|

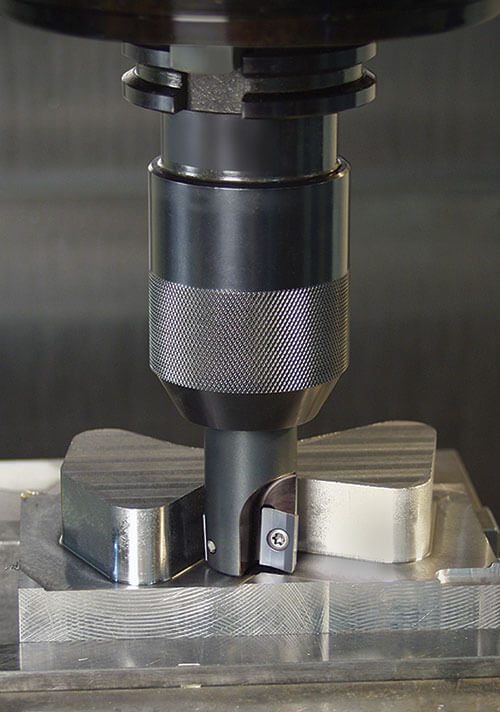

Choosing the right insert geometry and grade for an application can easily make or break a job. Making the right choice requires educating yourself on what types of cutting edge and carbide grades are best suited to the machining conditions present.

Grade SelectionDapra uses an easy-to-understand system that separates grades by toughness/hardness. The same coatings are available for each carbide substrate, so choosing the grade begins with the toughness of the substrate desired and ends with the coating of choice. For abusive applications, use of the toughest grade is recommended. These would be identified as the following: interrupted cuts; long tool lengths; poor chip evacuation; stainless steels; high-temperature alloys; poor workpiece or machine rigidity; coolant use or very heavy cut depths.

For stable, steel and ductile iron applications, Dapra recommends our medium toughness/hardness carbide. Examples of some good applications include: uninterrupted steel cuts; good workholding / machine rigidity; short tool / diameter ratios; lighter depths of cut; good chip evacuation; alloys; low and high carbon steels; ductile (long-chipping) irons; and dry machining.

For very stable, high-wear applications in cast iron and nonferrous materials, as well as hard milling of heat-treated materials, Dapra recommends the use of our hardest grades. Application examples include: gray cast irons; aluminum and copper alloys; plastics; light, smooth cuts in any material; and heat-treated steels (typically over 48 Rc).

Geometry SelectionDapra offers three different cutting edges for the Square Shoulder milling line:

General RecommendationsMaterial Being Machined Use stronger, T-land cutting edges for steels and cast irons. Use sharper honed edges for stainless steels and high-temperature alloys. For aluminum and plastics, use sharp, un-honed cutting edges. Workholding / Machine Tool Rigidity Use the recommended grades and geometries for rigid setups and machines. In cases where rigidity is lacking (light-duty machine, poor workholding, etc.), use tougher grades and stronger geometries. The exception to this rule is when the use of the sharper geometry (XPET) actually stops or reduces the vibration created by the poor rigidity. These situations typically present a "trial and error” scenario.

Long Toolholder / Length to Diameter Ratio

This situation closely resembles the previous rigidity issue. Long tool lengths (including longer tool holders) decrease tool rigidity, creating the potential for chatter and vibration. This can typically be combated with stronger cutting edges, but can also sometimes be corrected with a sharper, free cutting edge. Use the APET unless the results prohibit the use of such a strong edge. The XPET may reduce vibration enough to quiet the operation. Again, use of the toughest grades is typically recommended in long reach applications where chatter or vibration is present. Coolant vs. Dry Machining Most applications using Dapra cutting tools are best performed using dry air blast. Exceptions to this rule include: high-temperature alloys, aluminum and some exceptionally tough stainless steels. When dry machining, use the grades and geometries suggested previously. When using coolants, Dapra recommends using the tougher grades, but with sharper cutting edges (XPET). This allows the heat generated in the cutting zone to be minimized, delaying the effects of thermal shock. Machining Parameters For heavier cuts, tougher substrates should be used, due to the increased pressure and potential vibration created. In lighter cuts, the harder grades provide better performance (speed) and longer tool life. The minimum FPT (feed per tooth) for the APET geometry should be .006". This is to get the chip thickness past the T-land edge preparation, allowing the insert to cut, not rub. The minimum FPT for the XPET insert should be .003". Consequently, lighter cuts (FPT) should not be taken with the APET unless other conditions exist that necessitate the use of the stronger edge. The selection procedure described here will require your careful consideration of several application conditions and insert characteristics. This may take some time, but the cutting results will be well worth your effort.

0 Comments

Leave a Reply. |

AuthorWe've compiled the latest news and technical information about our principals and our market that we hope you find informative! Archives

June 2024

Categories

All

|

|

Browne & Co., Inc.

9605 Tanager Drive Chardon, Ohio 44024 |

© 2024 Browne & Co., Inc. All Rights Reserved

web design by Rapid Production Marketing |

RSS Feed

RSS Feed