But more often than not, loads are too heavy for the slings that support them. This results to workers getting injured or killed because loads fall on them or hit them. The same thing happens when operators are not trained in the proper use and maintenance of slings. Slings end up being out of the operator’s control or losing their strength because of abuse or wear.

Performance Characteristics of Webbing

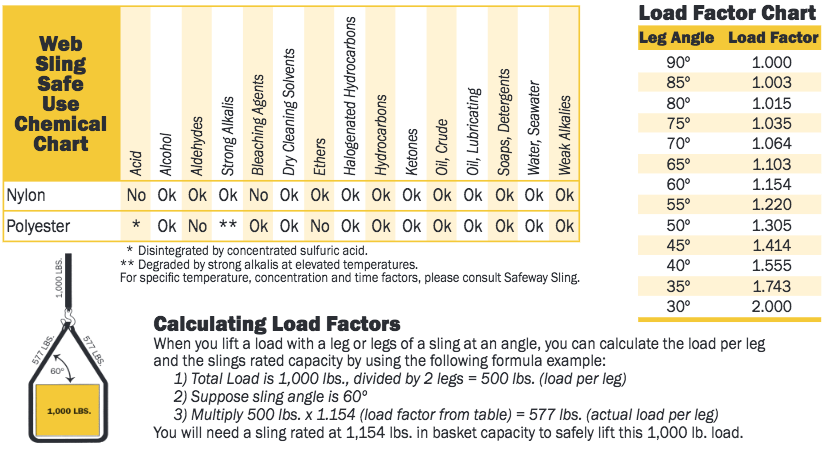

| Nylon The most widely used general purpose synthetic web sling, is unaffected by grease and oil. It has good chemical resistance to aldehydes, ethers, and strong alkalis; but is not suitable for use with acids and bleaching agents or at temperatures in excess of 194 degrees F (90º C). Stretch at rated capacity is approximately 8-10% | Polyester Used mainly where acid conditions are present or a minimum stretch is desired, polyester is unaffected by common acids and hot bleaching agents. It is not suitable for use with concentrated sulfuric acids, alkalis or at temperatures in excess of 194 degrees F (90º C). Stretch at rated capacity is approximately 3% (untreated) |

Top Tips for Sling Safety

- Selection of slings must be based on their intended use, the type and size of load, and the environmental conditions of the worksite.

- Before inspecting a sling, clean it thoroughly as dirt and oil may hide damage. Do the same right after using the sling to check if it has damage before you store it.

- Before and after using a sling, it must be inspected by the operator. They should check for broken wires, damaged rope strands and other signs of wear or defects.

- Discard wire rope slings when they show the following signs:

- Excessive broken wires

- Severe corrosion

- A one-third reduction in outer wire diameter

- Damage or displacement of end fittings like rings, hooks, collars, and links.

- Distortion, bird caging, kinking

- Localized wear on the outside

- Excessive broken wires

- Lubricate every rope sling “in the field” to prolong their service. The heavier the loads, the more adverse the environmental conditions, the greater the number of bends, the more frequently you should lubricate it.

- When carrying loads, ensure that they are not clamped, lagged or bolted to the floor.

- Before lifting loads all the way, check the tension on the sling. You can do this by raising the load a few inches, stopping and checking for proper balance.

- Make sure the path of travel is clear of workers whenever you raise, lower or lower the load.

- Slowly take up the slack in the sling to guard against shock loading. Be doubly cautious when applying power at the beginning of the lift. This way, you can prevent jerking. You can also prevent this hazard by slowly accelerating and decelerating the equipment.

- The operator must maintain a close watch on the slings and equipment they are using. In the event of an accident, the operator must immediately shut down all equipment and report the accident to the supervisor. Before resuming operations, the cause of the accident must be determined first.

- Only one person should be assigned to control a lift or give signals to the hoist or crane operator.

- Never leave the load suspended in air.

- Store the slings in a dry, well ventilated building or shed. Never store them on the ground. It’s best to hang them in a wall or rack.

RSS Feed

RSS Feed