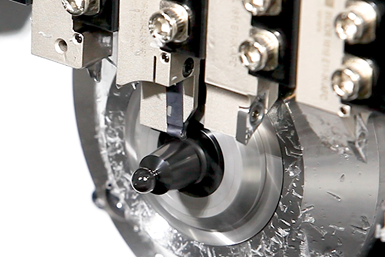

It's your solution for easy tool changes despite limited space in Swiss type machines: The two-part AFC holder – even untrained staff can replace tools fast and reliably.

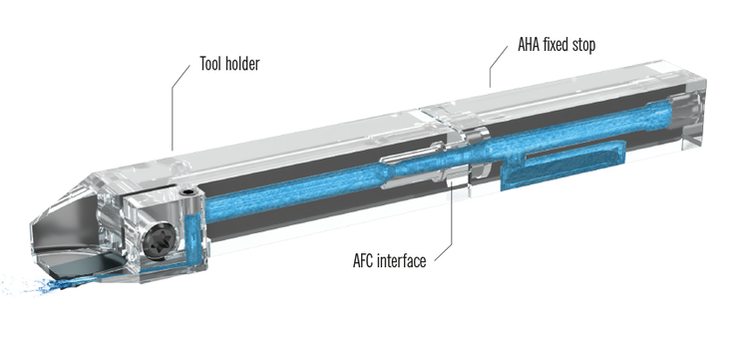

Only the front part is removed to replace the tool.

This eliminates the need to restart and recalibrate the zero point since the length to the insert tip is always the same – whether the grooving system or the turning system is used.

| When the two holder parts are plugged back together, they are immediately connected by an O-ring to prevent the tool from falling into the machine accidentally. At the same time, the floating mount provides enough clearance to compensate for angle offset. The two parts then fit together perfectly. Now you benefit from a high level of precisions when changing tools and a leak-proof coolant hole. |

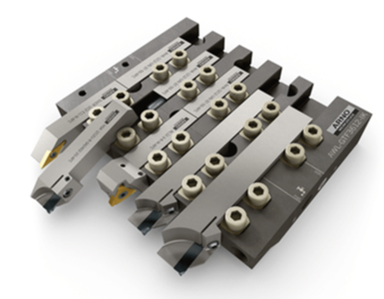

As of right now we have 51 gang plates in stock for: Citizen, STAR, Hanwha, Tsugami, KSI Swiss, DMG Mori, Nexturn and Tornos.

RSS Feed

RSS Feed