|

Successful initiatives include developing advanced air mobility (AAM) in the state. December 23, 2022, Posted by Eric Brothers in Aerospace Manufacturing & Design JobsOhio is Ohio's private, nonprofit economic development corporation that works outside but alongside state government to support the creation of jobs and sustainable economic growth for all Ohioans. The Q4 President's Report to the Board highlights programs that yield a return on investment and position the state as one of the world's great automotive hubs and a leader in aviation and the advanced air mobility (AAM) sector.

JobsOhio President and CEO J.P. Nauseef notes that as the No. 1 supplier state to Boeing and Airbus, Ohio is a powerhouse producer of systems and parts for the aerospace industry. Earlier in the year, Sierra Nevada Corp. announced plans to build one of the largest aircraft maintenance hangars in America in Dayton, bringing maintenance and modification of military aircraft to Ohio. The state also plays a crucial role in developing AAM technologies with robust supply chains, test markets, partners, and enabling legislation for public and private sector entities. From flying vehicles to air taxis to NASA AAM Mission supporters, Ohio is a leader in AAM and aeronautics research. Credit goes to Ohio lawmakers for opening the skies for unmanned aircraft systems traffic management (UTM) and urban air mobility (UAM) of the future. In September, the Springfield-Beckley Municipal Airport hosted a groundbreaking for the National Advanced Air Mobility Center of Excellence. The NAAMCE is funded by the Department of Defense, JobsOhio, and the City of Springfield to facilitate collaborations between the Air Force Research Laboratory, NASA, the Ohio Unmanned Aircraft Systems Center, local colleges and universities, and private industry to support the development of AAM projects.

0 Comments

IMTS 2022 Preview: Arno, Fullerton, Everede, Haimer & Precision Brand to Feature New Products!9/8/2022 If you're making plans to attend IMTS, be sure and add this group of terrific manufacturers to your your show planner! Just click on the name, building location or image and you can add them to your "MyShowPlanner" ARNO-Werkzeuge USA LLCARNO FAST CHANGE: Make More Parts Per Shift On Your Swiss Machine How do you increase spindle up-time on your sliding head Swiss lathe?

Fullerton ToolManufactures High Performance Solid Carbide Round Cutting Tools. Endmills, Drills, Reamers, Saws, Burrs, Keyseat Cutters, PCD, and Custom Special Tools.

Everede Tool Co.Everede is a Manufacturer of Indexable Boring Bars and Inserts. Catalog includes Steel, Carbide, Carbide Bars andmore Exclusive USA representative for Nine9 and Duemmel. Nine9 manufacturer’s high quality unique indexable Engraving, Spotting... Duemmel manufacturer’s high quality Indexable carbide cutting tools for micro boring, grooving Haimer USAHAIMER is a first class German Tool Holder manufacturer. From the basics of face-mill arbors and ER collet chucks, all the way up to High Precision Collet and Shrink Fit Chucks, HAIMER has the tools necessary to satisfy and exceed your machining center needs. Their product line includes the most extensive taper and size offerings from any HSK, CAT, BT, SK, PSC and KM tapers to any inch or metric size available. Their product portfolio, which also holds shrink fit, presetting & balancing machines, 3D-sensors, and cutting tools, addresses the machining process from spindle to part, giving the customer a complete machining solution. Precision Brand Products, Inc.For over 75 years, Precision Brand Products has been the benchmark for toolroom products. Our product line of over 2800 products, including shim stock, feeler gauges, key stock, hose clamps and more, has kept pace with the changes and advances in manufacturing technology and methods worldwide.

Since 1957, General Die Casters has worked closely with their customers, to design, manufacture, and deliver the custom die castings they demand. In March 2010 they opened their new 90,000 square foot expansion casting foundry in Twinsburg, OH. service the Appliance, Automotive, Commercial, Computers & Peripherals, Electrical, Industrial, Lawn & Garden, Recreational and Transportation Industries.

Advanced Chemical Solutions was invited to discuss coolants that would not only perform well but also not have an odor, foam or cause dermatitis. Mark Pierson from ACS with closely with Keith Kish, the Director of Manufacturing Engineering at General Die Casters. According to Keith, "I was looking for an economical coolant that would not stink, foam or have skin issues for our employees. Advanced Chemical Solutions evaluated our facility and provided Nano Tech 6800 for testing." General Die Casters has a good number of CNC machines from Brother, Mori Seiki, Chiron, Takisowa, DMC, Kitako, and a good number Haas machines. Taking good care of their employees is important to the the company. Recently, several employees celebrated 20 years of service at the company. One of them was Anderson Grant, the first shift operator “In most companies, it’s very rare to see employees who reach 20 years of employment. At General Die Casters, it is common to see people reach 35 years at the company. We have a work culture where there is mutual respect and support of one another. When one of us succeeds, we all succeed”, says Anderson. Having odor free coolant that didn't cause dermatitis is part of keeping employee morale high. According to Keith, "Nano Tech 6800 is absolutely the best coolant we have ever used in our machines. No Monday morning odor, coolant stays fresh and clean." But what about tool life? Keith tells us "This coolant has dramatically improved our work environment helping to keep our machines cleaner and improving our tool life." Guest Blog by Mark Donze at Fullerton Tool Have you ever wondered if you should purchase high-performance end mills or general-purpose end mills and what the benefit of purchasing one over the other is? If so, we have put together a list of factors to consider to help you make the right decision for next time. General Purpose End MillsFirst, let's discuss general purpose end mills. General Purpose (GP) End Mills are standard single, 2, 3, or 4 flute geometry end mills made for use in a wide variety of materials. Benefits of General Purpose End Mills:

