|

You probably still remember the 1997 action-thriller film “Air Force One” and the movie’s famous scene, when Harrison Ford, starring as the president, pulls hijacker Gary Oldman’s parachute cord and growls, “Get off my plane!” But how much do you know about the real Air Force One, the planes (yes, plural) that fly the president around the country and even the world? Unsurprisingly, Air Force One planes have as many bells and whistles as you can imagine. From serving as a de-facto bunker during a potential nuclear attack to flying well above where a commercial airliner can go, there are a lot of fascinating things to know about Air Force One. The current planes were made by Boeing Although many different types of planes have been used as Air Force One, the current planes in opperation are both Boeing 747-200 aircraft. It has four engines and is a successor to the Boeing 707, which President Dwight Eisenhower added to the fleet in ’58. Eisenhower also flew in Lockheed C-121 Super Constellations. There's a Marine One, too.

The president doesn’t always fly on airplanes. Sometimes, he takes a helicopter. Marine One is the radio call sign for a Marine Corps helicopter transporting the president. Lockheed is building six new helicopters for Marine One, and the first is expected to enter service in 2020, according to CNBC. Helicopters in the Marine One fleet are equipped with ballistic armor and antimissile defenses, and the pilots who fly them, from Marine Helicopter Squadron One, are known as the Nighthawks.

0 Comments

Recently we had an application question at North American Tool. A customer had opened up the drilled hole to 55 percent of thread in hopes of reducing wear and increasing tool life. Instead, it lead to the cut tap breaking at the first full thread of engagement. That prompted a engineering discussion and is the basis of this technical article to address this very common misperception. If a tap doesn’t create the hole, why is the hole size so important?

This leaves the good machinist to select a drill that is more or less than 75%. If 75% is good, then a higher number is better, right? WRONG (in many cases). On page 115 of the current North American Tool catalog a range for percentage of threads from 50% to 85%, with the recommended range between 65% and 75%. This guideline range to use is a reflection of several factors:

In higher tensile steels, larger hole sizes (less percentage of thread) may work better to reduce torque in tapping. When using oversize hole diameters, the tap should also have an oversize chamfer point diameter so all threads in chamfer are cutting and not just dropping in a hole. Such was the case with the application porblem. As was stated above the operator thought that by increasing the drill diameter size would lead to better tool life. Instead, because the diameter was of the hole was so large the cut tap did not engage the threads along the chamfer length and instead engaged at the first full thread at the end of the chamfer. The caused premature wear and stress on the that thread in the flutes and eventually to catastrophic failure. The solution was a modified tap from North American Tool. Summary: You've got to use the correct tap for the application! At the end of the day, taps are made to very strict tolerances, often much more so than the piece parts they are called on to machine, and the first place one might want to find blame is with the tap.

Why? Because;

What if one manufacturer makes a tap that works and another one made by a different company doesn’t work at all? In all likelihood, the “general purpose” of one is closer to the correct geometry for the application. One might get a completely different result if another material were being machined. Therefore it is always best to order a tap for the specific application. Ohio is the Nation’s Gateway to the Moon, Mars and Our Future: by Janet Kavandi - Former Astronaut & Director of NASA’s Glenn Research Center in Cleveland

