|

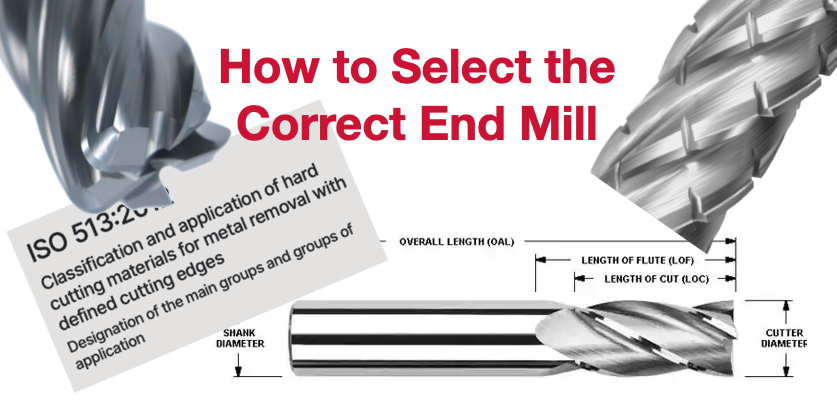

Explore the role of end mill components in machining various materials with our guide on selecting the right features based on ISO 513 classifications, enhancing machining efficiency and tool life. The components of an end mill play a crucial role in determining its performance and suitability for machining different materials. The best way to understand the importance of different features of an end mill is start with the material you are cutting. Just like a butter knife is not good for cutting steak, selecting features for an end mill is very dependent upon the material you're cutting. Let's start with some background information. The ISO 513 is a standard that classifies materials based on their machinability and provides guidelines for cutting speeds, feeds, and tool selection. ISO 513 provides a classification system for the machinability of materials, organizing them into categories based on the characteristics which influence their behavior during machining processes. The main categories include:

Now, let's dig into the details. Below you'll find the key components of an end mill and how they relate to machining different ISO 513 material types:

End Mill Anatomy OverviewThe anatomy of an end mill refers to its various components and features, each of which plays a critical role in its cutting performance. End mills are rotary cutting tools used in milling operations to remove material from a workpiece.

Here's a breakdown of the key parts of an end mill:

0 Comments

3125 V-MAC End Mill is unmatched Performance in High-Temp Alloys and Stainless Steels At Browne & Co, we are thrilled to introduce the latest addition to our cutting-edge tool lineup – the Fullerton Tool 3125 V-MAC End Mill. Engineered to perfection, this high-performance end mill has proven its mettle in milling aerospace high-temp alloys, stainless steels, and inconels, offering unsurpassed performance that sets it apart in the machining industry. The 3125 V-MAC high-performance end mill is your solution for tackling high cutting forces with ease. Designed for precision milling in aerospace materials inclduing high-temp alloys, stainless steels, and inconels, this tool delivers ultimate part finishes and reliable performance. 5 things you should remember about the new 2135 V-Mac!

