Nine 9

An Everede Company

Nine9 company began in 1994 and with the development of special tools, boring heads and accessories. The Nine9 logo was commissioned in 1999. It comes from the Chinese characters meaning “long life and durability”, words which aptly describe all Nine9 tools. 99 is the largest 2 digit number, indicating maximum product endurance.

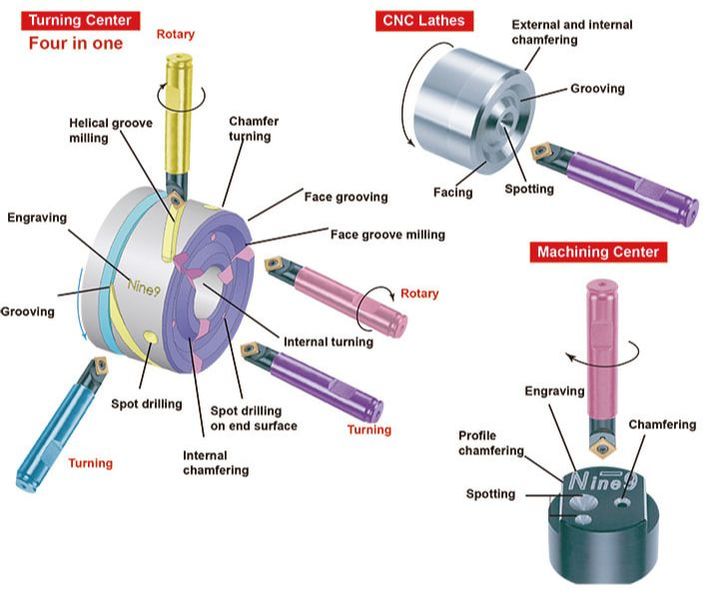

Nine9 tools are often considered ”special” in the industry, but they are standards for Nine9: NC Spot Drills, i-Center indexable center drills, Engraving tools, Chamfer Mill, Deburring Tools, Indexable drills, Boring tools, NC helix drills - helical interpolation, Power Mill. These tools have established Nine9 as a market leader and innovator in the cutting tool field.

Nine9 tools are often considered ”special” in the industry, but they are standards for Nine9: NC Spot Drills, i-Center indexable center drills, Engraving tools, Chamfer Mill, Deburring Tools, Indexable drills, Boring tools, NC helix drills - helical interpolation, Power Mill. These tools have established Nine9 as a market leader and innovator in the cutting tool field.

|

Everede Tool Company

850 West Hawthorne Lane West Chicago, IL 60185 TF: 800.621.5486 Tel: 331.871.5214 Fax: 331.240.2124 John Husar - Engineering Keith Browning - Machining |

NC Spot Drill

|

A New Drilling Concept!0.5xD of spotting

Many drill manufacturers and suppliers state that their drills start drilling on the solid material. You can look forward to the following benefits when using the NC Spot Drill to drill a spot that is half of the drilling diameter:

|

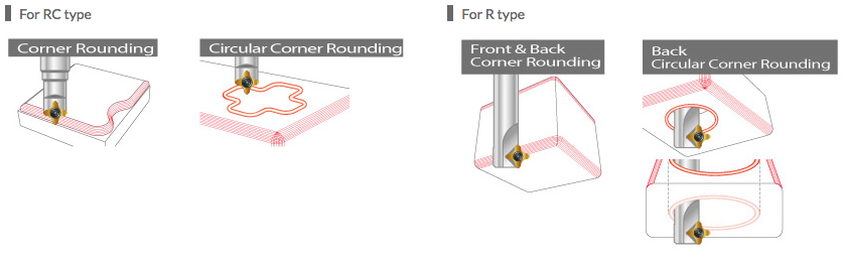

Corner Rounding

|

Corner radius 0.5mm ~ 6.0mm, indexable carbide insert, various corner radius inserts can fit on same holder. We provide R and RC types to you.

Type of RC Combination corner rounding and 45° chamfering. Very small X offset 1.25mm for radius 0.5, the small x offset allows for profiling in small corners. Each insert has 2 cutting edges. Type of R For front and back chamfering. Each insert has 4 cutting edges. |

V045 / V060 Engraving Tools

|

|

30o / 45o / 60o / 90o engraving tool with indexable carbide insert, excellent repeatability, reducing your presetting time, no resharpening required.

|