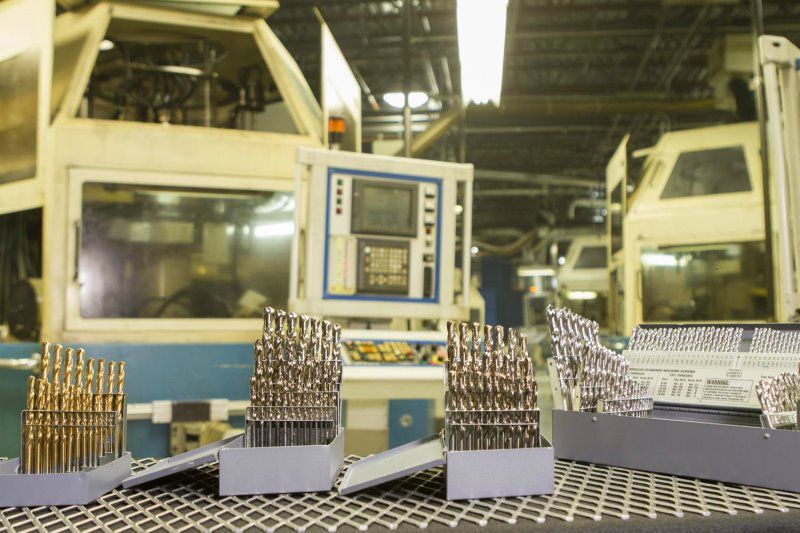

Besly Turboflute Drill sets T-715-TF

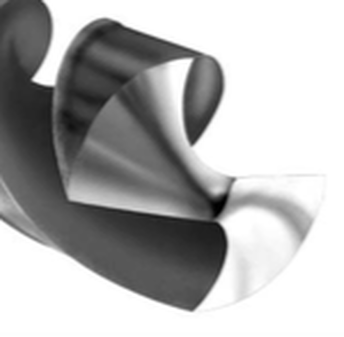

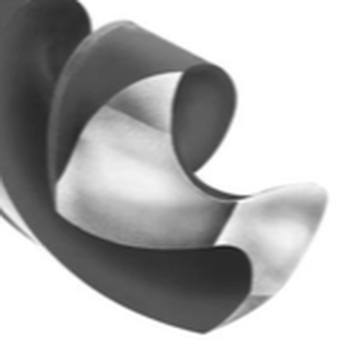

Besly Turboflute Drill sets T-715-TF Designed for automotive, aerospace, and other high volume metalworking industries, they give longer life and better drilled hole quality while allowing increased feed rates. The split point design seats itself and holds centers.

These heavier web drills are ideal for use in stringy, low and medium strength steels below 120,000 psi ultimate tensile strength, and for use in exotic and difficult-to-machine materials, ferrous and nonferrous.

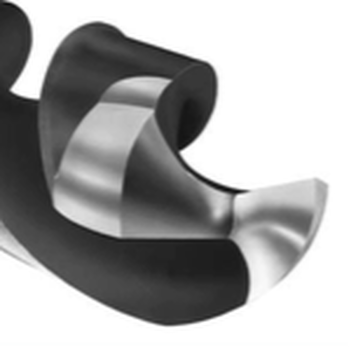

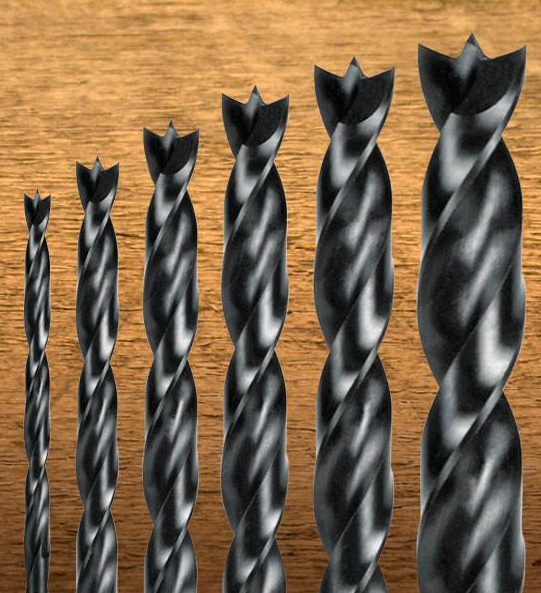

Parabolic flute drills, also known as parabolic flute twist drills, offer several advantages compared to standard twist drills with straight flutes. These advantages make them a popular choice in various drilling applications. Here are some of the key advantages of using parabolic flute drills:

- Improved chip evacuation: Parabolic flute drills have a curved or spiral flute design that helps facilitate better chip removal. As the drill bit advances into the material, it creates chips that move up and out of the hole more efficiently. This reduces the risk of chip clogging and ensures smoother drilling operations.

