ARNO USA represents the US branch of ARNO Werkzeuge, and has individually been in business in North America for over a 100 years as H.B.Rouse and ARNO-ROUSE. ARNO has been manufacturing and selling high-quality products for customers in the machine tooling and metal processing sector since 1962.

ARNO USA stands for German quality at affordable prices.

ARNO-Werkzeuge combines German traditions with state-of-the-art cutting technologies worldwide. They achieve outstanding results through continuous research, development and innovation of ARNO tools. Testing and exploring new materials allows us to introduce new high-performance products year after year, that withstand the wear and tear of high-speed and high-feed machining. Thier modular systems assure enhanced flexibility for your projects.

ARNO USA stands for German quality at affordable prices.

ARNO-Werkzeuge combines German traditions with state-of-the-art cutting technologies worldwide. They achieve outstanding results through continuous research, development and innovation of ARNO tools. Testing and exploring new materials allows us to introduce new high-performance products year after year, that withstand the wear and tear of high-speed and high-feed machining. Thier modular systems assure enhanced flexibility for your projects.

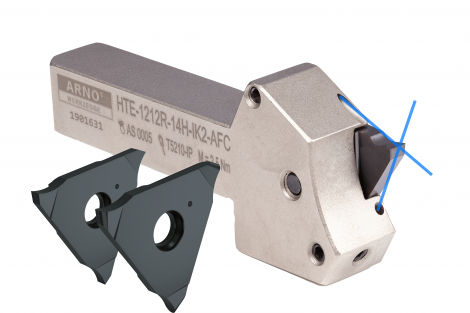

HTE - The Three Edge Precison Grooving System with Through Coolant

|

ARNO has extended it's range of ACS2 coolant capability.

The NEW HTE Precision Grooving System features a three edge insert for better economy and two coolant ports for greater tool life. The inserts are precision ground for the best accuracy and edge definition and are available in widths ranging from .080" (2mm) through 0.236" (6mm) with full radius options as well. This is an unbeatable combination when paired with their Fast Change gang plate where you have the advantage of through the tool coolant with the benefit of 30 second tool changes. How cool is that? The HTE Precision Grooving System is well suited for Swiss machines and traditional CNC lathes. Arno insert grades offer strong performance in Stainless Steel, Titanium, High Temperature Alloys, Steel Alloys, and non ferrous materials such as Aluminum, Brass and Copper. |

Z Axis Extension for Extended Nose Collets

|

Using an extended nose collet?

No problem here, in addition to our offset head turning tool selections, Arno has Z axis extensions that fit right into our GTF and BTF series AWL gang plates. Adaptors for the 12mm tool slots offer 15mm and 20mm offset options while the 16mm tool slot adaptors only offer a 20mm offset. And don't worry, the extensions pick up the through coolant from the gang plate and deliver it to the fixed stop to give you uninterrupted high pressure coolant to the cut zone. |

3D Printed Blades

|

Arno's motto “cool from the start” is about to get a little cooler!

Their quest for industry leading innovation continues as we introduce our line of 3D printed MSA parting modules. They have augmented their world class ACS2 through coolant technology with a range of Arno Specific mount (MSA-S) and Industry Standard mount (MSA-I) modular blades with game changing 3D printed options. How will this benefit your operation? 3D printing eliminates cross-drilled coolant holes that can sometimes meet at sharp or obtuse angles. All of the coolant can now flow unimpeded in the most direct route from the your adaptor to the cutting edge. 3D printing also allows us to produce the flank port in the shape of a triangle which delivers the coolant more effectively to where it needs to be. These features will create one critical benefit; getting more coolant to the cutting edge of your insert than nearly any other parting / grooving tool on the market today. |