|

New Product !

This high accuracy vise has been specially designed to prevent workpiece lift and is ideally suited for single station vise applications in CNC machining centers. On Vertical Machine Centers it has 2 operating positions: Upright & Lay Down. On Horizontal Machine Centers it has one operating position: Horizontal. Only $837 while supplies last Please call for your nearest authorized Sowa distributor (440) 463-3970

0 Comments

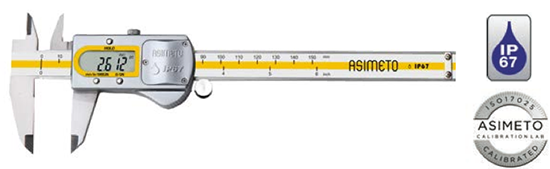

Recalibrate Your Expectations We have gone back and rebuilt the Top 40 flyer from scratch. Many previous items have been removed and others added in so that only the most popular items remain. In keeping with the new Asimeto North America Stock Program we have made sure that every item in this new Recalibrated Promo is in stock in quantity in Ohio. Please call Browne & Company 440-463-3970 for your closest authorized Asimeto distributor. RECALIBRATE YOUR EXPECTATIONS Downtime, poor quality, and rising costs are a few variables unacceptable in any manufacturing environment and you need to trust that your suppliers have your back. At Sowa Tool, they take this responsibility very seriously and why they are really proud to introduce their new Asimeto North American Catalog. With your feedback, they have identified a mix of the most popular precision metrology tools used in aerospace, automotive, energy, and general manufacturing.  Every Asimeto tool that Sowa Tool supply's comes with an ISO 17025 calibration certificate so our customers can be confident that the measuring accuracy conforms to national specifications. Coupled with Asimeto’s strong quality promise, thye’ve lowered prices across hundreds of items to make sure our customers are receiving the highest possible value for their dollar. Additionally, thye’ve made significant investments in local inventory to ensure these products are consistently and reliably in stock to support our customers all across North America. In fact, the goal at Sowa Tool is to achieve 100% service level on every item in this catalog. While reaching this goal may sound difficult earning and keeping your trust as a valued supplier is our number one priority. We know you have a choice on where to buy your favorite brands. We thank you for choosing Sowa Tooll and Asimeto. Sowa Tool will turn 60 next year and in all that time we have obviously spent a significant amount of effort developing what we consider the "complete package" of spindle tooling and supplies.

CAT40 and CAT50 starter packages, including trolley, as well as CAT40 and CAT50 ER16 Collet Chuck 4 packs, including collet sets on sale now through June 30, 2019.

*GS Holders 100% Forged Construction *Certified Balanced up to 30,000 RPM *DIN Coolant Through The Flange Standard *Best Added Value on Standard Holders In The Market! Please call or email Browne & Company for your closest GS authorized distributor 440-463-3970 or [email protected]  GS Shrink Fit Clearance We've launched our Spring Sales Quarterly and it's all about our GS Shrink Fit Tooling. All in-stock Shrink Fit Tooling has been reduced 40% off regular list price. The interference fit between the ID of the tool holder and cutting tool shank forms the seal, preventing the coolant from flowing anywhere else except through the coolant grooves. The use of Heat Shrink Tooling allows for greater speeds and feeds, better finishes, increased tool life, and increased productivity due to its High Speed Machining capability and simplicity of use. Fullerton Tool's 3200 General Purpose end mills are NOW AVAILABLE with FC20 coating.

The Fullerton Tool 3200 FC20 end mills perform similar to high performance tooling but at a general purpose price. They are a great value - providing versatile tooling solutions that produces increased productivity for a fraction of the cost. Give them a try! 3200 FC20 End Mills:

If you have a shop (or a customer) that machines aluminum and aluminum alloys as its go-to substrate, why are you selling/buying general purpose tools? You are working with the most popular-to-machine material. How does your company stand out from your competitors who machine aluminum? Isn’t the advantage of aluminum that it is already free-machining and more desirable to work with in the first place? Isn’t it likely your competitors have reached the same conclusion? If you are using general purpose tools, you are likely getting similar results to your competition. Here’s a suggestion on how to make a competitive advantage. Application specific tools like the TMAL series from North American Tool allow you to optimize the tool you use for the aluminum you machine. Take advantage of a more aggressive geometry, a micro-grain carbide substrate and the ZrN coating to give you a performance advantage over general purpose tools. What makes these North American Tools application specific and how are they different?

North American Tool's Thread Mill Brochure Check out our Thread Mill Brochure below and find the tool that was created for your job.

Keep in mind all diameters specified are just the shank the pitches are ground on. Your hole size should be large enough to allow for the circular interpolation to take place on your CNC equipment. It is generally recommended (call it a guideline, not a rule) that the tool diameter should not exceed 80% of the hole size for which it is used. We offer programming information on page 16 and troubleshooting info on page 17 for your convenience. |

AuthorWe've compiled the latest news and technical information about our principals and our market that we hope you find informative! Archives

June 2024

Categories

All

|

|

Browne & Co., Inc.

9605 Tanager Drive Chardon, Ohio 44024 |

© 2024 Browne & Co., Inc. All Rights Reserved

web design by Rapid Production Marketing |

RSS Feed

RSS Feed