General Purpose End Mills

Benefits of General Purpose End Mills:

- Lower prices

- Very versatile - they work in a variety of materials and applications

- Typically easier to resharpen - general-purpose end mills can usually be resharpened by the user or by a local regrind shop, whereas a high-performance end mill typically will need to be sent back to the OEM for resharpening

High-Performance End Mills

Benefits of High-Performance End Mills:

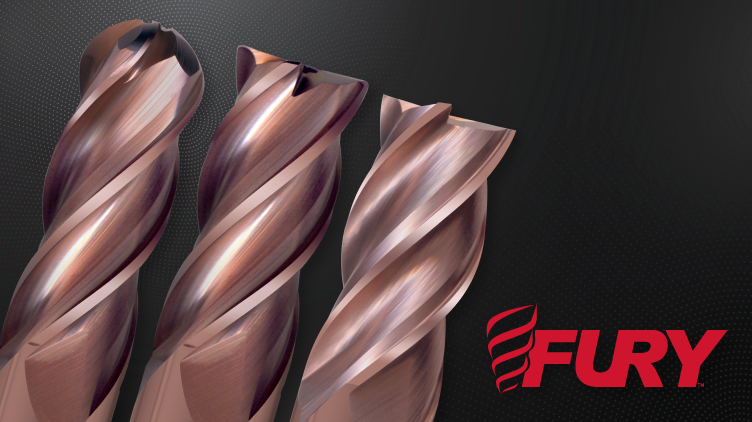

- Material and/or application-specific - This does not mean that an HP cutter will not work in more than the listed materials or applications. For example, our Fury end mill is recommended for a wide range of materials and applications and will cut almost anything and any tool path. So don't be afraid to experiment.

- Better tool life, especially in difficult-to-machine Materials - HP cutters typically require less frequent tool changes and fewer offsets.

- More adapted to high-speed machining or other advanced milling techniques.

- Better surface finishes on your parts.

- Usually have premium coatings that target a specific range of materials.

- Typically have edge preps like hones or polishes that target a specific range of materials

If you aren't sure, you can contact your Fullerton authorized distributor to help make this decision. We will work with you to get the end results you desire with a wide variety of both GP and HP end mills available.

We even have some tooling where we apply HP coatings to GP tools to help you get the most out of your cutting tool investments. We have a huge selection of inventory items and of course, if you need a special tailored tool to your specific needs, we have engineering and application knowledge to get the most out of your cutting tool budget.

We also have resources on our website to help you navigate which tool is the best for your needs. Discover what end mills are recommended for your material and application by using the Fullerton Tool End Mill Selection Guide

You can also explore and search for tooling by material, application, or tool specs as well as

recommended speeds and feeds by series which you can access at the search button below.

RSS Feed

RSS Feed