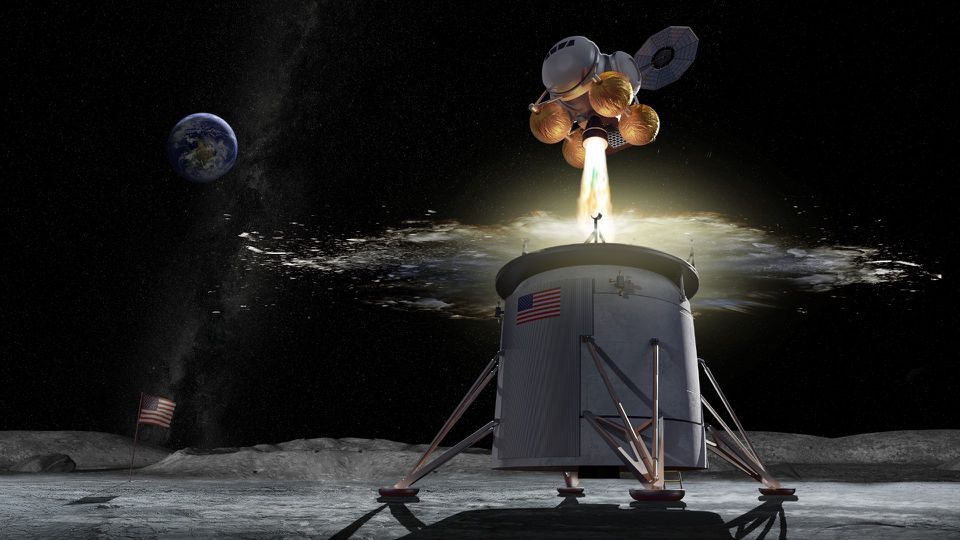

CLEVELAND -- Ohio is the aerospace state. Our history is unrivaled by any other state when it comes to achievements in the air and in space. Home to the Wright Brothers. Birthplace of John Glenn and Neil Armstrong. The Buckeye State has produced some 25 astronauts, and their achievements make up a significant part of NASA’s legacy. That’s why NASA’s Artemis Program is calling on Ohio to make landing humans on the moon by 2024 a reality. Once there, we will quickly and sustainably explore the moon and its resources, and use what we learn to enable our next great endeavor – human exploration of Mars. Marcus Schellinger, a rising senior in a Rock County High School (WI) on track to graduate at the end of the 2019-20 school year has spent the last six weeks working at North American Tool in South Beloit, IL. Marcus had to take the initiative to apply online to the Rock County 5.0 program (in its second year) a part of the Rock County Economic Development Committee.  Marcus Schellinger with Jeff Sherman, Director of Manufacturing , North American Tool Marcus Schellinger with Jeff Sherman, Director of Manufacturing , North American Tool Marcus was assigned to work a CNC Mill and a CNC Lathe in the Bar Steel A department of North American Tool Corporation. This is where the making of a tool begins and Marcus proved more than capable. “It gave me insight into the methodology behind working that I can take and apply to school” said Marcus. “I was given responsibilities that enabled me to apply the knowledge and skills I have learned in school course work” reports Marcus. Jeff Sherman, the Director of Manufacturing at North American Tool said he was extremely impressed with Marcus and his work ethic and willingness to learn. Marcus worked with Flint Hansen day to day and “got to develop some faster methods to operate the machine”. The Rock County 5.0 program did a nice job at matching the skill set of the student with the opportunity available. The program was conceived and overseen by James Otterstein the Economic Development Manager of the Rock County Economic Development Committee. The idea was to “accelerate personal, as well as professional skills and career related exposure. This structured paid internship model will provide students like Marcus with a meaningful career pathway experience that will serve as a foundational element of their Academic & Career Plan. When asked what he would say to future students considering an internship at North American Tool , Marcus replied “I would tell them to ‘go for it’ and they would regret nothing.” Governor DeWine heads to Japan Sept. 8-13, seeking new opportunities for partnership between the island nation and Buckeye State. Japan is Ohio’s top international investor, with 72,860 Ohioans employed at 852 Japan-owned establishments across the state. (COLUMBUS, Ohio)—Ohio Governor Mike DeWine today announced he will lead a business development mission to Japan in September. Japan is Ohio’s top international investor, with more than 72,860 Ohioans employed at 852 different Japan-owned establishments across the state. Japan also was Ohio’s fifth largest export market for Ohio products in 2018, when Ohio firms exported more than $1.67 billion worth of products to Japan.  “Ohio and Japan share a special investment relationship, and my administration is committed to strengthening those ties,” said Governor DeWine. “This business development mission looks to find new opportunities for partnership and build upon the successes and ties that have benefitted the people of both Ohio and Japan.” Official meetings and events are scheduled from Sept. 8-13, 2019. In addition to growing relationships with current and prospective company investors, the Governor will seek to create more awareness of Ohio for company representatives, key influencers, and government leaders. J.P. Nauseef, JobsOhio president and chief investment officer, and Lydia Mihalik, director of the Ohio Development Services Agency, will join the Governor to support the mission. Anchoring the mission will be Governor DeWine’s visit to the 51st Midwest U.S.-Japan Association (MWJA) annual conference in Tokyo. MWJA is a bilateral organization comprised of the governments of ten U.S. Midwestern states, eight prefectures in Japan, and about 100 Japanese corporations. This will be the first visit by an Ohio Governor to the MWJA Annual Conference in more than a decade. In addition to the Governor’s delegation, more than 50 government and economic development officials will represent Ohio regions and communities at the conference. The mission will also include a visit to the Saitama Prefecture, Ohio’s sister state in Japan. Next year marks the 30th anniversary of the Ohio-Saitama sister state relationship. Governor DeWine plans to explore ways to build on the strong ties that have been established with Saitama. Governor DeWine has been deeply engaged in boosting Ohio investment since the beginning of his administration. On his third day in office, Governor DeWine attended the North American International Auto Show in Detroit, Mich., which included visits with Japanese automakers and suppliers. In February, Governor DeWine and First Lady Fran DeWine met with Japan's Ambassador to the United States, Shinsuke J. Sugiyama, at the Embassy of Japan during a meeting of the National Governors Association. In June, Governor DeWine took advocacy of Ohio to the SelectUSA Summit in Washington, D.C., where he also met Japanese business leaders and economic development professionals. Ohio's manufacturing industry is in pretty good shape, a new report found, though the state trails some of its nearby competitors. In the report from Ball State University, the state received a solid "B," the same grade it earned in the 2018 analysis of the data. The Ball State research measures each state's manufacturing industry in the following areas: logistics industry health; human capital; worker benefit costs; tax climate; expected fiscal liability; global reach; sector diversification; and productivity and innovation. Only five states received a grade of "A," but four of them are in the Midwest or border Ohio: Indiana, Iowa, Kentucky and Michigan. The fifth state receiving an "A" was South Carolina. Ohio's best grade within the categories came in logistics, where it earned an "A" for 2019, just as it did in 2018. Its lowest grade was in the worker benefit costs category, though Ohio rose to a "C-" this year from "D" a year ago. The only category in which Ohio declined was sector diversification, which fell to a "B-" from a "B." Here are the 2019 grades for Ohio:

