This article traces the journey of how these esteemed companies became intertwined under the umbrella of Regal Cutting Tools and Besly Cutting Tools, reflecting the evolution of the cutting tool industry over the years.

Besly Cutting Tools

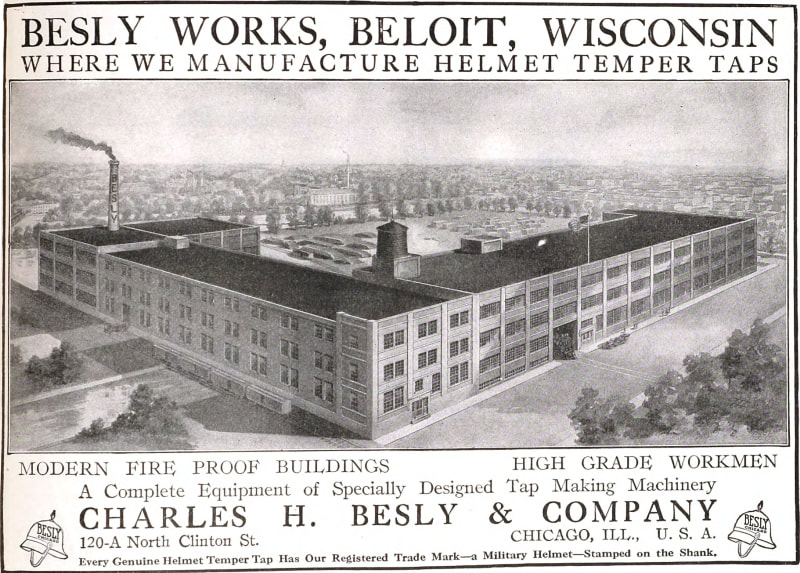

The company was founded by Charles H. Besly, who had already founded a mill supply house in Chicago in 1875. He established a one-man manufacturing plant in Beloit in a building he obtained in settlement for a customer's overdue bill.

In Beloit, Besly hired Frederick N. Gardner to turn out a variety of taps, small tools and other items to be sold through the Chicago store.

In 1891, the first disc grinding machine in America was built in the Besly plant in Beloit. At the time, the company was located on the east side of Second Street near St. Lawrence Avenue. The disc grinder went on to become a basic machine in manufacturing, and the original Besly machine is on display at the Ford Museum at Greenfield Village, Dearborn, Michigan.

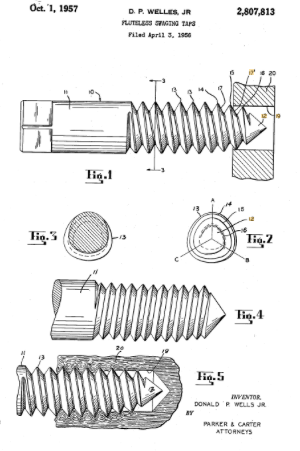

| The Besly-Welles Era Besly was purchased by the Welles family in 1936, and changed the name of company to Besly-Welles Corp. in 1952. Edward P. Welles was the company's first salesman of Besly grinders, and he rose through the ranks to be president of the company following Besly's death in 1908. Until 1950 a cutting tap was the only tool available for the creation of internal threads. In 1950 at least two manufacturers began making swaging taps. In 1957 Besly-Welles commenced marketing its improved "fluteless swaging tap" in regard to which it eventually obtained three patents. Besly-Welles earliest swaging tap patent was issued in 1957 and the final patent on August 28, 1962. Today most people call this "fluteless swaging tap" a "form tap" or a "roll tap". Besly was a part of this innovative piece of thread making history. |

Besly-Welles Corp. was sold to Bendix in 1965, and at the time was enlarged with two other Bendix affiliates, the former Threadwell Tap and Die Co. of Greenfield, Mass., and Scully-Jones and Co. of Chicago. The South Beloit facility acted as headquarters for the industrial tools division.

In September 1984 James A. Deeds, who worked as controller for the company, purchased Bendix' local plant. He changed the name to Besly Corp., and continued manufacturing and distributing cutting tools, including standard and high speed steel taps, drills, reamers, end mills and carbide tipped cutting tools.

In November of 2005 a new company, Besly Cutting Tools, Inc. was established with plans to continue customer service, technical support, inventory, shipping and manufacturing in South Beloit.

In 2005 Besly Cutting Tools, Inc. was acquired by YG-1.

The Beloit Tool Company

| In 1955, Beloit Tool Company started in a vacant roller rink. Similar to other earlier entrepreneurs, the founders saw an opportunity to build a business based on the need of manufacturing companies. Many of these companies required rapid service when they were developing a product with special threads. |

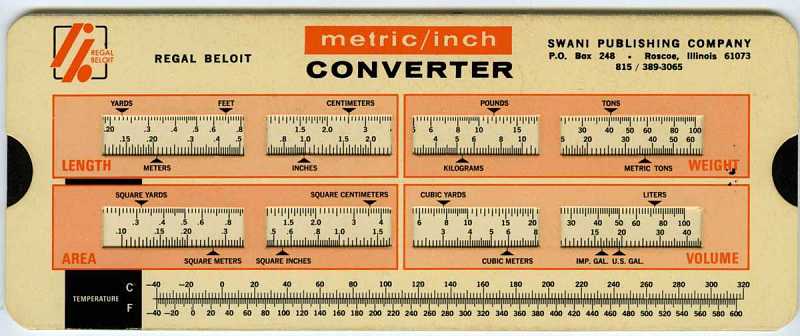

| The company quickly expanded due to its philosophy of fast response times to phone calls, requests for quotations, quick shipments and quality tools.. 24 hour shipment of special taps often resulted in long work days—meaning employees often had to shift work schedules in order for these shipments to be accommodated. Beloit Tool became Regal Beloit in 1969. As the company grew by acquiring other companies, the focus became power transmission equipment, and then electric motors shortly afterwards. The cutting tool operations, though the foundation of this multi-billion dollar corporation, was no longer the company’s main focus. In order to regain its original focus, the company found a buyer who would continue the legacy that was created so many years before. in 2006, YG-1, the world's third largest cutting tool manufacturer acquired the cutting tool division of Regal Beloit and it was renamed Regal Cutting Tools. |

YG-1: A Global Powerhouse in Cutting Tools

The company strategically entered the North American market with an opening of the Chicago office in 1985, marking its commitment to expansion. Notably, YG-1 made key acquisitions in North America, including the acquisition of Besly Cutting Tools, Inc. and Regal Beloit's cutting tool division in the early 200's. The acquisition of Besly in particular enhanced YG-1's capabilities and product portfolio in the North American Markets.

With the addition of Regal Beloit's cutting tool division, YG-1 strengthened its position in North America, showcasing its commitment to innovation and growth in the global market. These acquisitions allowed YG-1 to leverage the expertise and market presence of the acquired companies, contributing to its success as a prominent player in the cutting tool industry.

RSS Feed

RSS Feed