|

written, compiled and edited by Bernard Martin Class of fit for a cutting tap refers to the specific tolerance or fit that is desired between the threads of the tap and the threads of the hole it is being used to create. In other words, it defines how tightly or loosely the threads should mesh together. The class of fit is typically expressed using a combination of letters and numbers. The most commonly used standards for class of fit are the Unified Thread Standard (UTS) and the ISO metric thread standard. In the UTS, the class of fit is denoted by a combination of a letter and a number, such as 2B, 3A, etc. In the ISO metric thread standard, it is represented by a combination of a letter and a number, such as 6g, 4h, etc. For cutting taps, the class of fit is usually specified based on the intended application and the level of precision required. The class of fit can affect factors like the ease of assembly, the strength of the threaded connection, and the ability to engage the threads smoothly during tapping. A classification system exists for ease of manufacture and interchangeability of fabricated threaded items. Most, but certainly not all, threaded items are made to a UTS classification standard. This system is analogous to the fits used with assembled parts.

The letter suffix "A" or "B" denotes whether the threads are external or internal, respectively. Classes 1A, 2A, 3A apply to external threads; Classes 1B, 2B, 3B apply to internal threads Here are some common classes of fit for cutting taps:

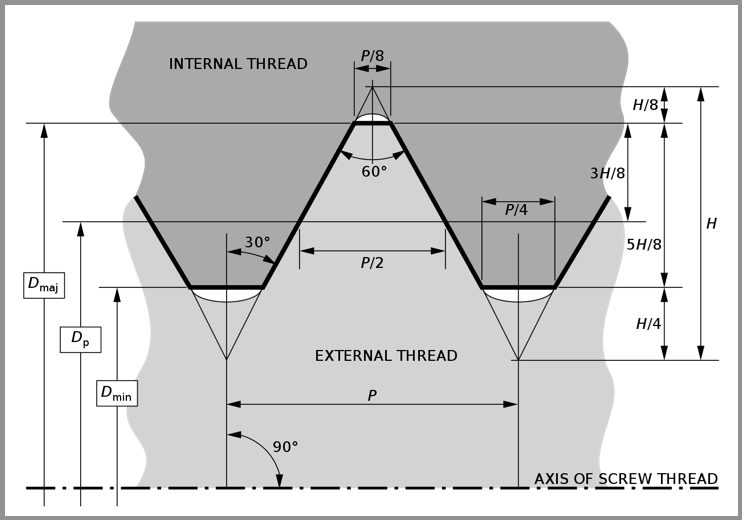

The standard designation for a UTS thread is a number indicating the nominal (major) diameter of the thread, followed by the pitch measured in threads per inch. For diameters smaller than 1⁄4 inch, the diameter is indicated by an integer number defined in the standard; for all other diameters, the inch figure is given.

This number pair is optionally followed by the letters UNC, UNF or UNEF (Unified) if the diameter-pitch combination is from the coarse, fine, or extra fineseries, and may also be followed by a tolerance class. Example: #6-32 UNC 2B (major diameter: 0.1380 inch, pitch: 32 tpi)

0 Comments

Browne & Co has been appointed as Regaional Managers for Regal Cutting Tools. They will be responsibilve for distributor and technical support for the Kentucky, Ohio, and Western Pennsylvania market areas. Regal Cutting Tools has been manufacturing world-class cutting tools since 1955 Regal offers a high performance SuperTuf series of taps for the demanding difficult to machine materials. Regal also manufactures special taps from blanks with as little as 24 hour notice.

According to Dave Browne, President of Browne & Co, "Regal Cutting Tools. is a well established and trusted brand within the metalcutting industry. Their full line of taps as well as their tap specials capabilities really compliment our product mix and fills an area we have pretty deep experience in but didn't have a product to recommend. We're really looking forward to working with our customers and running these tools!" This is Part 2 of our series on Carbide taps. Be sure to check out Part 1 if you missed it: Carbide Taps: A Practical User’s Guide to When, What, How and Why Carbide taps have a lot of advantages, especially when you’re cutting very abrasive materials. The absolute best choice for tapping glass-filled polycarbonates, space age alloys, nonferrous materials, cast iron, and a range of other exotic materials, their anti-friction qualities lead to a longer tool life.

Standard Screw Thread Insert Taps S.T.I. (Screw Thread Insert) Taps are special taps for helical coil wire screw thread inserts, which provide positive means for protecting and strengthening tapped threads in any material. Typically used on softer abrasive materials, these taps create more accurate thread forms than other standard taps. When you need to be precise, these carbide taps are the best choice. STI taps are correctly sized to produce an internal thread that accommodates a helical coil wire screw thread insert. The insert, in turn, will accept a screw thread of the nominal size and pitch at final assembly. Screw thread inserts provide stronger tapped threads (stronger assemblies) due to a more balanced distribution of loads throughout the length of thread engagement. Thread Forming Tap  Roll Taps (aka, Thread forming taps, Form taps0 offer improved thread quality and strength due to the fluteless design, and therefore allows for greater fastener strength in the threaded product. This tap does not cut, so it is “chipless,” and therefore will not cause a chip problem. This is why thread forming, over thread cutting, eliminates costly and time-consuming chip clean-up and disposal. Thread forming taps are fluteless and include lubrication grooves. Not intended for general applications, they work by displacing the metal without removing it. Because of this, they are ideal for chip removal in blind holes. Roll Thread Forming Taps Features

Carbide Insert Taps A cost-efficient solution, only the cutting portion of insert taps is made from carbide. Their HSS body is able to absorb vibration and account for their lack of rigidity. If you’re considering testing the waters with carbide taps, insert taps are a great option. It's a very economical way to utilize the benefits of carbide with solid carbide cutting face inserts meticulously brazed to a H.S.S. tap body. Carbide Insert Tap Features

|

AuthorWe've compiled the latest news and technical information about our principals and our market that we hope you find informative! Archives

June 2024

Categories

All

|

|

Browne & Co., Inc.

9605 Tanager Drive Chardon, Ohio 44024 |

© 2024 Browne & Co., Inc. All Rights Reserved

web design by Rapid Production Marketing |

RSS Feed

RSS Feed