Key Features:

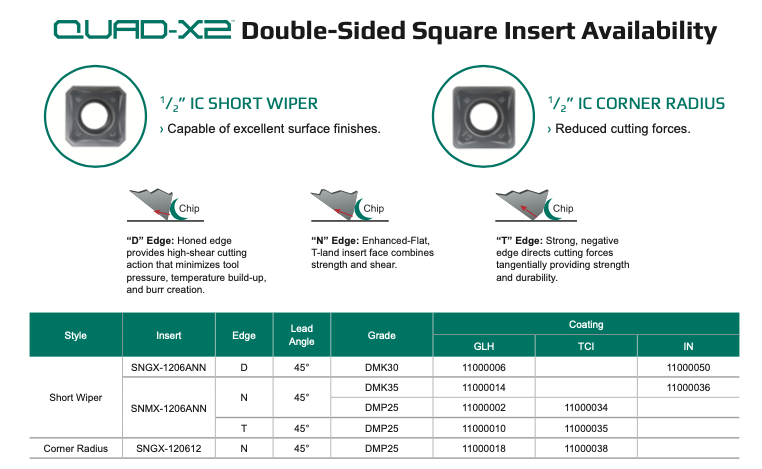

- Optimized 45 Degree Geometry - The Volume3 45 Degree Face Mill boasts a meticulously designed geometry for optimum performance. The 45-degree angle ensures efficient chip evacuation and reduced cutting forces, resulting in enhanced surface finishes and extended tool life.

- Versatile Machining Solutions - Engineered to excel in a variety of materials, from steels to alloys, the Dapra Volume3 provides unparalleled versatility in your machining operations. Its adaptability makes it an ideal choice for a wide range of applications in the aerospace, automotive, and general machining industries.

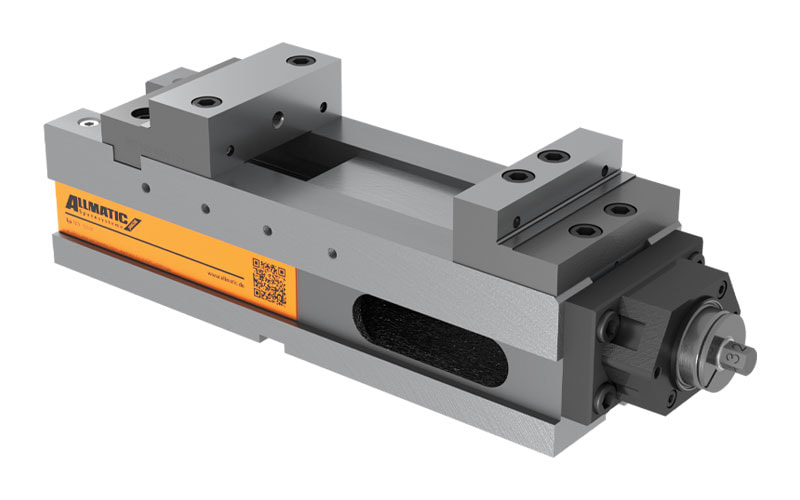

- Precision Engineered for Stability - Stability is key in precision machining, and the Volume3 Face Mill is precision-engineered to deliver exceptional stability during operation. This not only improves machining accuracy but also minimizes vibrations, allowing for smoother and more efficient cutting.

- Advanced Coating Technology - The Dapra Volume3 features state-of-the-art coating technology that enhances tool life and performance. This advanced coating ensures resistance against wear and heat, contributing to sustained reliability and productivity.

- Efficient Chip Evacuation - The innovative design of the face mill facilitates efficient chip evacuation, preventing chip recutting and reducing the risk of tool wear. This ensures consistent and reliable performance even in demanding machining conditions.

Why Choose the Dapra Volume3 45 Degree Face Mill?

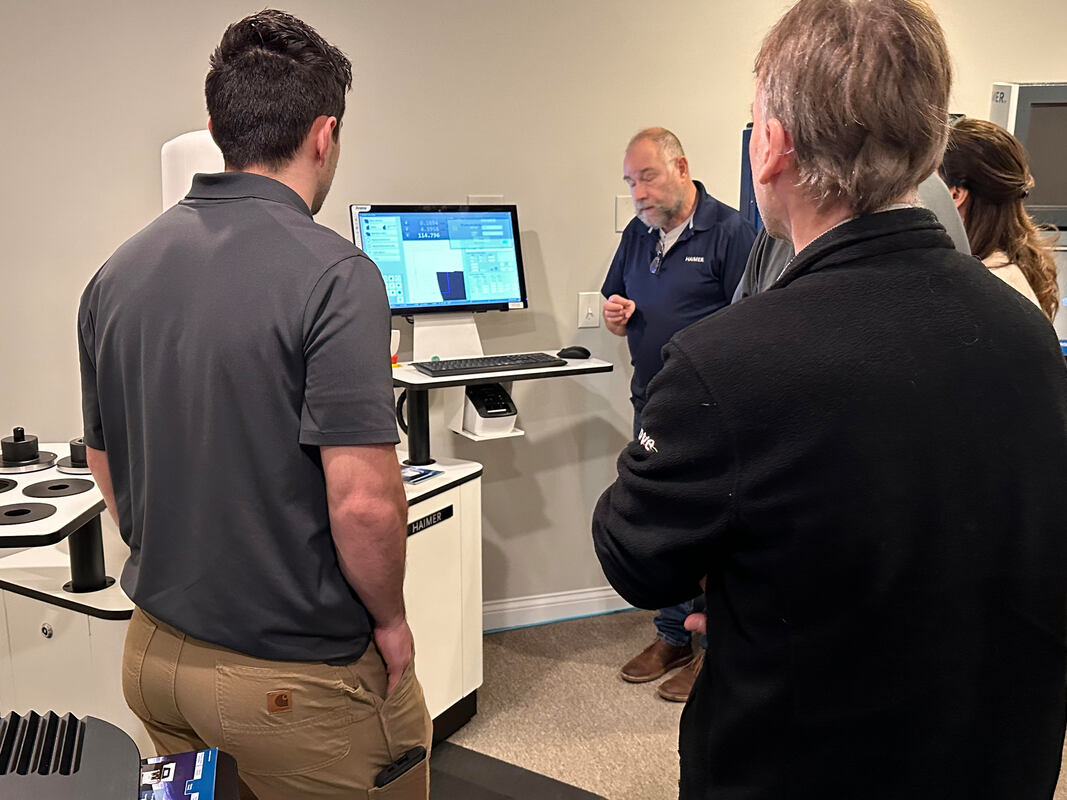

- Enhanced Productivity: Experience faster machining speeds and feeds, boosting overall productivity.

- Superior Surface Finishes: Achieve impeccable surface finishes, meeting the highest quality standards.

- Extended Tool Life: Benefit from the longevity of your cutting tool investment with the Volume3's advanced coating and design.

- Versatile Applications: From roughing to finishing, the Dapra Volume3 is your go-to solution for a wide range of machining applications.

Elevate your machining capabilities and stay ahead of the competition with the Dapra Volume3 45 Degree Face Mill.

Contact Browne & Co now to explore how this revolutionary cutting tool can transform your machining operations.

RSS Feed

RSS Feed