|

written, compiled and edited by Bernard Martin Class of fit for a cutting tap refers to the specific tolerance or fit that is desired between the threads of the tap and the threads of the hole it is being used to create. In other words, it defines how tightly or loosely the threads should mesh together. The class of fit is typically expressed using a combination of letters and numbers. The most commonly used standards for class of fit are the Unified Thread Standard (UTS) and the ISO metric thread standard. In the UTS, the class of fit is denoted by a combination of a letter and a number, such as 2B, 3A, etc. In the ISO metric thread standard, it is represented by a combination of a letter and a number, such as 6g, 4h, etc. For cutting taps, the class of fit is usually specified based on the intended application and the level of precision required. The class of fit can affect factors like the ease of assembly, the strength of the threaded connection, and the ability to engage the threads smoothly during tapping. A classification system exists for ease of manufacture and interchangeability of fabricated threaded items. Most, but certainly not all, threaded items are made to a UTS classification standard. This system is analogous to the fits used with assembled parts.

The letter suffix "A" or "B" denotes whether the threads are external or internal, respectively. Classes 1A, 2A, 3A apply to external threads; Classes 1B, 2B, 3B apply to internal threads Here are some common classes of fit for cutting taps:

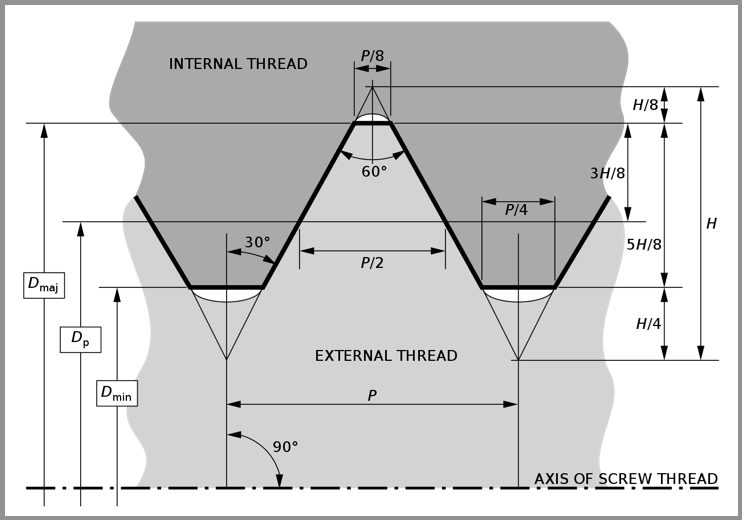

The standard designation for a UTS thread is a number indicating the nominal (major) diameter of the thread, followed by the pitch measured in threads per inch. For diameters smaller than 1⁄4 inch, the diameter is indicated by an integer number defined in the standard; for all other diameters, the inch figure is given.

This number pair is optionally followed by the letters UNC, UNF or UNEF (Unified) if the diameter-pitch combination is from the coarse, fine, or extra fineseries, and may also be followed by a tolerance class. Example: #6-32 UNC 2B (major diameter: 0.1380 inch, pitch: 32 tpi)

0 Comments

Browne & Co has been appointed as Regaional Managers for Regal Cutting Tools. They will be responsibilve for distributor and technical support for the Kentucky, Ohio, and Western Pennsylvania market areas. Regal Cutting Tools has been manufacturing world-class cutting tools since 1955 Regal offers a high performance SuperTuf series of taps for the demanding difficult to machine materials. Regal also manufactures special taps from blanks with as little as 24 hour notice.

According to Dave Browne, President of Browne & Co, "Regal Cutting Tools. is a well established and trusted brand within the metalcutting industry. Their full line of taps as well as their tap specials capabilities really compliment our product mix and fills an area we have pretty deep experience in but didn't have a product to recommend. We're really looking forward to working with our customers and running these tools!" This is Part 2 of our series on Carbide taps. Be sure to check out Part 1 if you missed it: Carbide Taps: A Practical User’s Guide to When, What, How and Why Carbide taps have a lot of advantages, especially when you’re cutting very abrasive materials. The absolute best choice for tapping glass-filled polycarbonates, space age alloys, nonferrous materials, cast iron, and a range of other exotic materials, their anti-friction qualities lead to a longer tool life.

