|

In January of this year we welcomed a new member to our Browne & Co. sales team and with manufacturing companies opening up again, it's about time we introduce you to Jeff Terrace!

Just before joining Browne & Co in January 2019, Jeff worked at Hoffmann Group, a German cutting tool, hand tool, workstation and storage solutions manufacturer. Jeff has been working as an InovaTool representative since February of 2019 and recently joined Browne & Company at the beginning of 2020 as our Cutting Tool Specialist. Please send Jeff and email or give him a call to introduce yourself or pick his brain about an application question.

0 Comments

In industry, hand chain and lever operated hoists are most often used as an in-plant tool for periodic maintenance applications. A typical use might be for lifting pumps, generators, valves, pipe or other heavy equipment. Whether a hoist is used in construction, maintenance, machine shops or automotive garages, hundreds of applications exist for a manual chain hoist and many thousands are sold every year. One of the largest lifting rental yards in the United States (TX) has standardized on Tuffy Hoists for their rental fleet - If they can take the rigors and abuse of rental, they can certainly stand up to anything your shop can throw at them!

Please call or email Browne & Company for your closest authorized Tuffy Hoist distributor

440-463-3970 [email protected] Greendale Wisconsin based Safeway Sling USA Inc. has been acquired by Houston-based Bishop Lifting Products Inc. The transaction closed April 2 for an undisclosed price.

“One of the reasons that this was necessary is that I know that none of us live forever and I work with some of the most wonderful people,” Susan Szymczak said. “We’ve got a number of people that have been here for 20-plus years and they have to be taken care of.”

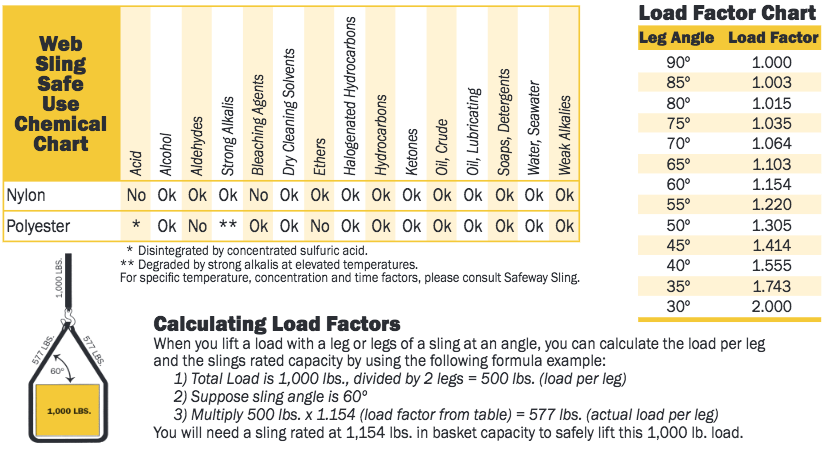

Bishop Lifting, a subsidiary of SBP Holdings, makes, distributes and rents wire rope, sling and rigging products and services. Its sister company Singer Equities makes industrial hose, conveyor belt and gasket material. Together, the companies have 1,080 employees at 61 North American locations. Bishop described Safeway as the “gold standard” for overhead lifting slings in an announcement. “We are excited with the addition of Safeway Sling to our family of companies,” said Harold King, president of Bishop. “Safeway Sling has a proven track record in our industry of supplying the highest quality synthetic slings with the highest level of service.” Susan and Jim will stay on at Safeway for three years, and Bishop has named their daughter Andrea vice president and general manager. The Greendale operations will remain in place and all of the employees will be retained in the transaction, Susan said. “They’re committed to keeping Safeway here,” she said. “We’re totally set up as a sling manufacturer. If you move the tester even one inch, it’s considered out of calibration.” Milwaukee investment bank Emory & Co. advised Safeway Sling in the transaction. “We ran a full sale process, contacting numerous strategic buyers and private equity groups, and Bishop Lifting emerged as the clear choice as the best buyer,” said John Emory Jr., president of Emory & Co. The marketing process generated 26 interested parties, Susan said. “I was surprised that there would be that many people interested in this little company,” she said. “I think the level of integrity is very high and that’s critical.” Susan said the cultural fit was ideal with Bishop, which is why Safeway ultimately chose it. “The values and the meeting of the minds is just uncanny,” she said. George Davis from Safety Service Company penned a terrific Article in 2008 titled "The Top 13 Tips for Superior Sling Safety". Portions of the below article are adapted from his original article. Material handling safety is among one of the most important tasks in any industry. Without it, important tools, equipment and materials cannot be moved, sold, manufactured and utilized. This is the very reason why slings are important tools in almost every industry. Without them, it would be difficult to handle materials and transport them from one place to another. But more often than not, loads are too heavy for the slings that support them. This results to workers getting injured or killed because loads fall on them or hit them. The same thing happens when operators are not trained in the proper use and maintenance of slings. Slings end up being out of the operator’s control or losing their strength because of abuse or wear. Performance Characteristics of Webbing

Top Tips for Sling Safety

|

AuthorWe've compiled the latest news and technical information about our principals and our market that we hope you find informative! Archives

June 2024

Categories

All

|

|

Browne & Co., Inc.

9605 Tanager Drive Chardon, Ohio 44024 |

© 2024 Browne & Co., Inc. All Rights Reserved

web design by Rapid Production Marketing |

RSS Feed

RSS Feed