|

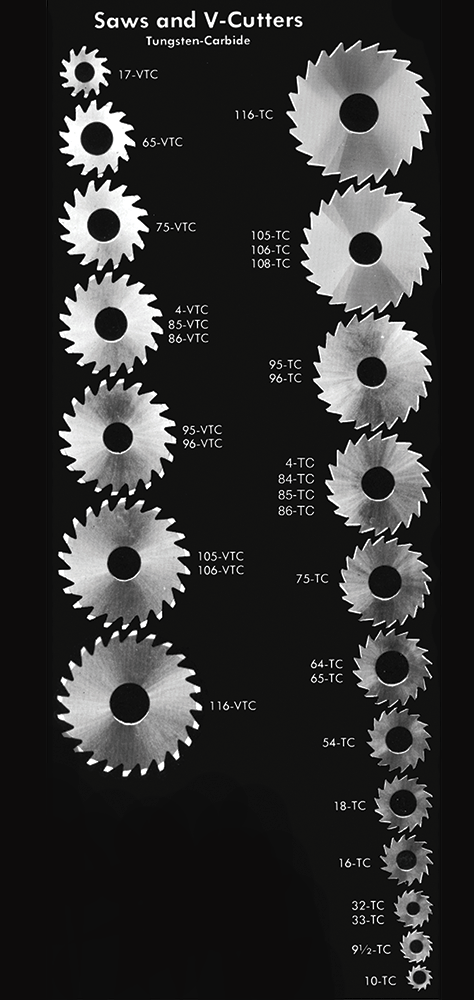

compiled & edited by Bernard Martin As more and more of our customers are using Martindale Gaylee Circular saws we put together this guide to the commonly asked questions such as "Is there a rule-of-thumb for the number of teeth?" or "How much side clearance should I have?" Here we cover a lot of the fundamentals of selecting the right circular saw blade configuration, some tips, tricks, and troubleshooting for when things go wrong. Circular Saw Feed Rates These are general cutting speed recommendations for circular saws used in metalcutting from Martindale/Gaylee. The may vary from application to application but are basically some general suggestions starting parameters when using high speed or carbide saws.

Selecting the Proper Number of Teeth in Your Metalcutting Saw Generally speaking, deep cuts and soft material require fewer teeth for chip clearance and stronger teeth (landed) Thin material requires more teeth, but keep-in-mind that at least 2 teeth on the blade need to be engaged in cut.

Rake Angles and Side Clearance AnglesSIDE CLEARANCE (Tangential Clearance Angle) This is also known as dish or hollow grind. You measure down the side of the tip and the difference it is the difference between front and back. As you cut, material it gets compressed and springs back after the cutting edge passes. A steep side clearance angle gives plenty of room for the material to expand and prevents thermal expansion of the base material. Keep in mint that a very flat side clearance angle can provide a smoother cut in some materials. For stainless steel and tenacious metals such as copper, zinc, tin or lead an increase in the side clearance is desirable as these materials tend to "spring back" (thermal expansion) on the blade. RAKE ANGLES Rake angle is the term used to describe the direction of the blade’s teeth, as referenced from the rotation and central axis of a saw blade. If you imagine a line going from the exact center of the blade to each tooth, having the front of the tooth directly on that line would be a zero degree rake angle. The rake angle of the blade is described in comparison to that imaginary line. A positive rake angle meana that the teeth are angled more towards the angle of rotation, while a negative rake angle would mean that they are angled backwards, away from the direction of rotation. Generally speaking, the preferred rake angle is:

Why do Circular Saw Blades Break? It's commonly known that when saw thickness is less than 0.125″, keyways can cause stress risers and cracks. That is why washers are often used. However, Breakage, Wobble and Rubbing problems are often caused by how the washers are mounted on either side of saw.

Remember, washers drive the saw in the absence of a drive key. They must always be clean, flat and bur-free. A speck of dirt will let saws wobble and cut oversize. If a saw breaks, it may score the washers. Always check for scoring marks around saw hole for dirt, chips or grit. Shiny spots, as small as a pinpoint, indicate that chips where imbedded under washers. Circular skid marks indicate the nut was not tight. Generally speaking:

Saw Blade Teeth most often break as a result of:

NOTE: HSS saws will turn colors as they heat during cutting. A straw color is the limit. The saw will lose its temper when it starts turning blue.

7 Comments

6/21/2021 11:38:35

My cousin is working on a project that requires him to use copper pipes of specific sizes, so he needs to make sure they're cut and shaped properly. It's great that you explain that a steep side clearance angle is a good option for copper. Maybe he should hire a professional and talk to them about the angles and blades they use to ensure they can help him get the exact shapes and sizes he needs.

Reply

12/22/2021 14:34:23

I am glad you mentioned how you should choose a blade with more teeth for hard materials so you get a smoother cut. This essentially means that you should choose the blade for your project based on what you intend on using it for. I think that it would be crucial to hire a reputable manufacturer to make the best blade for your project with the right number of teeth.

Reply

12/30/2021 20:57:53

I like your blade tips. I need to get get my circular shop saw sharpened. I'll have to consider taking it to a sharpening center.

Reply

2/13/2022 14:43:20

Cabinet saws are more substantial in overall construction than contractor saws - they're built using more cast iron and steel, have heavier trunnions, gearing, and arbor assemblies, and more powerful motors than their contractor saw counterparts. If you want to read more about best contractor table saws please visit for more<a href=https://sawpicks.com/best-contractor-table-saw/>information</a>

Reply

6/14/2022 09:47:24

You made a good point when you discussed that hard materials demand more saw blades with more teeth for a smoother cut. My friend should know this since he's planning to buy a 787 carbide-tipped steel saw blade to cut hardwood floors. I think it's best for them to contact a distributor of all types for saw blades.

Reply

9/27/2022 18:35:38

I found this article to be very informative and helpful, especially because it includes images to help explain how to select the proper number of teeth when using a metal cutting saw. This is a great resource for readers who want to learn more about metal cutting circular saws.

Reply

Thanks for pointing out that there are cutting speed recommendations when it comes to metal-cutting processes using circular saws. In that case, companies or factories have to rely on precision circular saw guides to know what type of tools they should be getting as well as their parts. Doing so will ensure that they are going to invest in the right items, especially if they might also be for the safety of the operator.

Reply

Leave a Reply. |

AuthorWe've compiled the latest news and technical information about our principals and our market that we hope you find informative! Archives

June 2024

Categories

All

|

|

Browne & Co., Inc.

9605 Tanager Drive Chardon, Ohio 44024 |

© 2024 Browne & Co., Inc. All Rights Reserved

web design by Rapid Production Marketing |

RSS Feed

RSS Feed