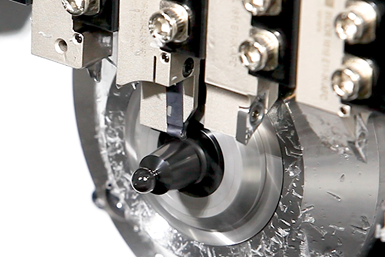

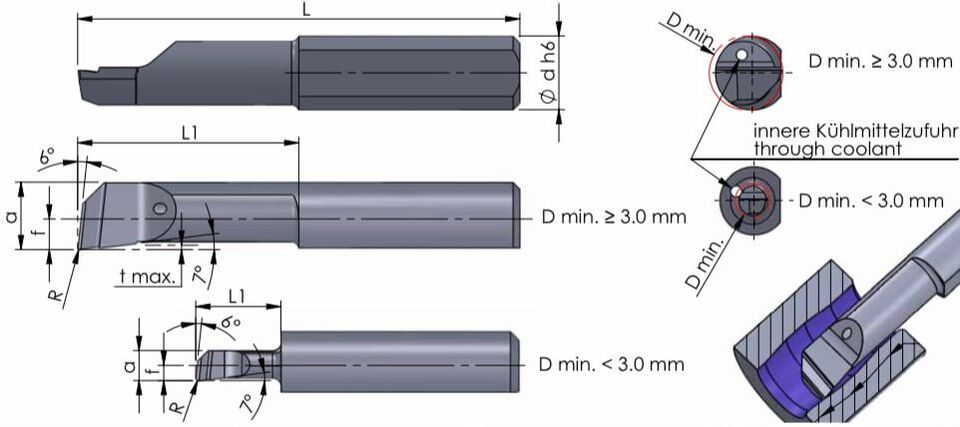

This coolant-through tooling system replacement for the gang plate on a Swiss-type machine can save hours of spindle downtime per day as well as increase tool life and enhance chip control.

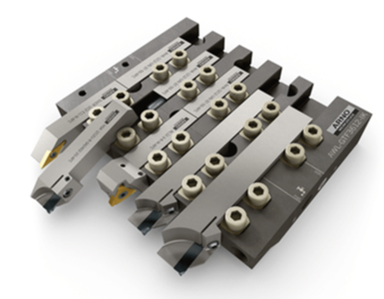

| To optimize this tool change process, Arno-Werkzeuge USA LLC has developed a coolant-through fast change tooling system that eliminates the high-pressure coolant lines in a Swiss-type’s compact workzone. The company says it also significantly decreases tool change downtime as well as setup time from hours to minutes while offering accurate repeatability. These advantages not only increase finished part output but also save thousands of dollars per spindle per year, according to the company. |

The tooling system only needs to be plumbed once and, according to the company, after that, a high-pressure coolant line should not need to be touched again. With proper setup, the high-pressure lines are moved behind the machine guards, creating a clean machining environment. This enables operators to complete safer routine maintenance. Also, the AFC’s low-profile clamps do not collect as many chips compared with a typical clamping system.

When replacing a split-shank tool, the operator simply loosens two clamps to remove the cutting head and then replaces it with a new one, the company says.

Simple, Quick Functionality

A Time and Money Saver

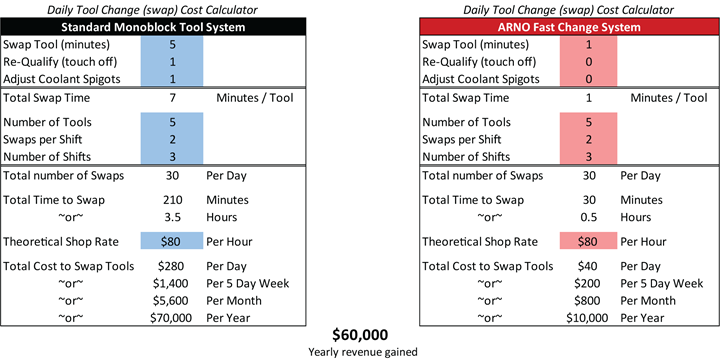

| “Then, when you scale that up to a three-shift operation, you will change tools in all five stations twice per shift,” explains Keith Stroup, business development manager at Arno. “So, 10 tool changes per shift on all five stations twice per shift equals 30 times that spindle will be idle at seven minutes each.” He figures that is three and half hours, or nearly half a shift of idle time, just to service the tools in that traditional manifold and spigot platen. “Three and a half hours every 24-hour cycle equates to $70,000 per year of spindle downtime to service the tooling in that gang plate,” he adds. |

It is also not necessary to factor in the clearing away of chips because those surfaces have mostly been eliminated with the smooth AFC design, according to Stroup. Therefore, the 17-second tool change time is the only time to factor in.

But, for a real-world example, he increases the time to one minute to consider a distracted operator that might use extra seconds

Although there are still 30 idle times per day, there are now only 30 minutes of downtime per day instead of 210 minutes using the traditional gang plate. “That only costs $10,000 per year, which means you’ve just made $60,000 a year on that one spindle by adopting the AFC system,” Stroup says.

RSS Feed

RSS Feed