3125 V-MAC Technical Specifications & Options

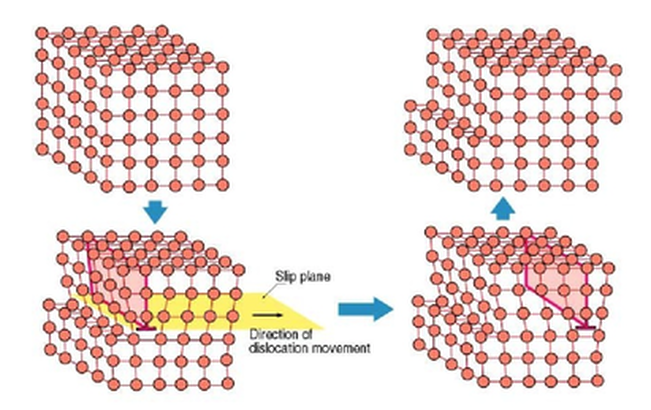

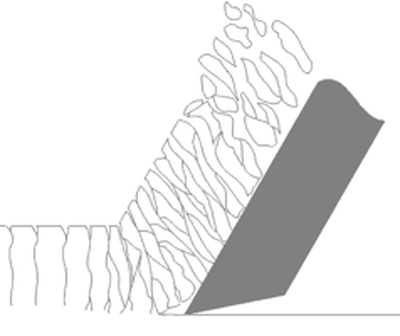

Experience the power of the Fullerton Tool 3125 V-MAC End Mill. Whether you're milling aerospace high-temp alloys, stainless steels, or inconels, this high-performance tool is engineered to exceed your expectations. Elevate your machining capabilities and achieve unparalleled results by getting started with the V-MAC today! Just click the button below! Contrary to popular terminology, metal is not “cut” as much as it is a “forced separation from itself.” To understand this, think of how molecules bond together. Molecules resemble our solar system with the nucleus represented by our Sun (or a carbon atom in the image) and the electrons represent by the various planets. When one molecule “bonds” with another it is as if two solar systems’ planets became intertwined into each others orbits with both solar systems sharing certain planets and making the whole larger than the sum if it’s parts. When we use a cutting tool we are inducing these bonds to break apart. The “machinability” of a particular metal partially defines how easily the material separates from itself. The basic mechanics of forming a chip are the same regardless of the base material. As the cutting tool engages the workpiece, the material directly ahead of the tool is sheared and deformed under tremendous pressure. The deformed material then seeks to relieve its stressed condition by fracturing and flowing into the space above the tool in the form of a chip. The important difference is how the chip typically forms in various materials. Regardless of the tool being used or the metal being cut, the chip forming process occurs by a mechanism called plastic deformation. This deformation can be visualized as shearing. That is when a metal is subjected to a load exceeding its elastic limit. The crystals of the metal elongate through an action of slipping or shearing, which takes place within the crystals and between adjacent crystals. Type 1: Discontinuous ChipCast Iron, Hard Brass and other materials that produce a Powdery chip. “Discontinuous Chip - Discontinuous or segmented chips are produced when brittle metal such as cast iron and hard bronze are cut or when some ductile metals are cut under poor cutting conditions.

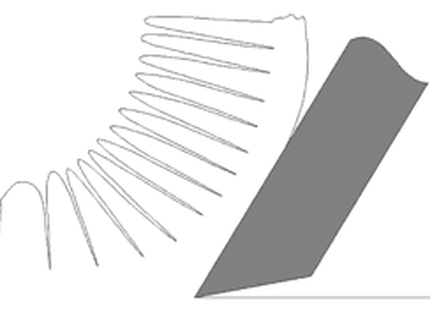

Type 2: Continuous ChipMedium to High carbon and alloy Steels – Long Chipping Materials “Continuous Chip - Continuous chips are a continuous ribbon produced when the flow of metal next to the tool face is not greatly restricted by a built-up edge or friction at the chip tool interface. The continuous ribbon chip is considered ideal for efficient cutting action because it results in better finishes. Unlike the Type 1 chip, fractures or ruptures do not occur here, because of the ductile nature of the metal.”

Type 3: Sheared ChipsLow carbon Steels, Stainless Steels, Nickel Alloys, Titanium, Copper, Aluminum and other soft, “gummy’ Materials. Sheared Chips or as some refer to it “Continuous Chip with a Built-up Edge (BUE). The metal ahead of the cutting tool is compressed and forms a chip which begins to flow along the chip-tool interface.

These metals readily deform in front of the cutting edge and have to be "sheared" by the tool. What the above paragraph doesn’t tell you is that these materials require tools with sharper cutting edges than those used for machining cast Iron or higher carbon content Steels. The chips tend to compress onto the face of the tool which can result in built-up edge.

The chips formed when cutting these metals are thicker than those produced by Medium Carbon or Alloy Steels at the same Feed Rates and Depths of Cut. These thicker chips are stronger and harder to break. Destiny Tool, through a combination of rake face geometry, carbide substrate and concentricity tolerance is able to enable the chip to more readily "separate from itself" which not only improves MRR, but also reduced heat into the end mill and thereby extends tool life as the feed rate increases. High strength metals such as Stainless Steel, Nickel Alloys and Titanium generate high heat and high cutting pressures in the area of the cutting edge. This results in reduced tool life compared to easier to machine materials.

VAPOR™ is a high feed indexable mill that maximizes metal removal rates. Utilizing light depth of cut (DOC) combined with extreme feed per tooth (FPT) to increase productivity. Dapra Corporation has announced the DAPRA Next Technology - High Feed Indexable Milling Platform - "VAPOR™ powered by TRI-X2". VAPOR™ is ideal for extreme machining. The VAPOR™ platform has unique elements in body design and TRI-X2 insert geometry for higher metal removal rates and extended tool life. The design is created for lighter, faster cutting and versatility through positive cutting geometry and excellent ramping capability. It's designed with a new double-sided insert series for lower cost per usable cutting edge. Inserts are installed with a large insert screw for longevity and easy indexing. This makes the advanced design highly shock resistant through-hardened steel.

