|

Our last post about Lexington Cutter Offers h6 Shank Reamers prompted some questions regarding what exactly is an"h" tolerance, so this post should help you understand it a bit more.

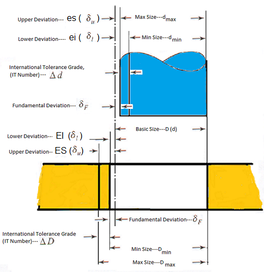

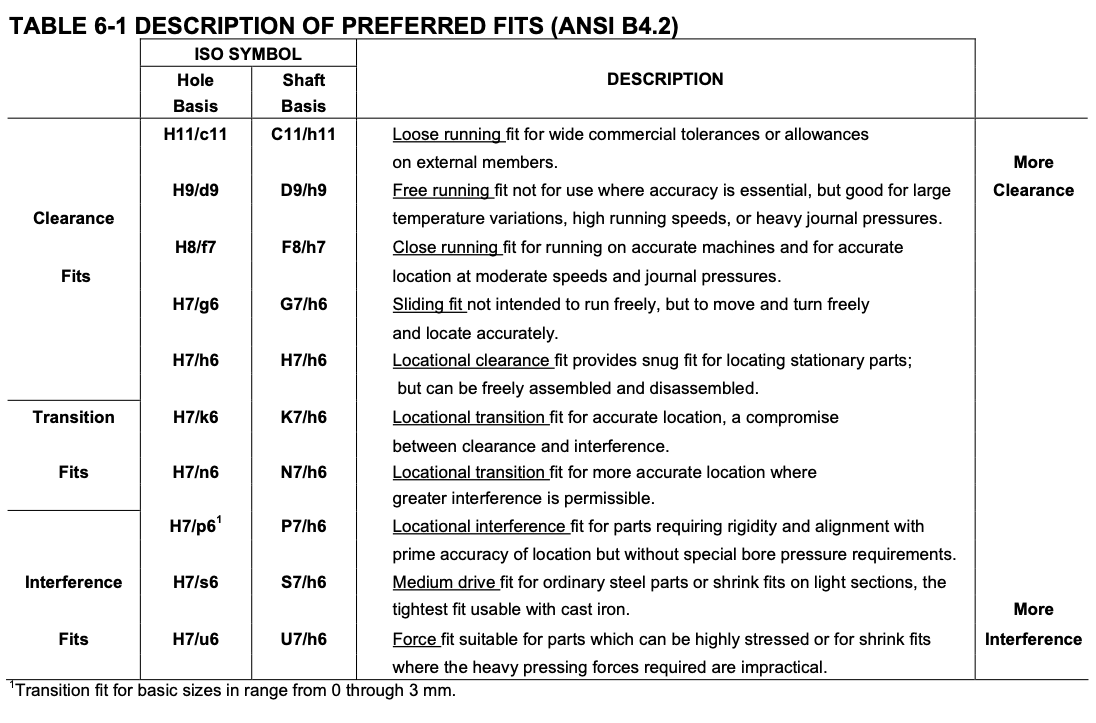

"The ISO System of Limits and Fits is a coordinated system of hole and shaft tolerances for engineering and manufacturing used for cutting tools, material stock, gages, etc. If held to these tolerances, cutting tools, material stock, and gages are available throughout the world"1 ISO and ANSI both group fits into three categories: clearance, location or transition, and interference. Within each category are several codes to define the size limits of the hole or shaft - the combination of which determines the type of fit.2 Upper vs Lower Case The tolerance symbol is established by combining the IT grade number and position letter for tolerance. The first thing to understand is the difference between a capitol "H" and a lower case "h". The upper case "H" is used to designate bore tolerance while the lower case "h" is used to designate shaft tolerances. Tolerances with lower case “h” are (minus) negative. Said another way, the capital letter "H" is for the hole, and lower case letter "h" is for the for shaft. The Number The number following the letter "h" denotes the International Tolerance (IT) grade. So, a tolerance with the number 6 will have a larger tolerance range than the number 5 but a smaller tolerance range than the number 7. This range is based on the size of the shank. A hole that has a 0.030” diameter will have an h6 tolerance of (+0.0000,-0.0002), while a 1.00” hole with have an h6 tolerance band of (+0.0000,-0.0005). Click the link below for a Shftt Tolerance Calculator. 1. Metric Standards for Worldwide Manufacturing, 2007 Edition Knut O. Kverneland