High-Performance End MillsNext, High-Performance (HP) End Mills contain specialized geometries for a specific material being cut. Benefits of High-Performance End Mills:

With this information in mind, if you are a company that does small runs in a wide variety of materials you may prefer GP end mills. Whereas, if you are making high-volume parts where cycle-time and up-time are king, you may prefer an HP end mill for your use. Remember, there are no hard lines drawn. Each application is different and preference is ultimately up to you, the end-user.

If you aren't sure, you can contact your Fullerton authorized distributor to help make this decision. We will work with you to get the end results you desire with a wide variety of both GP and HP end mills available. We even have some tooling where we apply HP coatings to GP tools to help you get the most out of your cutting tool investments. We have a huge selection of inventory items and of course, if you need a special tailored tool to your specific needs, we have engineering and application knowledge to get the most out of your cutting tool budget. We also have resources on our website to help you navigate which tool is the best for your needs. Discover what end mills are recommended for your material and application by using the Fullerton Tool End Mill Selection Guide You can also explore and search for tooling by material, application, or tool specs as well as recommended speeds and feeds by series which you can access at the search button below. At Fullerton Tool ,Our primary purpose is to provide our customers with cost-effective, high-quality, solid carbide round tool solutions at competitive prices. In the past we have discussed our consistency in our processes, and foundational approach to tool designs.

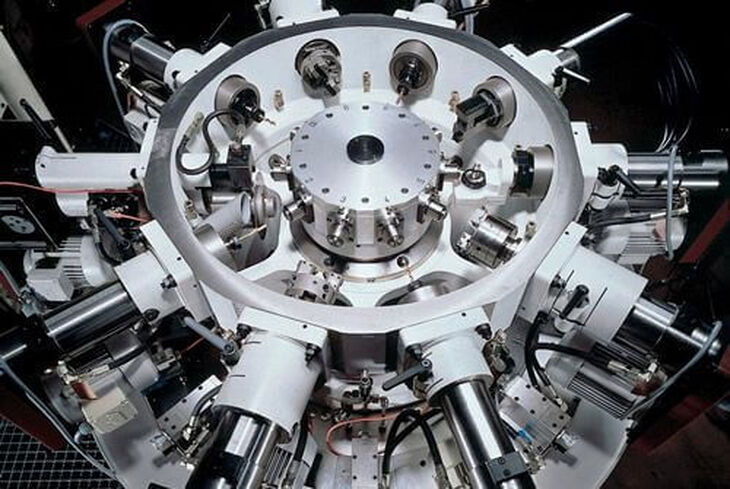

These traits can best be described as the basis for Functional Value. In the case of our general purpose end mills, functional value involves all the core processes and systems that customers are not paying for. These processes and systems are deeply engrained in our culture. Often development for the higher end, performance side of our offering, these systems naturally trickle down to the general purpose tools automatically in our tool strategy. The benefits of this tool strategy can be seen in everything we do. The nearly 150 years combined experience in our production engineering team, makes Fullerton one of the most detail oriented companies in the industry. Our innovative manufacturing processes and years of experience ensure the best possible value for cost conscious metalworking consumers. Consider our General Purpose End Mills a cut above the rest. With our vast inventory of sizes, configurations, and coatings we can provide a solution for your needs. Start your search for the perfect General Purpose End Mill on the Fullerton Tool Website or contact your dedicated regional managers at Browne Sales for application recommendations. Advanced Chemical Solutions introduces FormKut Light with a proprietary blend of additives specifically tailored to Hydromat Rotary Transfer machining, providing faster cutting speeds, greater feed rates and higher part quality with superior surface finishes.

Our Formkut light oil formulation is designed for medium to moderately difficult machining on steel, stainless steel, and nonferrous materials. A transparent chlorinated cutting oil allows operators easy visual references to the tooling. Formkut light is an economical product that is appreciated by machinists for its lack of odor and non-irritating properties. Please contact Browne & Company for your closest, authorized, Advanced Chemical Solutions distributor. |

AuthorWe've compiled the latest news and technical information about our principals and our market that we hope you find informative! Archives

June 2024

Categories

All

|

|

Browne & Co., Inc.

9605 Tanager Drive Chardon, Ohio 44024 |

© 2024 Browne & Co., Inc. All Rights Reserved

web design by Rapid Production Marketing |

RSS Feed

RSS Feed