The Hard Stuff

Exotic alloys are specifically designed for high-temperature applications (think aerospace), performance in corrosive environments (think underground), or to have the highest available strength to weight ratios (think earth-moving applications). The machinability of these materials is NOT the first consideration. As much as it would be nice from the machinist’s viewpoint to have an aluminum firewall in a helicopter, as the pilot or passenger you want a material that is strong and heat retardant.

| Unique Challenges When you’re working with exotics, it’s not just another day at the shop. On the positive side, their unique elemental compositions make them suitable for applications where traditional materials like alloyed steels or aluminum, would fail. On the other hand, some of these materials exhibit undesirable (to say the least) behaviors like igniting spontaneously when machined and exposed to the atmosphere. Also, these alloys are typically more expensive than traditional steels machined in most shops, so scrapped pieces are going to cost you big time. |

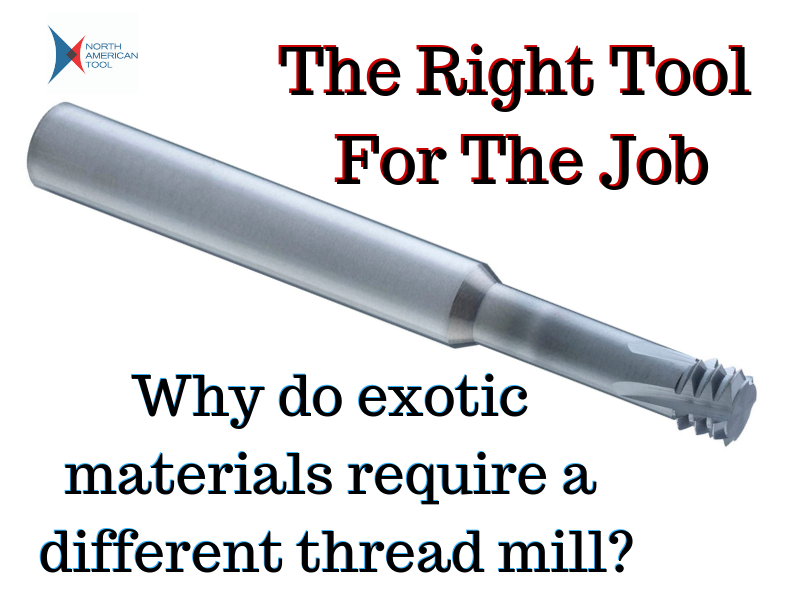

One day a new job order comes in and you are faced with threading these kinds of alloys. What’s an operator to do? Fortunately for you, North American Tool manufactures application-specific thread mills right here in the USA.

These tools are made from solid carbide and have been specially designed with exotic materials in mind. The results are longer more consistent tool life and the elimination of scrap due to tap failures in your parts.

Uniquely Crafted

North American Tool thread mills for exotic alloys are designed with only three teeth. This places less stress on the tool than a conventional thread mill with six, eight, or ten teeth engaged in the workpiece at the same time. Carbide thread mills nickel-based alloys are also made with left-hand helix and left hand-cut, which permit an operator to run from the top of the hole to the bottom and climb mill the threads.

This will create a right-hand thread on the part. The threads are milled, rather than cut, typically producing a better quality thread in the part.

The thread mills are coated with AlCrN to give them greater heat and wear resistance in the high heat, higher abrasive applications that typically confront an operator when machining exotic alloys.

Exotic Material Experts

As well as thread mills, we are the industry leader in designing and manufacturing special taps for exotic materials as well. Thread mills are a good alternative tool to the special taps we design every day provided of course, you have a 3-axis CNC capable of the interpolation tool path needed for thread mills.

If you are working with exotic materials and need a thread mill or special tap, please contact us for a quote. We’d be happy to help.

RSS Feed

RSS Feed