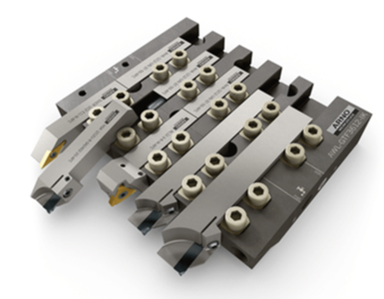

You can also find the latest high performance cutting tools displayed from Fullerton Tool, Regal Cutting Tools, Rocky Mountain Twist Drill, The Everede Family of tooling, Dapra, and others.

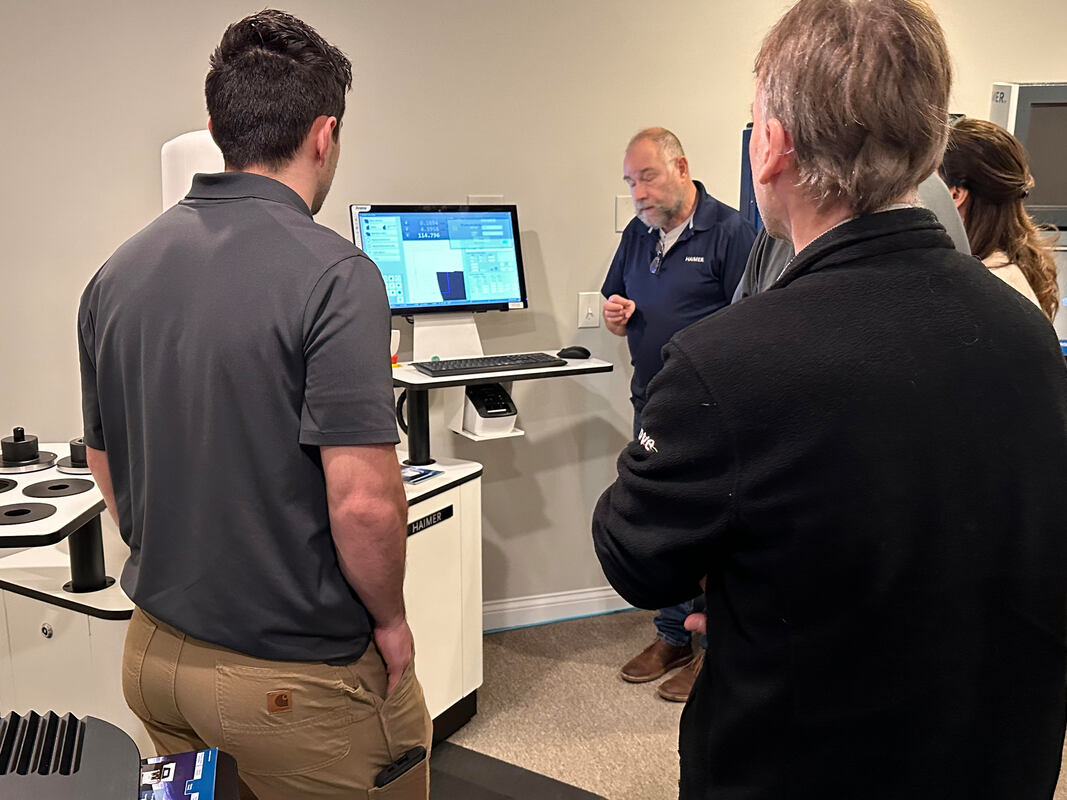

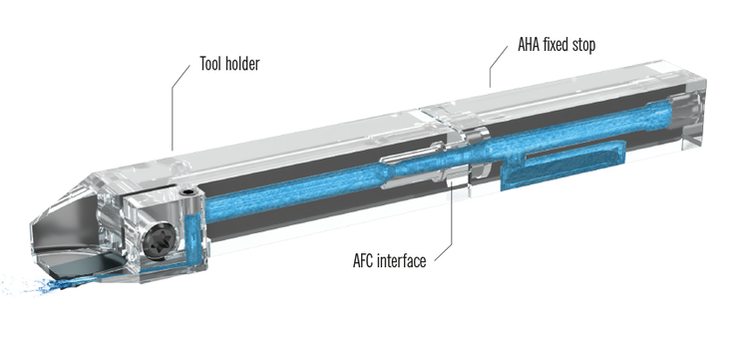

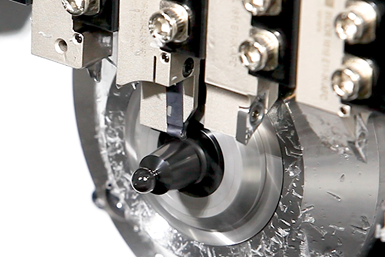

The Technology Center is designed to meet the growing demands for higher precision, efficiency, and performance in metalworking. It is equipped with the latest advancements in Haimer technology and tooling, ensuring consistent set-up, unsurpassed machining accuracy, better tool life, and improved part finishes. The center represents a significant investment in innovation and demonstrates Browne & Company's commitment to advancing the metalworking industry.

"We are excited to unveil our new Technology Center, which symbolizes our dedication to providing the best in metalworking solutions," said Dave Browne, President of Browne & Company. "This facility not only showcases the latest in technology and tooling but also serves as a hub for innovation, collaboration, and education."

Industry professionals, clients, and partners are invited to explore the capabilities of the new Technology Center and witness firsthand the advancements in metalworking technology. Browne & Company is offering personalized demonstrations to showcase the benefits and efficiencies that their state-of-the-art technology and tooling can bring to any operation.

"To see the future of metalworking, we invite you to visit our Technology Center. Our team is ready to demonstrate how our latest technologies and tooling can enhance your operations," added Browne.

Don't miss the opportunity to experience the latest in metalworking technology and innovation. Click the button below to schedule a demonstration with our team and discover how Browne & Company can elevate your metalworking projects.

Browne & Company has been at the forefront of the metalworking industry, offering innovative solutions and high-quality tooling to clients across various sectors. With a focus on precision, efficiency, and reliability, Browne & Company continues to lead the way in metalworking technology and services.

RSS Feed

RSS Feed