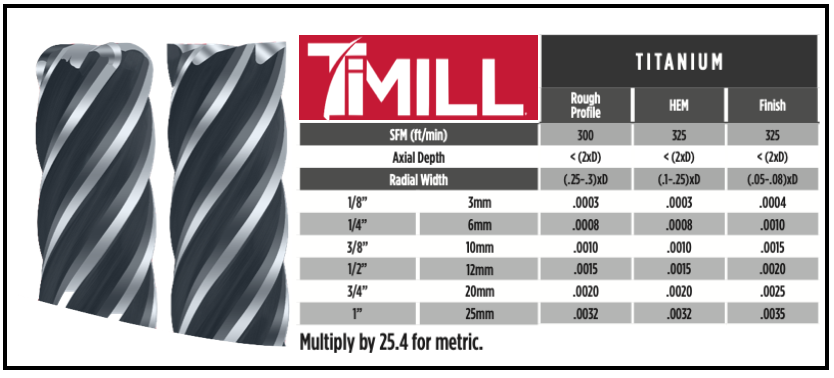

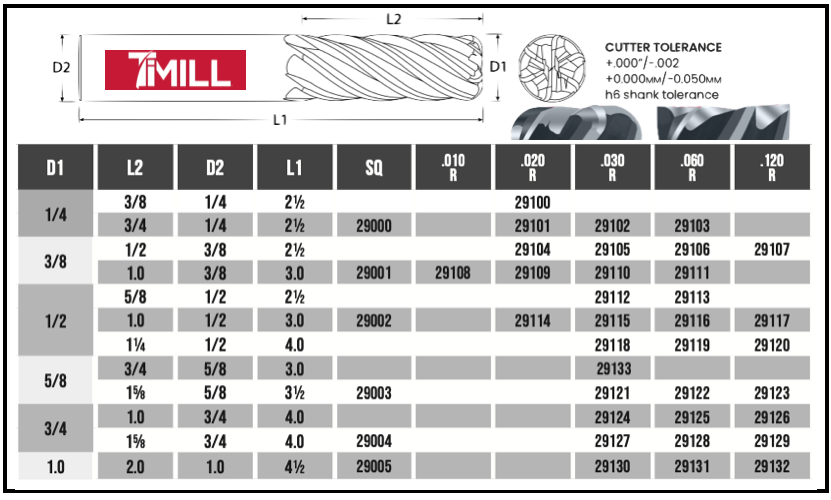

Looking for an end mill with unsurpassed performance in high-efficiency milling of Titanium? The new Fullerton 3116 TiMill end mill may be just what you need. Titanium is half the weight of steel and twice the strength of aluminum: It's a high strength, light weight material with excellent fatigue performance, super durable in high stress environments and corrosion resistant.  As a result of titanium's material properties it's making it become evermore popular in the aerospace, defense, shipbuilding, medical adn dental industries. It's also what makes it considered a "more difficult to machine" material. Let's dig into that a bit more. Generally, titanium grades 1 through 4 are considered commercially pure titanium with varying requirements on ultimate tensile strength while Grade 5 is what is most often seen in the machining industry. It's often alloyed with 6% aluminum and 4% vanadium. This is what is commonly known as 6Al4V or Ti 6-4. Also quite common is 4Al4V or Ti 4-4. Why difficult? Well, first it has low Young’s modulus meaning that is more elastic than other materails: It's "gummy" which often causes spring back and chatter during machining and can readily generate long stringy chips if you don't have the correct edge prep. On top that, it's also prone to work hardening and galling super easily. You've got to keep the cutter in-the-cut: Insert cutters just aren't as good as solid endmills at doing this. Next, titanium does not have good thermal conduction properties like aluminum. Instead of heat being evacuated in the chips or transferred to the base material, heat tends to be transferred to the cutting tool which reduces it's tool life. Heat kills. Tool life declines. The right coating helps. The final icing on the cake is that titanium is prone to work hardening. During uniaxial loading, the initial rate of hardening is higher in compression so if you come back for another pass you need to get under the work hardened layer, that is, leave enough material for a finish pass to get under the layer or your tool life will suffer and your part finishes will decline with it. Ideally, finish to size in the final pass if you can. The trick to machining titanium has always been to keep consistent coolant flow to evacuate the chips and maintain a consistent chip load. Again, rough to your finish size. Don't let it work harden. That's what we've learned about titanium over the past couple of decades. There has been a ton of research on titanium's properties and that research has led to further refinement of the cutting tool geometry at Fullerton. The design of Fullerton's 3116 TiMill is based upon over a decade of aerospace testing and development and addresses many of the machining issues that Titanium presents. It's a 6-flute tool built with a 38°helix. The increased number of flutes allows for the tools to remain "in the cut" longer and more consistently. It doesn't induce as much heat as a lower number of flutes tends to do. instead, it's consistent. The 38°helix evacuates the chip at a more optimum angle than a 35°, 37.5° or 40° helix that predecessors made by competitors have tried.

