

All North American Tool Apps can be downloaded free of charge. ABOUT NORTH AMERICAN TOOL: North American Tool is an ISO 9001:2008 registered manufacturer of premium cutting tools – special taps, dies, and gages – for the industrial marketplace—aerospace, medical, automotive, energy, agriculture, general manufacturing, and more. For more information about North American Tool Corporation, visit the website at www.natool.com. |

AuthorWe've compiled the latest news and technical information about our principals and our market that we hope you find informative! Archives

June 2024

Categories

All

|

|

Browne & Co., Inc.

9605 Tanager Drive Chardon, Ohio 44024 |

© 2024 Browne & Co., Inc. All Rights Reserved

web design by Rapid Production Marketing |

RSS Feed

RSS Feed