Standard Screw Thread Insert Taps S.T.I. (Screw Thread Insert) Taps are special taps for helical coil wire screw thread inserts, which provide positive means for protecting and strengthening tapped threads in any material. Typically used on softer abrasive materials, these taps create more accurate thread forms than other standard taps. When you need to be precise, these carbide taps are the best choice. STI taps are correctly sized to produce an internal thread that accommodates a helical coil wire screw thread insert. The insert, in turn, will accept a screw thread of the nominal size and pitch at final assembly. Screw thread inserts provide stronger tapped threads (stronger assemblies) due to a more balanced distribution of loads throughout the length of thread engagement. Thread Forming Tap  Roll Taps (aka, Thread forming taps, Form taps0 offer improved thread quality and strength due to the fluteless design, and therefore allows for greater fastener strength in the threaded product. This tap does not cut, so it is “chipless,” and therefore will not cause a chip problem. This is why thread forming, over thread cutting, eliminates costly and time-consuming chip clean-up and disposal. Thread forming taps are fluteless and include lubrication grooves. Not intended for general applications, they work by displacing the metal without removing it. Because of this, they are ideal for chip removal in blind holes. Roll Thread Forming Taps Features

Carbide Insert Taps A cost-efficient solution, only the cutting portion of insert taps is made from carbide. Their HSS body is able to absorb vibration and account for their lack of rigidity. If you’re considering testing the waters with carbide taps, insert taps are a great option. It's a very economical way to utilize the benefits of carbide with solid carbide cutting face inserts meticulously brazed to a H.S.S. tap body. Carbide Insert Tap Features

Highly abrasive materials like cast iron, polymers, glass filled polycarbonates, and some cast aluminum are called “hard” materials for a reason. They’re hard to machine, hard on tool life and hard on production cycle times. How do you overcome the difficulties of making parts out of challenging raw stock? By using a tool that’s even tougher. Consider a change from steel taps to carbide taps.

We offer carbide taps in UN and Metric sizes as well as straight and NPT/F Pipe and STI Standards. A wide range of styles and features are available, including straight flute, spiral flute, spiral point, and forming taps. For increased performance and life, we can customize tools with a full line of surface coatings such as TiN, TiCN, and TiALN. How to Use Carbide TapsMachining with carbide does come with some “do’s and don’t”. Hand tapping is generally not recommended. Rigid tapping and spot-on alignment are critical to avoid breakage. Not to worry, however. Modern CNC equipment is ideally suited for carbide applications. Here’s some additional tips. Coolant holes through the taps are an option for flushing chips out of the holes on the most difficult materials like some of the tougher stainless steels and space-age alloys. Carbide STI (Screw Thread Insert) tapping of these materials has become commonplace in the aeronautical and aerospace industries. The Why of Carbide TapsAlthough initially more expensive than HSS taps, significant savings can be realized, especially in long-run jobs. Higher cutting speeds, greater tool life, and reduced downtime from fewer tooling changes translate into reduced machining costs.

An alternative to costly larger sizes is our line of CarbISert® Taps. Solid carbide cutting surfaces are bonded onto a high-speed steel body to provide the best of both worlds; durability of carbide with the “forgiveness” of a steel body and shank. So, don’t let difficult materials give you a “hard” time. Contact us anytime and put our carbide taps to work for you. Watch for Part 2 of this series on carbide taps! Coming in August 2021: The Different Types of Carbide Taps and When to Use Them Almost a year ago, Allen Benjamin, which has been a part of North American Tool, was purchased by GWS Tool Group. GWS Tool Group is a US-based, vertically integrated manufacturer of highly engineered custom, standard, and modified standard cutting tools, primarily servicing the aerospace and defense, power generation, automotive and medical sectors. GWS Tool Group has acquired multiple businesses in the course of its growth which now serves as the respective manufacturing divisions for the Company.