Speeds and Feeds are Critical* IT'S MADE FOR TITANIUM! So that means it is NOT Recommended for High Si Aluminum (>10%), Low Si Aluminum (<10%), Composites, Plastics, Brass & Copper, or Graphite. NOT Recommended! Choose your SizeCHARDON, OH - Browne & Co is excited to announce that they begin representation of Dapra Corporation products in December 2022.

Dapra specializes in the design, service, and support of American-made, high-performance indexable carbide milling tools for a broad range of operations. Dapra Corporation is a U.S.-based, multi-generation family-owned parent company to multiple brands which provides high-quality engineered solutions for various manufacturing and industrial markets. From indexable cutting tools to permanent part marking equipment Dapra Corporation continues to develop and invest in solutions to empower the success of manufacturers across North America. For over 65 years Dapra has provided milling, workholding, and power tool solutions to a wide array of manufacturing segments including aerospace, automotive, mold and die, and firearm. With their proven high-performance solutions combined with industry-leading application expertise and a robust distribution network Dapra has earned the trust of businesses from around the world. From small workshops to globally diversified manufacturers, they are more than a supplier, they are a partner in yours and our success. According to David Browne at Browne & Co., "At our core we have always had a very strong presence in CNC milling products. We're at the spindle. Dapra really matches what our company does and we're excited to launch into 2023 with Dapra's high performance milling products." Browne & Co. is excited to work with our customers with these premiere products that include:

Guest Blog by Mark Donze at Fullerton Tool Have you ever wondered if you should purchase high-performance end mills or general-purpose end mills and what the benefit of purchasing one over the other is? If so, we have put together a list of factors to consider to help you make the right decision for next time. General Purpose End MillsFirst, let's discuss general purpose end mills. General Purpose (GP) End Mills are standard single, 2, 3, or 4 flute geometry end mills made for use in a wide variety of materials. Benefits of General Purpose End Mills:

High-Performance End MillsNext, High-Performance (HP) End Mills contain specialized geometries for a specific material being cut. Benefits of High-Performance End Mills:

With this information in mind, if you are a company that does small runs in a wide variety of materials you may prefer GP end mills. Whereas, if you are making high-volume parts where cycle-time and up-time are king, you may prefer an HP end mill for your use. Remember, there are no hard lines drawn. Each application is different and preference is ultimately up to you, the end-user.