AMONG THE GIANTS Two big Northeast Ohio manufacturing companies, Eaton and Parker Hannifin, are part of this Bloomberg Opinion roundup of prominent developments in the industrial sector.

Bloomberg Opinion's Brook Sutherland writes that Eaton's recently released second-quarter results "did little to endear analysts and investors to its current structure. While the company's aerospace and electrical divisions put up strong numbers despite currency pressures and a more challenging economic environment, the hydraulics and vehicle units were disappointments, yet again. Eaton now estimates organic growth in the hydraulics business will be flat to up 1% for the full year, down from a previous guide of 3% to 4%. Margin expectations for that unit were also slashed. In the vehicle division, Eaton sees as much as an 8% decline in organic sales this year." Asked by Goldman Sachs Group Inc. analyst Joe Ritchie about the hydraulics unit's long-term fit within Eaton's portfolio, CEO Craig Arnold pointed out that the company's overall performance was solid "despite the fact that we have one of our businesses that's not today firing on all cylinders." Sutherland concludes, "That's true, and yet while I'm wary of industrial companies' passion for breakups going too far, 'despite' is really the key word in Arnold's comments. This isn't a momentary slip-up for either the hydraulics or the vehicle business, and they're increasingly perceived as more cyclical roadblocks holding up even greater margin improvement and sales growth for the overall company. Arnold has signaled in the past that if the company can't get struggling businesses to targeted profitability levels, that could be a catalyst for divestiture. The piece also examines Parker's deal to buy Exotic Metals Forming Co. for $1.73 billion. Via Sutherland: The name might lead you to believe this company crafts metalworks on some sort of tropical island, but it's based in Washington and makes complex high-temperature engine components and exhaust-management systems for aircraft including the Boeing 737 Max and Lockheed Martin Corp.'s F-35 fighter jet. On the one hand, the addition of Exotic Metals will boost the share of Parker Hannifin's revenue tied to faster-growing, more profitable aerospace products to more than 20% by Bloomberg Intelligence's estimate, which will help to offset the sales slowdown in its industrial-products divisions. At about 13 times 2019 estimated adjusted Ebitda, the Exotic Metals deal is cheaper on that basis than the $3.7 billion acquisition of adhesives and coatings company Lord Corp. that Parker Hannifin announced earlier this year. But this is another debt-fueled bet on the aerospace industry at a time when skepticism is growing about how much longer the multiyear boom in that sector will last. The conclusion: "Exotic Metals' already-high Ebitda margin of nearly 30% and compound annual sales growth of more than 16% over the last three years leave little room for improvement. A goal of a high single-digit return on invested capital in year five for the Exotic Metals deal isn't terribly impressive to begin with; the risk is, even that is optimistic." New Product !

This high accuracy vise has been specially designed to prevent workpiece lift and is ideally suited for single station vise applications in CNC machining centers. On Vertical Machine Centers it has 2 operating positions: Upright & Lay Down. On Horizontal Machine Centers it has one operating position: Horizontal. Only $837 while supplies last Please call for your nearest authorized Sowa distributor (440) 463-3970 |

AuthorWe've compiled the latest news and technical information about our principals and our market that we hope you find informative! Archives

June 2024

Categories

All

|

|

Browne & Co., Inc.

9605 Tanager Drive Chardon, Ohio 44024 |

© 2024 Browne & Co., Inc. All Rights Reserved

web design by Rapid Production Marketing |

RSS Feed

RSS Feed