Just because there is a new owner, doesn't mean that the quality of an Allen Benjamin Tap has changed! If you’re in the market for high tensile strength carbide taps and metric taps, we can assure you that you’re in the right place. Not only is Allen Benjamin a leading supplier of the industry’s most durable, longest lasting carbide taps, we offer our customers the convenience of ordering online. In this day and age, we believe that quick access and top-notch customer services are critical. In today’s post, we’re going to look at why it is beneficial to order your carbide taps from Allen Benjamin. Quality Allen Benjamin carbide taps are highly efficient when tapping abrasive metals such as aluminum, non-ferrous metals, and exotic materials. With a much higher tensile strength than standard taps, their high-quality carbide taps can withstand the rigorous demands of your application. Selection Allen Benjamin offers a staggering range of carbide taps, metric taps, HSSE taps, tapping fluid, extensions, and more. If it’s taps that you are looking for, you can be confident that they’ve got them and have them ready for delivery. Service Allen Benjamin guarantees that all of their products will be the absolute best quality, within standard tolerances and dimensions, and consistent with application specifications. If their goods don’t meet your needs, you can contact us for a return authorization. At Allen Benjamin, they take pride in offering the industry’s best taps. But, more importantly, they aim to provide our customers with access to a simpler, faster way to order their operation’s critical parts, supplies, and components. If you’ve been searching for a supplier that will meet your needs and rise to meet your challenges contact us today! If you’re cutting extremely abrasive material, we’re confident that you’ve already investigated the benefits of carbide taps. Whether you’re tapping cast aluminum, nonferrous materials, polymers, cast iron, or any number of other materials, carbide taps offer better edge wear resistance and, more importantly, help to reduce downtime and increase profitability. As an ISO 9001:2008 registered manufacturer, Allen Benjamin is absolutely committed to offering the best taps on the market. In today’s post, we’re going to look at a few of the benefits of using our carbide and high-performance taps. Stronger Ideal for very abrasive metals, carbide taps have a much higher tensile strength than standard taps. Because of this, they offer a longer tool life and work to reduce production costs. Better performance Due to their ability to increase tool life, carbide taps have a positive effect on your operation’s performance. Helping you to reduce maintenance and – by extension – downtime, they allow your staff to focus on more productive, more profitable tasks. Cost-effective While the initial cost may be higher than standard taps, carbide taps are far more cost-efficient in the long run. Their extended tool life results in fewer replacements which, of course, leads to less reorders and money saved over time. At Allen Benjamin, we are steadfastly dedicated to our customers’ productivity. Always aiming to offer products that are capable of reducing maintenance, increasing uptime, and improving profitability, we strive to act as a convenient, responsive supplier of high-quality carbide taps. Whether you’re a small, local manufacturer in need of a handful of taps or a large, multi-national operation looking to place a large order, you can be confident that we can help. If you have any questions about our products, we encourage you to reach out to us today to discuss your needs! Carbide Taps From Allen BenjaminAllen Benjamin’s carbide taps provide a substantial increase in performance and tool life over HSS – or high speed steel – taps. As a result, our customers experience longer tool life and, due to this, reduced production costs that help to contribute to higher profits and a more efficient line.

|

AuthorWe've compiled the latest news and technical information about our principals and our market that we hope you find informative! Archives

June 2024

Categories

All

|

|

Browne & Co., Inc.

9605 Tanager Drive Chardon, Ohio 44024 |

© 2024 Browne & Co., Inc. All Rights Reserved

web design by Rapid Production Marketing |

RSS Feed

RSS Feed