How to Inspect Synthetic Web Slings All of our synthetic web products are designed for long life under punishing conditions, but they will eventually wear out after extended use. The key is knowing when to replace them, and that’s why it’s very important to inspect your slings on a regular basis. We’ve developed an inspection program based on the procedure outlined in ANSI B30.9 that will make the most of your investment. It’s based on four sound beliefs:

How Often to Inspect Slings The frequency of inspection depends on three important factors:

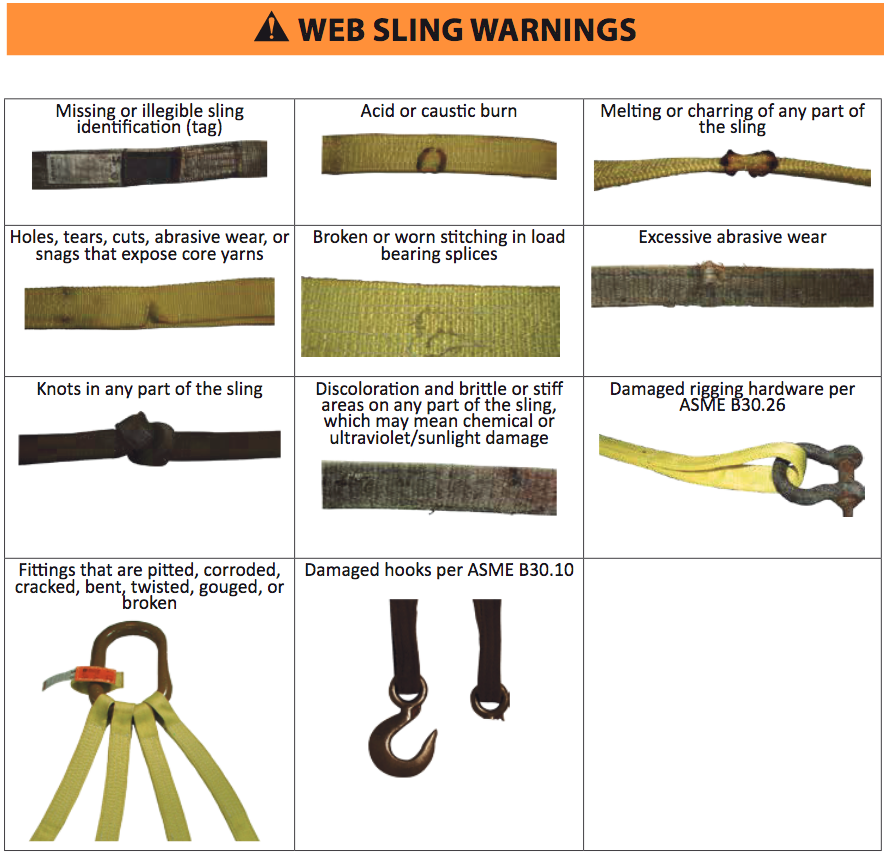

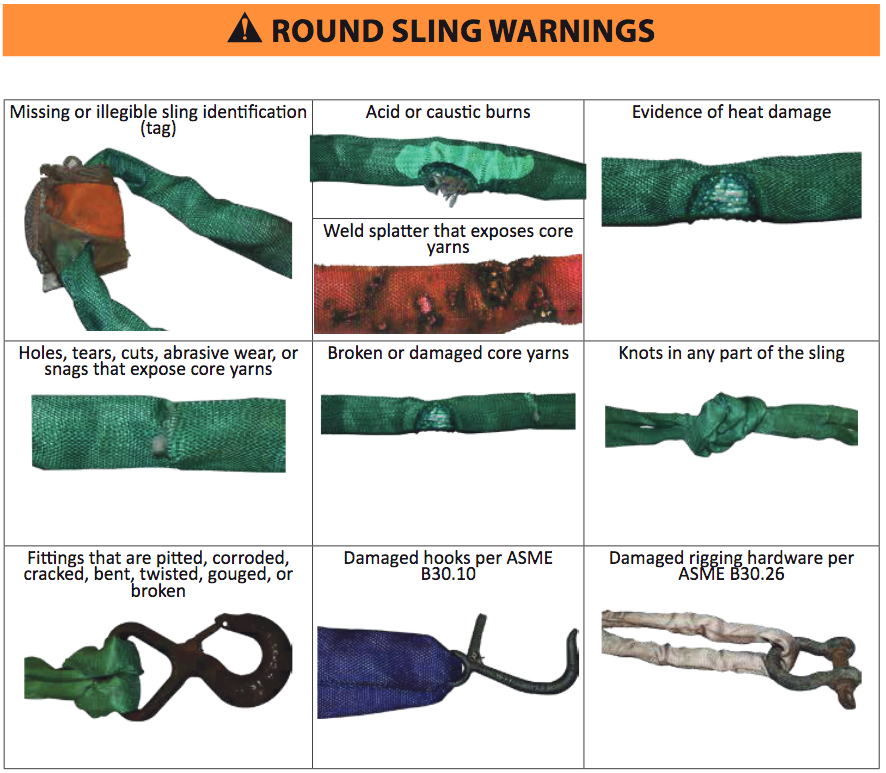

When to Replace Slings Remove all slings, including Flexi-Grip® roundslings, from service if you see damage such as the following, and return to service only when approved by a designated person. These are removal criteria established by ASME B30.9:

Identifying Wear and Abuse These are some of the most common types of web sling damage caused by abuse and misuse. When you see any of these problems during your regular inspection, stop. Replace the sling immediately because the damage is done. Never attempt to mend the sling yourself and, more so, never attempt to lift with these slings. Whether a sling is damaged from improper use or normal wear, the same rule applies in all cases: Always cut the sling eyes and discard the sling right away when you see damage. Only with properly working slings can you take a load off your mind.

1 Comment

hafiz

9/10/2020 02:22:53

about discolour by heat and raining.

Reply

Leave a Reply. |

AuthorWe've compiled the latest news and technical information about our principals and our market that we hope you find informative! Archives

June 2024

Categories

All

|

|

Browne & Co., Inc.

9605 Tanager Drive Chardon, Ohio 44024 |

© 2024 Browne & Co., Inc. All Rights Reserved

web design by Rapid Production Marketing |

RSS Feed

RSS Feed