- Reduced friction and heat generation: The curved flute geometry of parabolic flute drills allows for a larger volume of coolant or cutting fluid to reach the cutting edges and the workpiece, helping to dissipate heat effectively. This minimizes heat buildup and reduces the risk of workpiece overheating or material deformation during drilling.

- Increased drilling speed: Parabolic flute drills are designed to cut more efficiently, thanks to their improved chip evacuation and reduced friction. This often translates to faster drilling speeds and shorter cycle times, making them ideal for applications where productivity is crucial.

- Enhanced tool life: The combination of better chip evacuation, reduced heat generation, and increased drilling speed can extend the life of the drill bit. Parabolic flute drills tend to experience less wear and damage compared to standard twist drills, leading to longer tool life and cost savings.

- Versatility: Parabolic flute drills can be used on a wide range of materials, including metals, plastics, and composites. Their ability to handle various materials makes them versatile tools suitable for different machining applications.

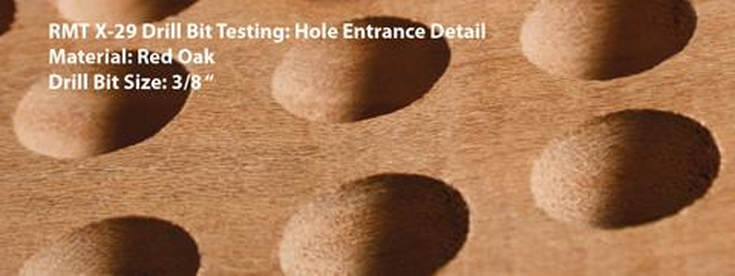

- Improved hole quality: Due to their efficient cutting action and reduced vibration, parabolic flute drills often produce cleaner and more precise holes. This is particularly important in applications where hole quality is critical.

- Lower power consumption: Because parabolic flute drills require less force to cut through materials, they can lead to reduced power consumption in drilling machines, which can result in energy savings over time.

Extra Length, Tanged, Bright Finish (Catl No T-218-TF)

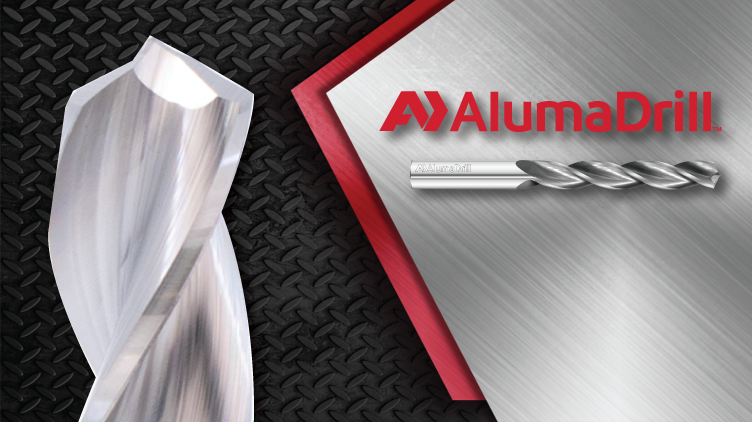

Jobbers Length, Bright Finish (Catl No T-755-TF)

The split point design seats itself and holds centers. Bright finish drills, Catl No. T-755-TF, are for use in aluminum and other nonferrous materials.

Jobbers Length, Surface Treated (Catl No T-705-TF)

Besly Turboflute Drills have heavy duty parabolic profiled flutes for easy chip flow. Designed for automotive, aerospace, and other high volume metalworking industries, they give longer life and better drilled hole quality while allowing increased feed rates.

The split point design seats itself and holds centers. Surface treated drills, Catl No. T-705-TF are intended for drilling stringy, low and medium strength steels below 120,000 psi ultimate tensile strength. Also available in sets (Catl No. T-715-TF).

RSS Feed

RSS Feed