|

Looking for an end mill with unsurpassed performance in high-efficiency milling of Titanium? The new Fullerton 3116 TiMill end mill may be just what you need. Titanium is half the weight of steel and twice the strength of aluminum: It's a high strength, light weight material with excellent fatigue performance, super durable in high stress environments and corrosion resistant.  As a result of titanium's material properties it's making it become evermore popular in the aerospace, defense, shipbuilding, medical adn dental industries. It's also what makes it considered a "more difficult to machine" material. Let's dig into that a bit more. Generally, titanium grades 1 through 4 are considered commercially pure titanium with varying requirements on ultimate tensile strength while Grade 5 is what is most often seen in the machining industry. It's often alloyed with 6% aluminum and 4% vanadium. This is what is commonly known as 6Al4V or Ti 6-4. Also quite common is 4Al4V or Ti 4-4. Why difficult? Well, first it has low Young’s modulus meaning that is more elastic than other materails: It's "gummy" which often causes spring back and chatter during machining and can readily generate long stringy chips if you don't have the correct edge prep. On top that, it's also prone to work hardening and galling super easily. You've got to keep the cutter in-the-cut: Insert cutters just aren't as good as solid endmills at doing this. Next, titanium does not have good thermal conduction properties like aluminum. Instead of heat being evacuated in the chips or transferred to the base material, heat tends to be transferred to the cutting tool which reduces it's tool life. Heat kills. Tool life declines. The right coating helps. The final icing on the cake is that titanium is prone to work hardening. During uniaxial loading, the initial rate of hardening is higher in compression so if you come back for another pass you need to get under the work hardened layer, that is, leave enough material for a finish pass to get under the layer or your tool life will suffer and your part finishes will decline with it. Ideally, finish to size in the final pass if you can. The trick to machining titanium has always been to keep consistent coolant flow to evacuate the chips and maintain a consistent chip load. Again, rough to your finish size. Don't let it work harden. That's what we've learned about titanium over the past couple of decades. There has been a ton of research on titanium's properties and that research has led to further refinement of the cutting tool geometry at Fullerton. The design of Fullerton's 3116 TiMill is based upon over a decade of aerospace testing and development and addresses many of the machining issues that Titanium presents. It's a 6-flute tool built with a 38°helix. The increased number of flutes allows for the tools to remain "in the cut" longer and more consistently. It doesn't induce as much heat as a lower number of flutes tends to do. instead, it's consistent. The 38°helix evacuates the chip at a more optimum angle than a 35°, 37.5° or 40° helix that predecessors made by competitors have tried.

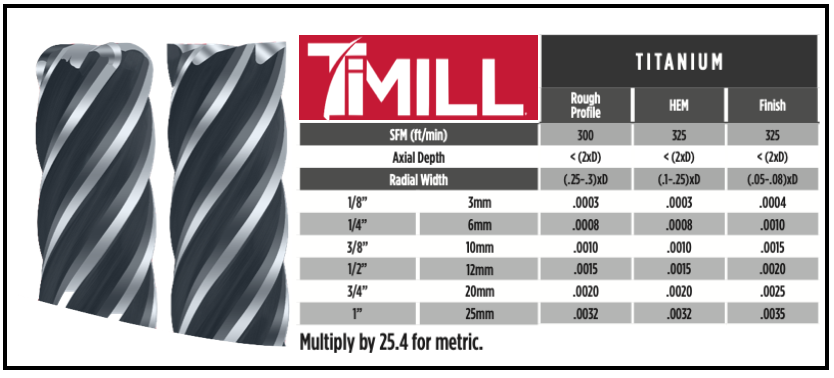

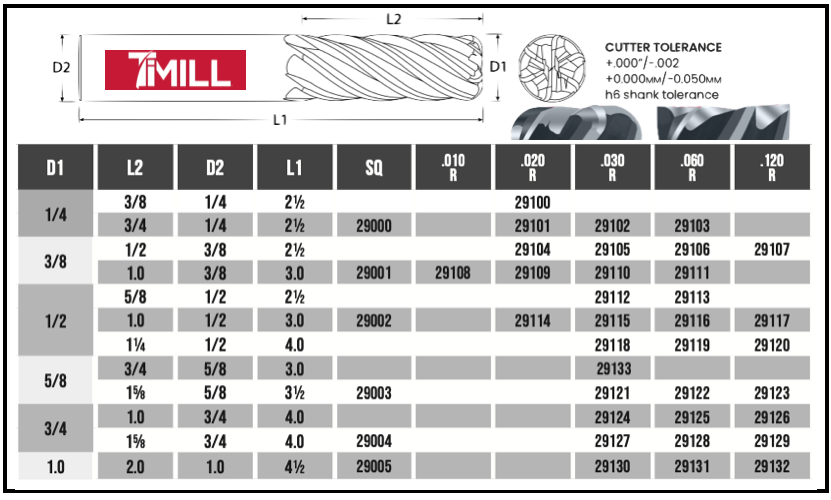

Speeds and Feeds are Critical* IT'S MADE FOR TITANIUM! So that means it is NOT Recommended for High Si Aluminum (>10%), Low Si Aluminum (<10%), Composites, Plastics, Brass & Copper, or Graphite. NOT Recommended! Choose your Size

0 Comments

Leave a Reply. |

AuthorWe've compiled the latest news and technical information about our principals and our market that we hope you find informative! Archives

June 2024

Categories

All

|

|

Browne & Co., Inc.

9605 Tanager Drive Chardon, Ohio 44024 |

© 2024 Browne & Co., Inc. All Rights Reserved

web design by Rapid Production Marketing |

RSS Feed

RSS Feed