2. Shaft tolerances are now covered in the new ANSI B32.100- 2005 standard

2 Comments

North American Tool realizes how confusing the painstaking math is to get preplate part limits and a Tap “H” limit, but don’t worry, all you have to do is contact us with your thread information, and we will do the work. Call us at 800-USA-TAPS. If you want to know how it's done, we’ve included the formulas for the engineer in all of us. If you want to know how it’s done, we’ve included the formulas for the engineer in all of us. When encountering an internal threaded hole requiring it to be plated, it normally needs to be produced oversize to accommodate the plating. There are two methods for determining the correct Tap “H” limit, the “Detailed Method” and the “Simplified Method”. The “Detailed Method” requires you to do more math, but it will also determine the before plate product limits (GO & NOGO) The “Simplified Method” requires less math but will not provide you with the before plate product limits (GO & NOGO) When the plating is applied to the properly oversized threaded hole, the required thread class (2B, 3B) or special PD (pitch diameter) will be met. The effect of plating on a 60° screw thread is a change in PD of 4 times the plating thickness (2 times on each side). That is because the plating itself is parallel to the thread flanks, and the PD is measured perpendicular to the thread axis. As an example, a .0002 plating thickness X 4 results in a PD increase of .0008 (The ratio of 4:1 is for 60° threads only, the ratio for other thread forms such as ACME, 29° is different.) Detailed MethodBefore determining the tap size (H limit), it is necessary to determine the oversize part thread limits first. Once this is achieved, the tap limit is normally position at 40% of the before plate limits. Unfortunately, life is not always easy. The required plating thickness on the print, purchase order, etc. will be expressed in one of two ways, a “Maximum and Minimum Thickness” or a “One Value Thickness” requiring two different ways to calculate the oversize part thread limits. Maximum and Minimum Plating Thickness 1. The Minimum part PD (pitch diameter) is larger by 4 X the Maximum plating thickness 2. The Maximum part PD (pitch diameter) is larger by 4 x the Minimum plating thickness 3. The Tap “H” = a PD that is located at 40% of the before plate limits – minimum after plate limit \ .0005 (“H” limit increment). Selecting the closes “H” limit Example: 1/4-20 UNC-2B, plating thickness, .0002 to .0003 (1/4-20 UNC-2B after plate PD = .2175 – .2224) 1. GO Minimum before coating part PD (pitch diameter) =.2175 (after plate GO or minimum PD) + .0012 (4 X .0003 max plating thickness) = .2187 2. NOGO Maximum before coating part PD (pitch diameter) = .2224 (after plate NOGO or maximum PD) + .0008 (4 X .0002 min plating thickness) = .2232 3. Tap ‘H” Limit .2232 (Maximum before coating part PD) – .2187 (Minimum before coating part PD) = .0045 .0045 X 40% = .0018 .0018 + 2187 (Minimum before coating part PD) = .2205 .2205 (before plate Tap PD) – .2175 (after plate or minimum PD) = .003 0.003 / .0005 (“H” limit increment) = H6 One Value Plating Thickness When a “One Value Plating Thickness” is shown, we establish a maximum and minimum plating thickness values to compute the maximum and minimum before platting thread limits. This is done by assuming that the tolerance on the plating is 50% larger than the “One Value Plating Thickness.” The maximum plating thickness is 6 X, the “One Value Plating Thickness,” and the minimum plating thickness is the same as the “One Value Plating Thickness.” 1. The Minimum part PD (pitch diameter) is larger by 6 X the “One Value Plating Thickness” 2. The Maximum part PD (pitch diameter) is larger by 4 x the “One Value Plating Thickness” 3. The Tap “H” = a PD that is located at 40% of the before plate limits – minimum after plate limit \ .0005 (“H” limit increment). Selecting the closes “H” limit Example: 1/4-20 UNC-2B, plating thickness, .0003 (1/4-20 UNC-2B after plate PD = .2175 – .2224) 1. GO Minimum before coating part PD (pitch diameter) =.2175 (after plate GO or minimum PD) + .0018 (6 X .0003 “One Value Plating Thickness”) = .2193 2. NOGO Maximum before coating part PD (pitch diameter) = .2224 (after plate NOGO or maximum PD) + .0012 (4 X .0003 “One Value Plating Thickness”) = .2236 3. Tap ‘H” Limit .2236 (Maximum before coating part PD) – .2193 (Minimum before coating part PD) = .0043 .0043 X 40% = .00172 .00172 + .2193 (Minimum before coating part PD) = .2210 .2210 (before plate Tap PD) – .2175 (after plate or minimum PD) = .0035 0.0035 / .0005 (“H” limit increment) = H7 Simplified MethodThis method requires knowing what tap “H” limit that is recommended for the thread class of fit (2B 3B etc.) after plating.

Example: The recommended “H” limit for a 1/4 – 20 UNC 2B would be GH5 and for a 3B it would be GH3. Maximum and Minimum Plating Thickness When the plating thickness requirement is given with a maximum and minimum limit you would simply, Example: 1/4-20 UNC-2B, plating thickness, .0002 to .0003 (1/4-20 UNC-2B after plate recommended “H” limit GH5) One Value Plating Thickness When the plating thickness requirement is given with a one value plating thickness limit you would simply, Multiply the plating thickness by 4 (the 60° size change ratio) to determine the PD (pitch diameter) size change in inches. Then divide the PD size change in inches by .0005 (“H” limit increment). The result would be the increase in “H” limit and added to the recommended “H” limit for the required after plate thread class. Example: 1/4-20 UNC-2B, plating thickness, .0003 (1/4-20 UNC-2B after plate recommended “H” limit GH5) .0003 X 4 = .0012 (PD size change in inches) .0012 / .0005 = 2.4 (PD size change in “H” limits) rounder to the closest “H” limit = 2 Recommended “H” limit of GH5 (recommended “H” limit for Class 2B) + 2 = GH7 (pre-plate “H” limit) |

AuthorWe've compiled the latest news and technical information about our principals and our market that we hope you find informative! Archives

June 2024

Categories

All

|

|

Browne & Co., Inc.

9605 Tanager Drive Chardon, Ohio 44024 |

© 2024 Browne & Co., Inc. All Rights Reserved

web design by Rapid Production Marketing |

RSS Feed

RSS Feed