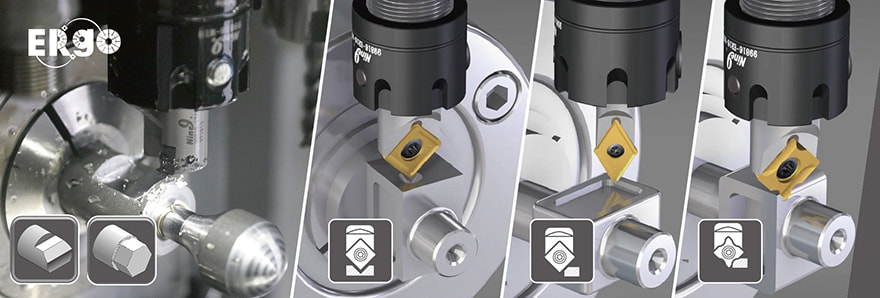

If you aren't sure, you can contact your Fullerton authorized distributor to help make this decision. We will work with you to get the end results you desire with a wide variety of both GP and HP end mills available. We even have some tooling where we apply HP coatings to GP tools to help you get the most out of your cutting tool investments. We have a huge selection of inventory items and of course, if you need a special tailored tool to your specific needs, we have engineering and application knowledge to get the most out of your cutting tool budget. We also have resources on our website to help you navigate which tool is the best for your needs. Discover what end mills are recommended for your material and application by using the Fullerton Tool End Mill Selection Guide You can also explore and search for tooling by material, application, or tool specs as well as recommended speeds and feeds by series which you can access at the search button below. "Ergo" is a new trademark of Nine9 for ER type indexable cutter. The cutter is assembly kit by the 3 parts including Ergo nut, high strength Ergo pin and Integrated ER taper. Patented design mechanism to produce high clamping Forces and high runout accurancy. It's perfectly suitable for driven tools and spindles with ER interface of CNC turning centers and swiss type automatic lathes such as Star, Citizen, Tsugami, Doosan, Tornos, INDEX, EMAG and so on. The Ergo provides types ER11, ER16, ER20, ER25 taper-shank cutter. The ergo tooling include milling cutter, spot drill, chamfering tool, corner rounding, engraving tool, deburring tool, center drill and boring tool.

by Steven Oszust Jr. at Fullerton Tool This month we will focus on one of our most successful legacy tools, the Fullerton Tool's 3400 Harmon-i-Cut end mill. Nearly two decades ago, we recognized the advancements in machining technology demanded increasingly aggressive machining operations to enhance productivity and reduce production costs.

Advancements in spindle technology enabled greater spindle speeds while maintaining the necessary power to perform more aggressive cutting operations. With the greater acceptance and application of high-speed machining (HSM) practices in programming, spindle speeds were increased to a range which was greater than those traditionally used for an increase in material removal rates (MRR) over traditional tools. High-speed machining is achieved by increased axial depth of cut and higher spindle speeds, combined with constant chip loads requiring new high-performance tooling design. One limitation in achievable MRR is self-excited vibrations of the cutting tools, known as chatter. Chatter is caused by variations in the inconsistent chip thickness caused when the vibration of the tooth currently engaged in the cut is out of phase with the vibration of the previous tooth. Specifically engineered geometries greatly reduce chatter leading to smoother running, faster feed rates. These tools are ideal for all roughing and finishing operations, offering longer tool life and improved surface finishes. Harmon-i-cut end mills have engineered flute shape designed for maximum rigidity, variable helix, variable rake, superb chip evacuation, and excellent shearing action. Reduced load pressures and super stiff design promotes less chatter, achieving rapid Harmonic-free stock removal at rates never seen before. By utilizing chip thinning strategies, significant increases in productivity and tool life can be achieved. These methods are also helpful when using machines with less power and stability. Even with weaker machines and less stable working conditions, very high cutting parameters can be achieved. These strategies are particularly effective for increasing process reliability in difficult to machine materials or challenging applications. Consider Fullerton Tool's 3400 series Harmon-i-cut a cut above the rest. With our vast inventory of sizes and configurations, we can provide a solution for your needs. Contact Browne Sales to get started At Fullerton Tool ,Our primary purpose is to provide our customers with cost-effective, high-quality, solid carbide round tool solutions at competitive prices. In the past we have discussed our consistency in our processes, and foundational approach to tool designs.

These traits can best be described as the basis for Functional Value. In the case of our general purpose end mills, functional value involves all the core processes and systems that customers are not paying for. These processes and systems are deeply engrained in our culture. Often development for the higher end, performance side of our offering, these systems naturally trickle down to the general purpose tools automatically in our tool strategy. The benefits of this tool strategy can be seen in everything we do. The nearly 150 years combined experience in our production engineering team, makes Fullerton one of the most detail oriented companies in the industry. Our innovative manufacturing processes and years of experience ensure the best possible value for cost conscious metalworking consumers. Consider our General Purpose End Mills a cut above the rest. With our vast inventory of sizes, configurations, and coatings we can provide a solution for your needs. Start your search for the perfect General Purpose End Mill on the Fullerton Tool Website or contact your dedicated regional managers at Browne Sales for application recommendations. |

AuthorWe've compiled the latest news and technical information about our principals and our market that we hope you find informative! Archives

June 2024

Categories

All

|

|

Browne & Co., Inc.

9605 Tanager Drive Chardon, Ohio 44024 |

© 2024 Browne & Co., Inc. All Rights Reserved

web design by Rapid Production Marketing |

RSS Feed

RSS Feed